Grid drive circuit for metallic oxide semiconductor field effect transistor to output linear current

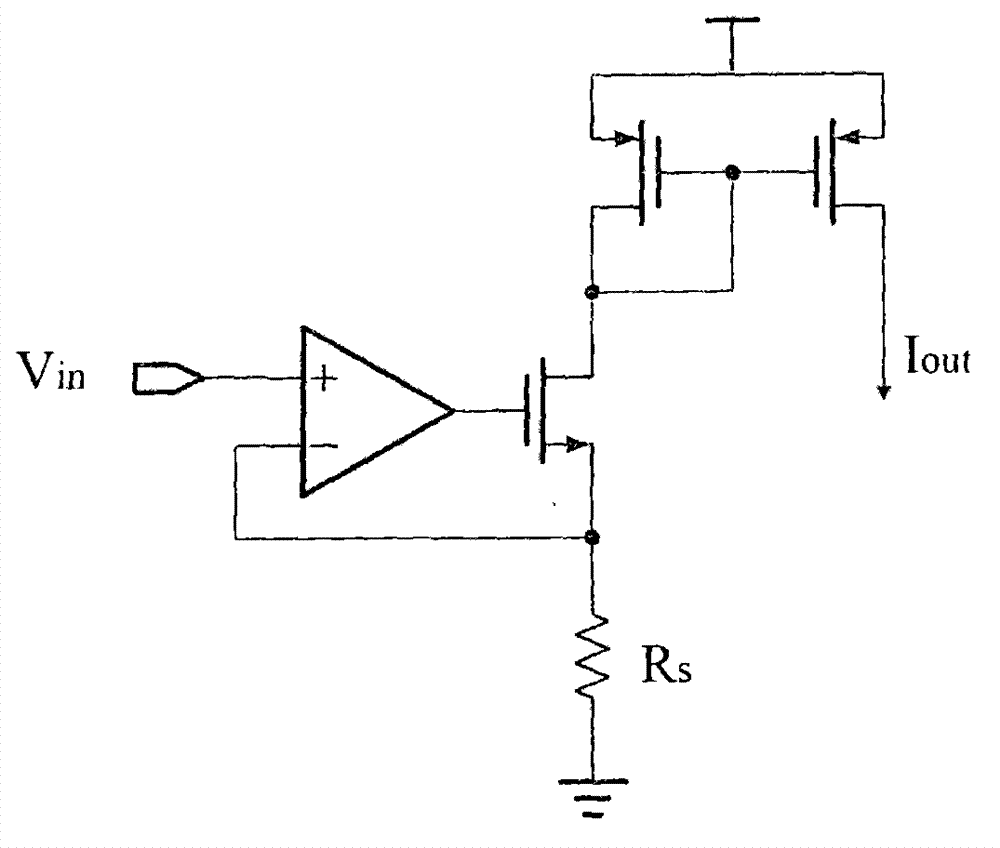

A technology of oxide semiconductors and field effect transistors, which is applied in the field of metal oxide semiconductor field effect transistor voltage-to-current conversion drive circuits, can solve problems affecting output accuracy, cost increase, and process differences affecting circuit linearity, etc., to achieve circuit The effect of simple components and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

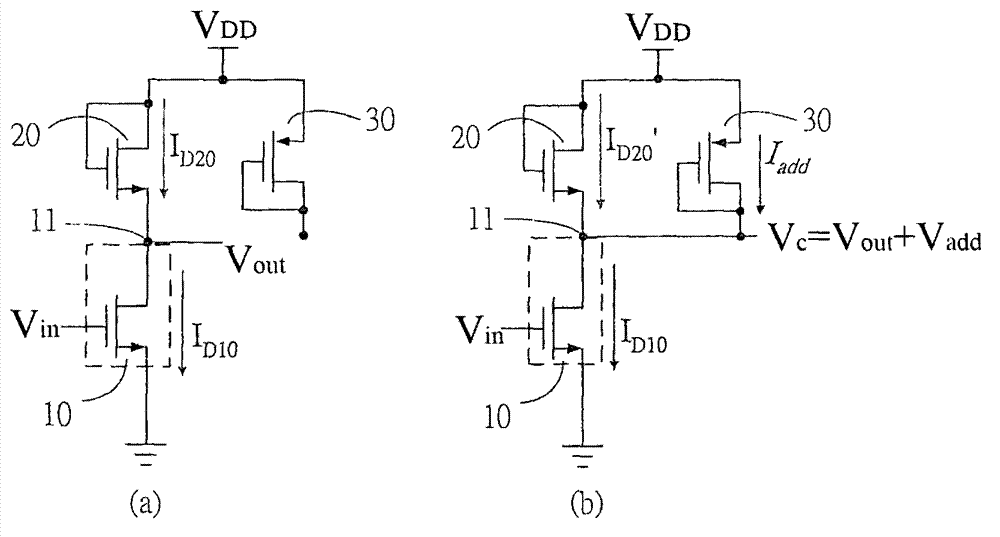

[0037] The detailed technical contents of the present invention will be clearly presented by presenting the embodiments matched with the illustrations. In the description, the size of the metal oxide semiconductor field effect transistor is defined as the (width / length) ratio of the element channel, expressed in (W / L) XX Indicates that the numbers subscripted by each symbol " XX ” is the component number in the illustration.

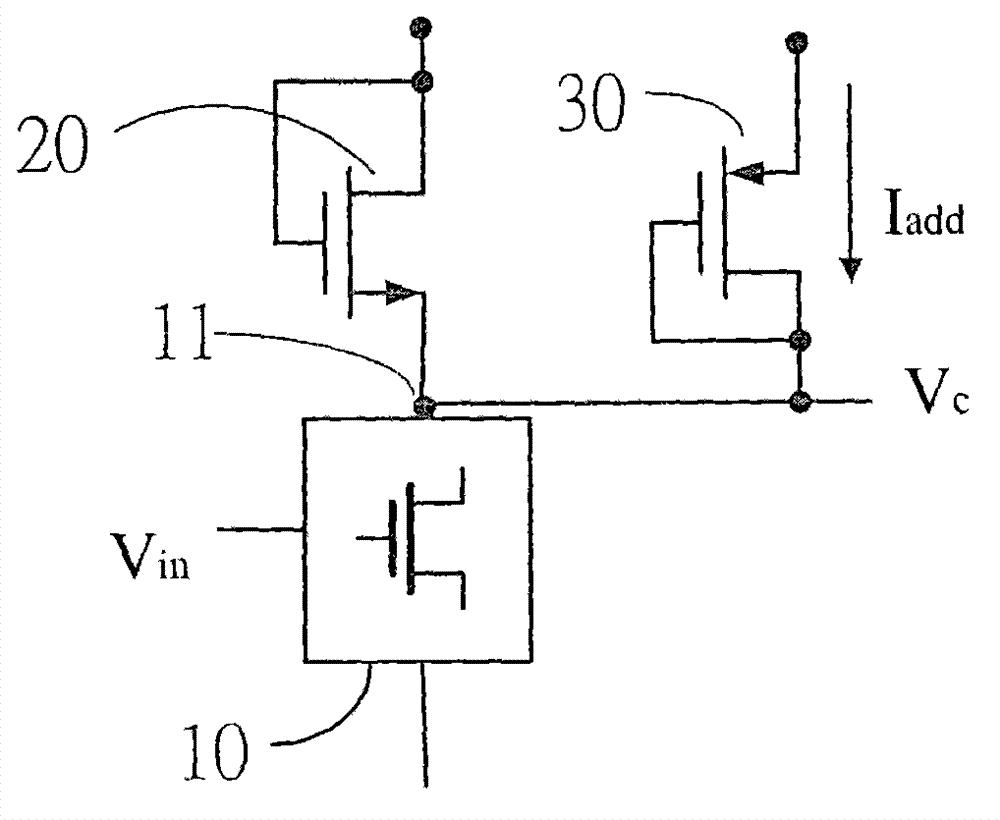

[0038] see figure 2 , is the basic structure embodiment of the gate drive circuit of the present invention that makes the metal oxide semiconductor field effect transistor output linear current, a gate terminal is connected to the drain terminal N-type metal oxide semiconductor field effect transistor 20, a gate terminal is connected to the drain terminal The P-type metal oxide semiconductor field effect transistor 30 connected to the extreme, a voltage input circuit 10; the voltage input circuit 10 includes at least one metal oxide semiconductor fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com