Acoustooptic crystal and transducer bonding structure

A bonding structure and transducer technology, applied in instrumentation, optics, nonlinear optics, etc., can solve problems such as shortening device life, device failure and scrapping, and prolonging device manufacturing cycle, so as to achieve stable device performance and device thermal stress. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

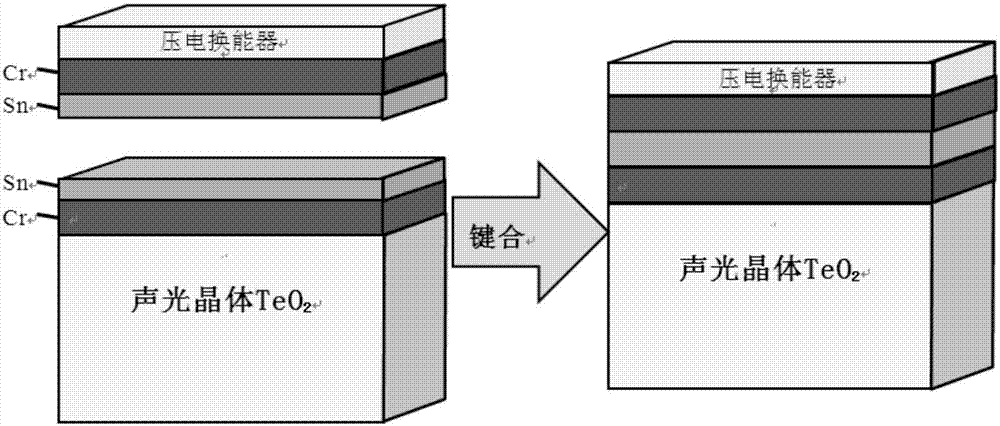

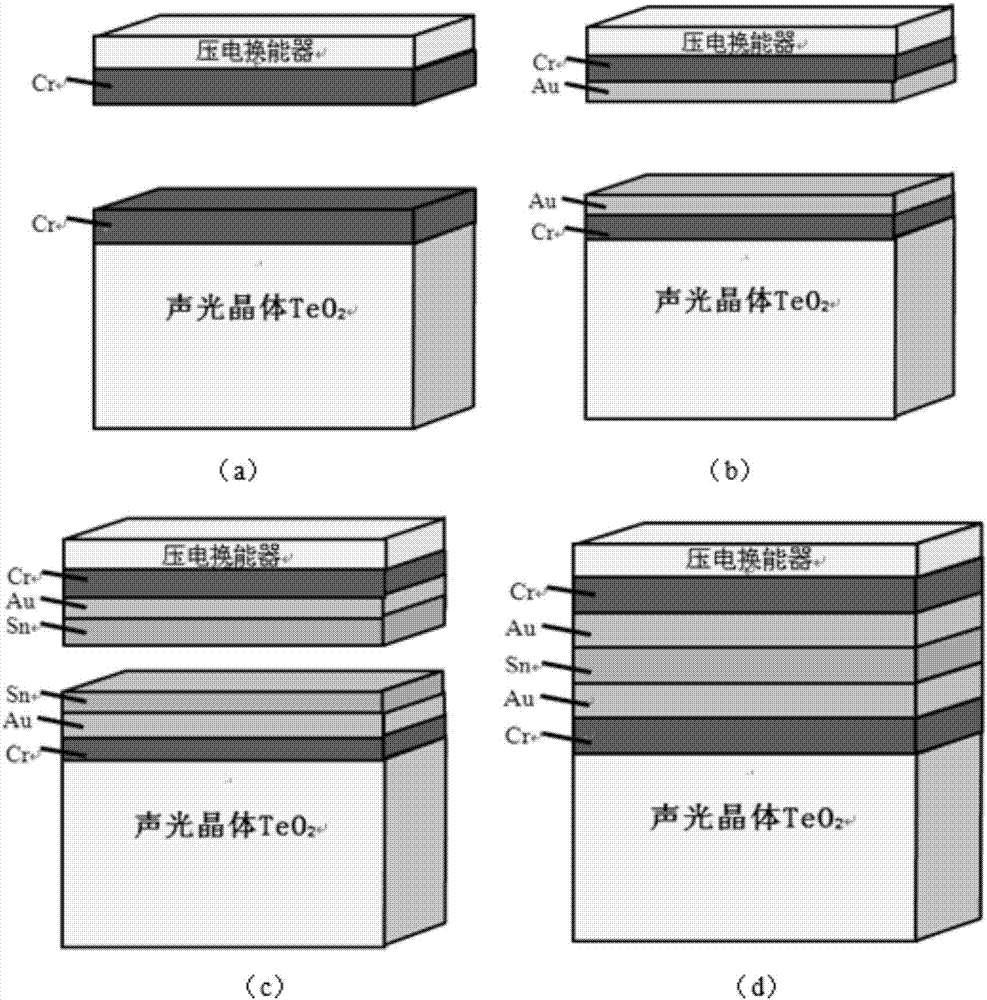

[0029] In order to ensure device reliability and environmental adaptability, the present invention adds a metal transition layer between the acousto-optic crystal and the bottom electrode (Cr) of the transducer and the welding layer. The metal transition layer meets the following requirements: ①High electrical conductivity and good electrical conductivity; ②Good adhesion between the bottom electrode layer Cr and the solder layer Sn; ③The addition of the metal transition layer effectively reduces the thermal stress at the interface between the crystal and the bottom electrode; ④Under the conditions of the first three items are met, the loss of the transducer will not be increased, and the bonding layer meets the acoustic impedance matching. Based on the above considerations, the material of the transition layer is Au (which can satisfy the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com