Automobile thermoelectric power generation device

A technology of thermoelectric power generation and thermoelectric power generation sheet, which can be used in muffler devices, exhaust devices, generators/motors, etc., can solve the problems of difficult reuse and inability to concentrate waste heat, and achieve the effect of light weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

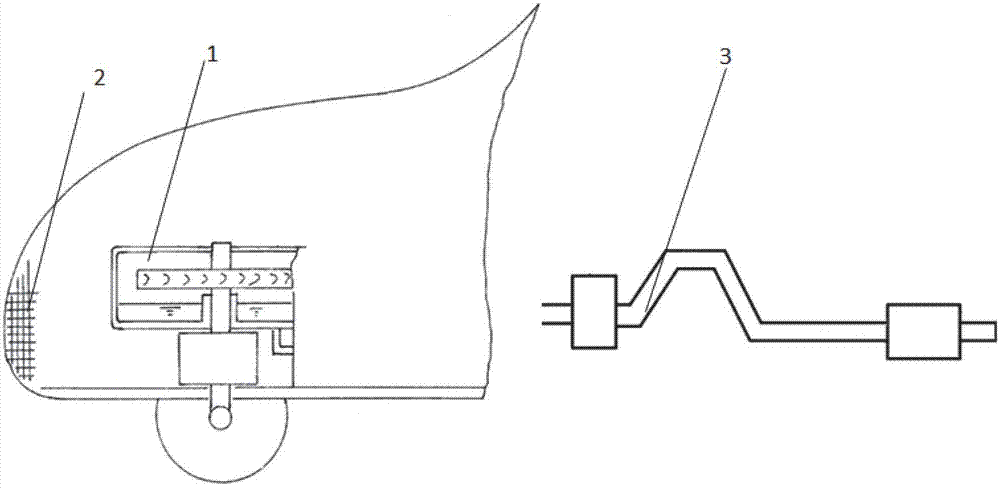

[0016] like figure 1 As shown, the engine 1 of the automobile is the power source of the automobile, and drives the transmission mechanism to drive the automobile through combustion. The combustion temperature inside the engine is generally above 1300 degrees Celsius, so the temperature of the engine casing is very high, which is very different from the temperature of the outside air. Very suitable for thermoelectric power generation. The exhaust pipe 3 of the automobile directly discharges the exhaust gas after engine combustion, and its temperature changes depending on the engine speed, and is generally also more than 300 degrees and is also suitable for thermoelectric power generation. In addition, the temperature of the engine radiator 2 of the automobile is also about 100 degrees Celsius, which is also very suitable for thermoelectric power generation.

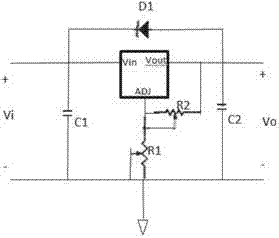

[0017] The invention uses semiconductor thermoelectric power generation components to assemble a semiconductor thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com