Production technique of leather garment pocket

A manufacturing process and pocket technology, which is applied in the field of leather pocket manufacturing, can solve problems such as pocket cracking, product quality impact, and leather garment aesthetics, and achieve the effect of improving firmness and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given hereby, and the manufacturing process of the leather pocket of the present invention is described in detail in conjunction with the accompanying drawings as follows:

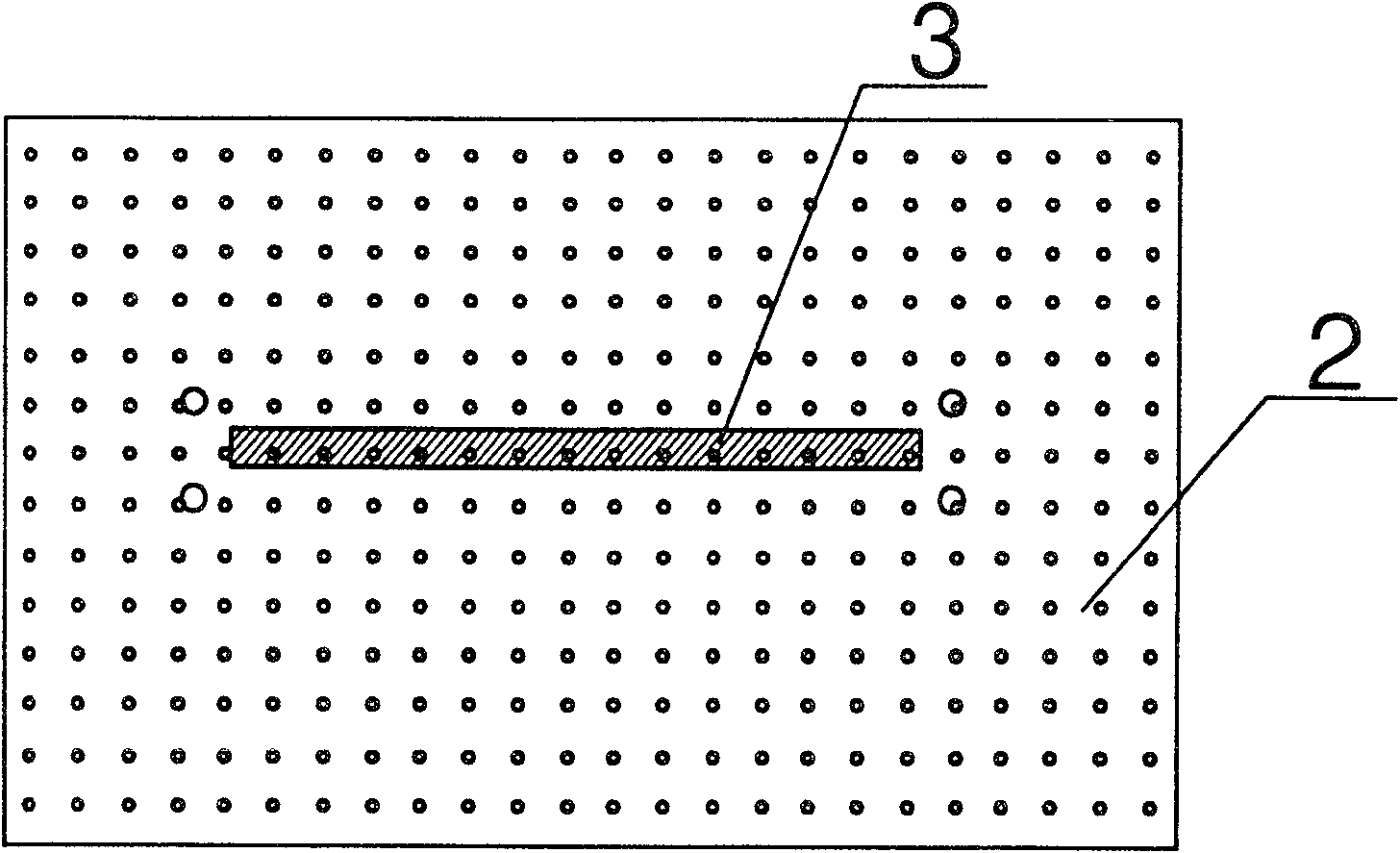

[0034] The manufacturing process of the leather garment pocket of the present invention comprises the following operations (with the pocket being a single opening line pocket, the opening line length is 17cm, and the width is 2cm as an example):

[0035] (1) Determine the position of the pocket on the leather and the length and width of the opening line;

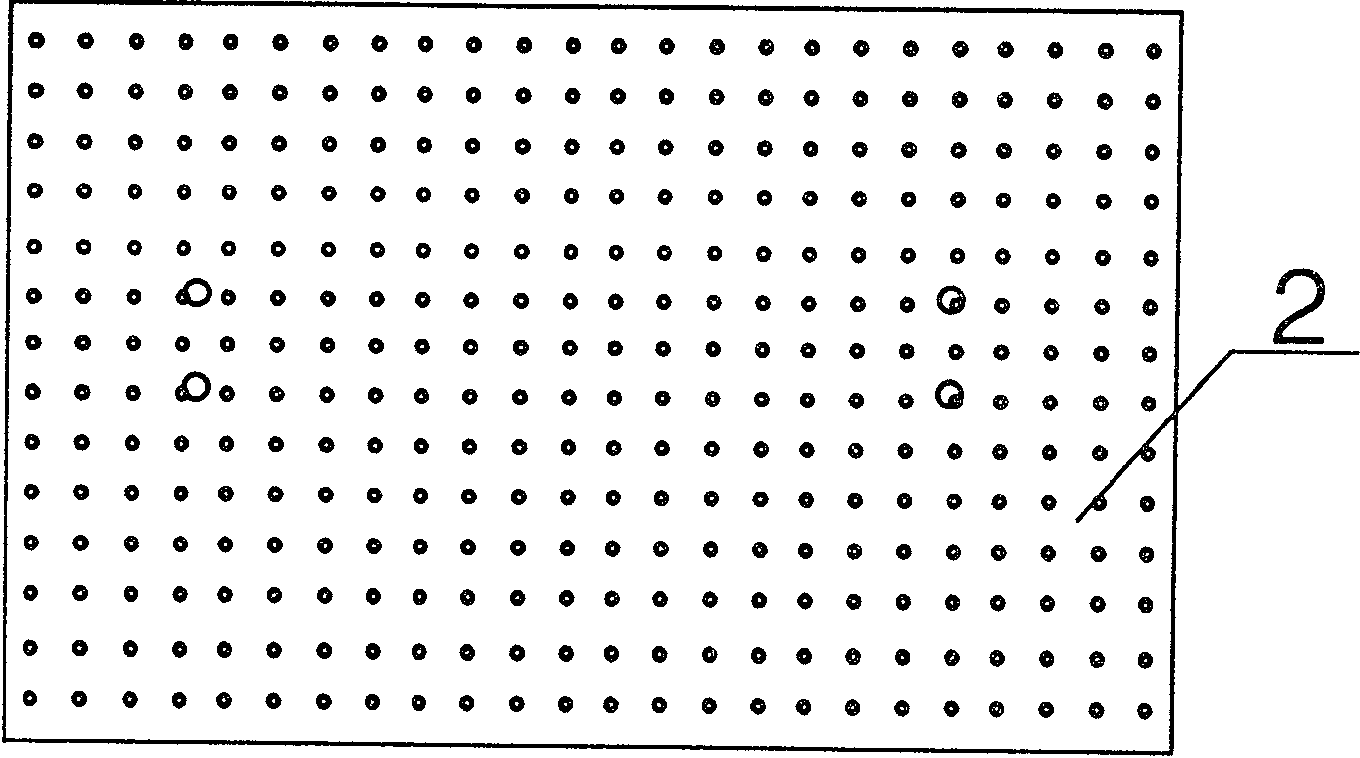

[0036] Such as figure 1 , figure 2 As shown, the process of this step is to point the position of the thread opening at the position where the pocket is set on the front of the leather material. When pointing, use force at the four corners to ensure that the points can be seen on the reverse side.

[0037] (2) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com