Regenerable wet flue gas desulfurization process

A wet flue gas desulfurization and flue gas technology, which is applied in the field of flue gas purification, can solve problems such as large water vapor consumption, and achieve the effects of being beneficial to environmental protection, saving consumption and flexible utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

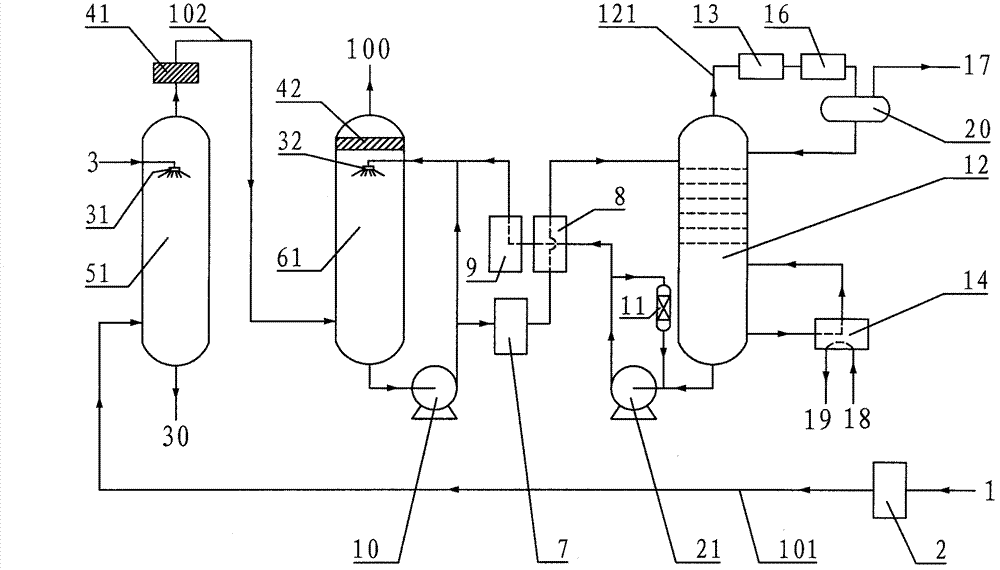

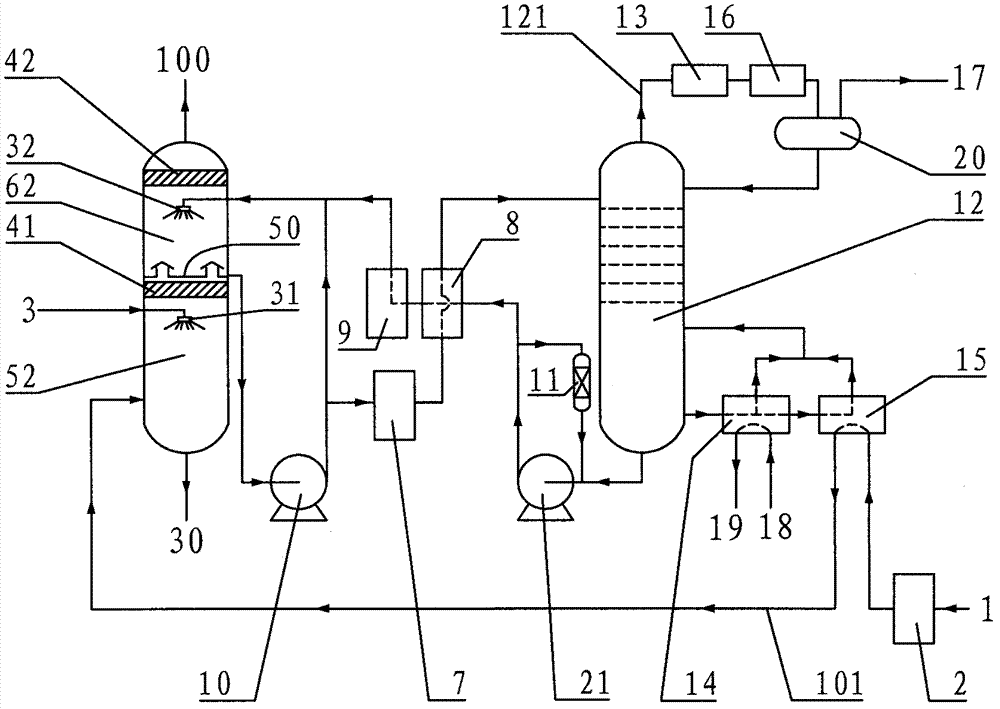

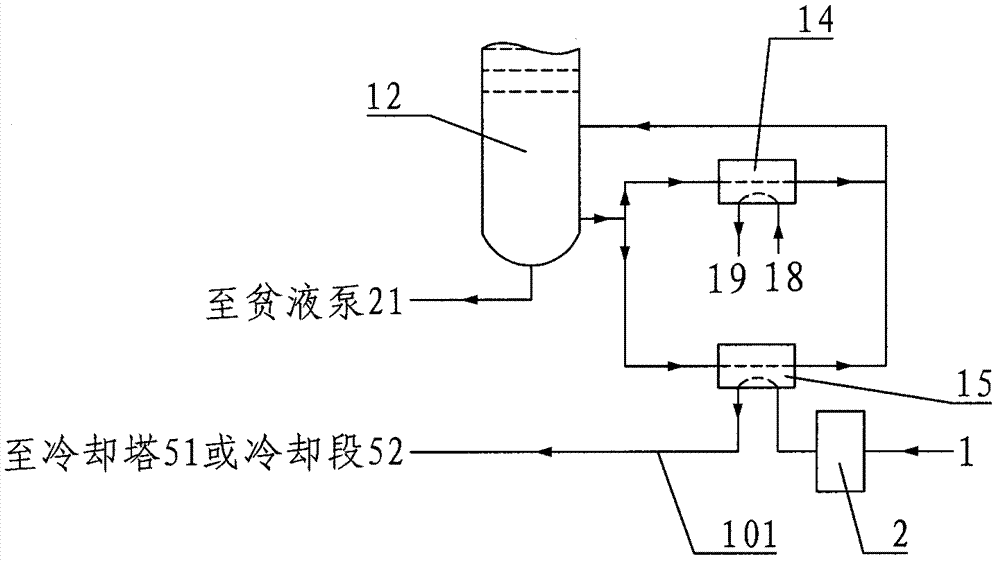

[0035] according to figure 2 The main process flow shown was tested in the laboratory, see the figure 2 as well as figure 1 related instructions. Example with figure 2 The differences in the process flow shown are: ① using Figure 4 The fourth regeneration tower reboil process shown (see the Figure 4 Relevant instructions), the exothermic flue gas flowing out of the flue gas heat exchanger 22 enters the lower part of the cooling section 52 through the flue gas pipeline 101; After the pipeline 101, it is not subjected to dust removal; ③ No filter 7 is installed, and the rich liquid flowing to the lean-rich liquid heat exchanger 8 does not pass through the filter 7 to remove the contained solid impurities, and directly enters the lean-rich liquid heat exchanger 8; ④ No setting In the thermally stable salt remover 11 , all the lean liquid flowing out from the lean liquid pump 21 enters the lean-rich liquid heat exchanger 8 .

[0036] The main equipment or parts used in ...

Embodiment 4

[0039] Examples 4 to 5 use steam as the reboil heat source medium of hot water or steam reboiler 14, and the specific consumption of water steam is shown in Table 3. As can be seen from Table 3, after adopting the decompression regeneration scheme of the present invention, every 1 kilogram of sulfur dioxide is regenerated, and the consumption of steam is 12.36 kilograms (embodiment 4) and 12.98 kilograms (embodiment 5); per ton of sulfur dioxide, the water vapor consumption is 12.36 tons (Example 4) and 12.98 tons (Example 5), both of which are lower than the water vapor consumption of the existing renewable wet flue gas desulfurization process.

[0040] Table 1

[0041]

[0042] Table 2

[0043]

[0044] table 3

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com