Bionic construction of metal-foam-based oil-water separation material

A metal foam, oil-water separation technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor separation method effect, difficult oil and material recovery, difficult removal, etc., to achieve low cost and easy raw materials The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

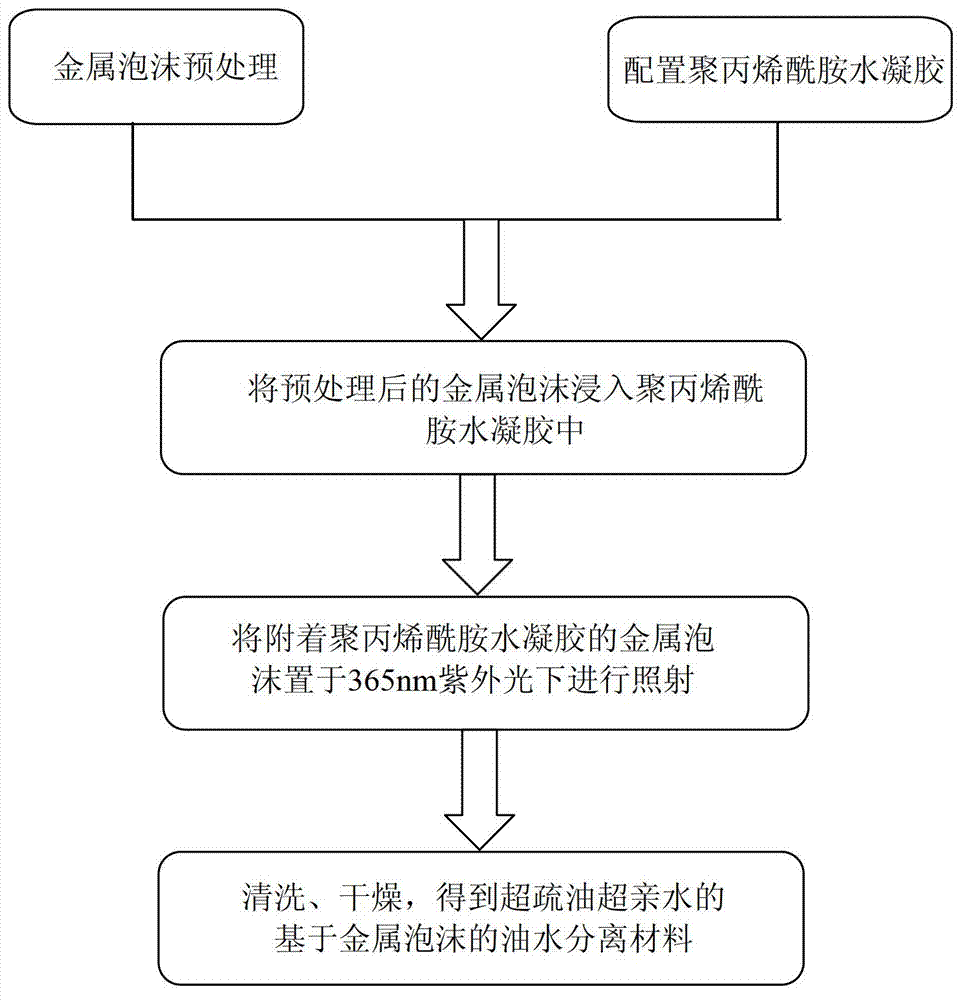

[0028] The second step, the preparation of polyacrylamide hydrogel: measure 20 ~ 70ml deionized and pour it into a beaker, according to the mass ratio of 50:1.5:1:0.5, weigh acrylamide, N,N'-methylene Bisacrylamide, 2,2-diethoxyacetophenone, and polyacrylamide were poured into the above-mentioned beaker filled with deionized water in sequence, and stirred evenly until the solution in the beaker became a transparent colloid, and polyacrylamide was obtained. Acrylamide hydrogel.

[0029] The third step is to immerse the pretreated metal foam in the first step into the prepared polyacrylamide hydrogel, and soak it at room temperature for 0.5-5 minutes (preferably 3 minutes), so that the polyacrylamide hydrogel is completely attached to the After the metal foam is on, take out the metal foam and place the metal foam in a watch glass.

[0030] The fourth step is to use the method of photoinitiated polymerization to irradiate the metal foam in the watch glass under 365nm ultraviole...

Embodiment 1

[0034] Apply the bionic structure proposed by the present invention to build the oil-water separation material based on metal foam, select nickel metal foam, and its method includes the following steps:

[0035] 1. Metal foam pretreatment: take a beaker, pour deionized water, immerse nickel metal foam (30mm×50mm×1mm) in deionized water, put the beaker into an ultrasonic device and ultrasonically clean it for 5 minutes to clean the metal Stains on the surface of the foam; pour out the cleaning solution, pour absolute ethanol (analytical alcohol, ethanol mass fraction ≥ 99.7%) into the beaker, continue to ultrasonically clean the metal foam for 20 minutes, remove the grease on the metal foam, take it out and dry it (oven temperature 60°C), put it in 1mol / L dilute nitric acid solution for 10 minutes, take it out and dry it (oven temperature 60°C) for use;

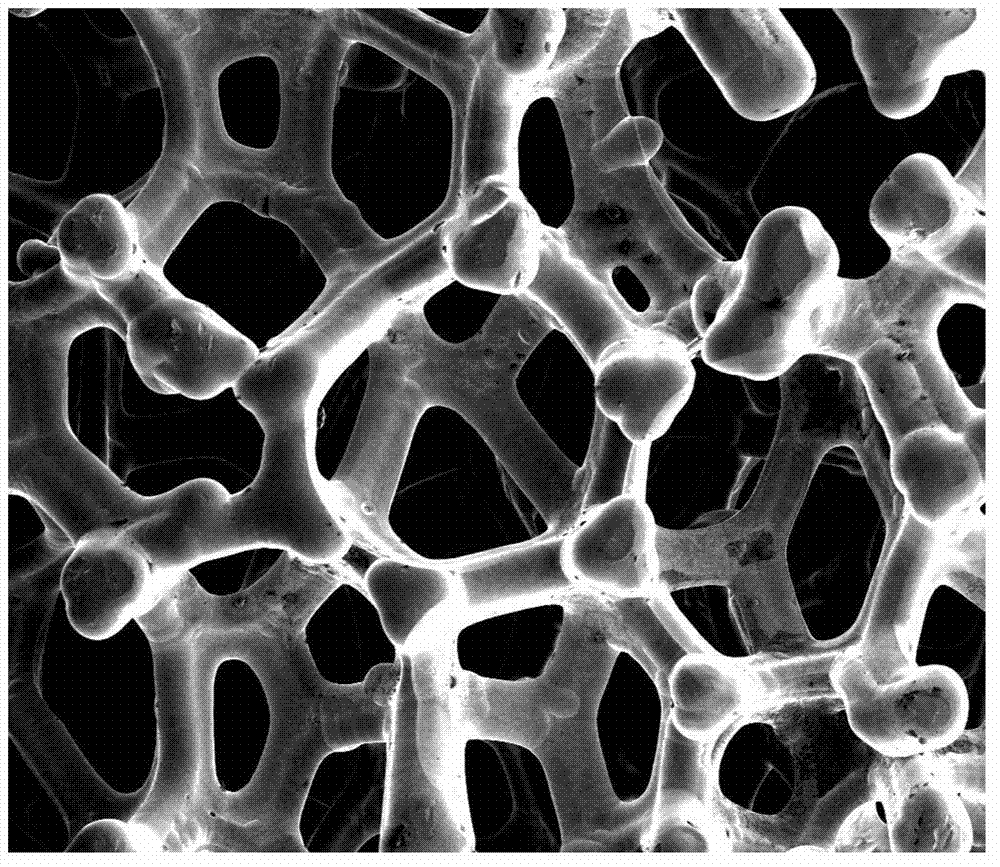

[0036] Using dilute acid to corrode the surface of the metal foam, the purpose is to make the structure of the metal foam ro...

Embodiment 2

[0043] The bionic construction proposed by the present invention is based on the oil-water separation material of nickel metal foam, and its method comprises the following steps:

[0044] 1. Metal foam pretreatment: take a beaker, pour deionized water, immerse nickel metal foam (20mm×40mm×2mm) in deionized water, put the beaker into an ultrasonic device and ultrasonically clean it for 10 minutes to clean the metal Stains on the surface of the foam; pour out the cleaning solution, pour absolute ethanol (analytical alcohol, ethanol mass fraction ≥ 99.7%) into the beaker, continue to ultrasonically clean the metal foam for 30 minutes, remove the grease on the metal foam, take it out and dry it (oven temperature 70°C), corrode in 2mol / L dilute hydrochloric acid solution for 6 minutes, take it out and dry it (oven temperature 70°C) for use;

[0045] 2. Preparation of polyacrylamide hydrogel: Measure 40ml of deionized water and pour it into a beaker. According to the mass ratio of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com