Functional graphene oxide modified composite gel electrolyte and preparation method thereof

A graphene modification and composite gel technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problem of low ion conductivity and achieve the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

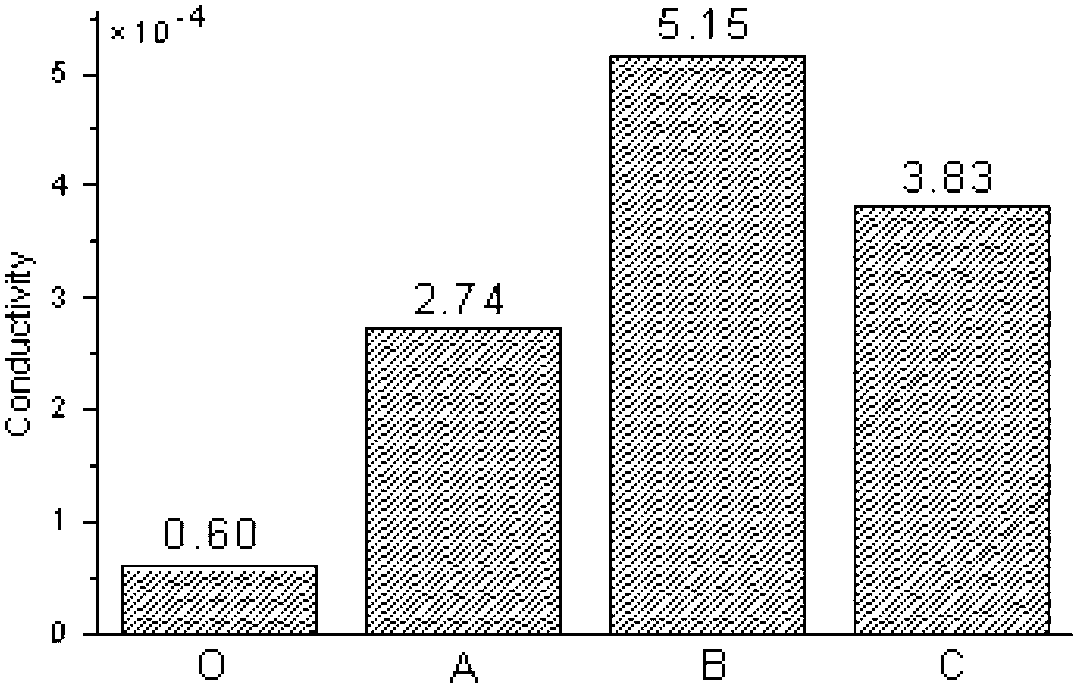

Examples

Embodiment 1

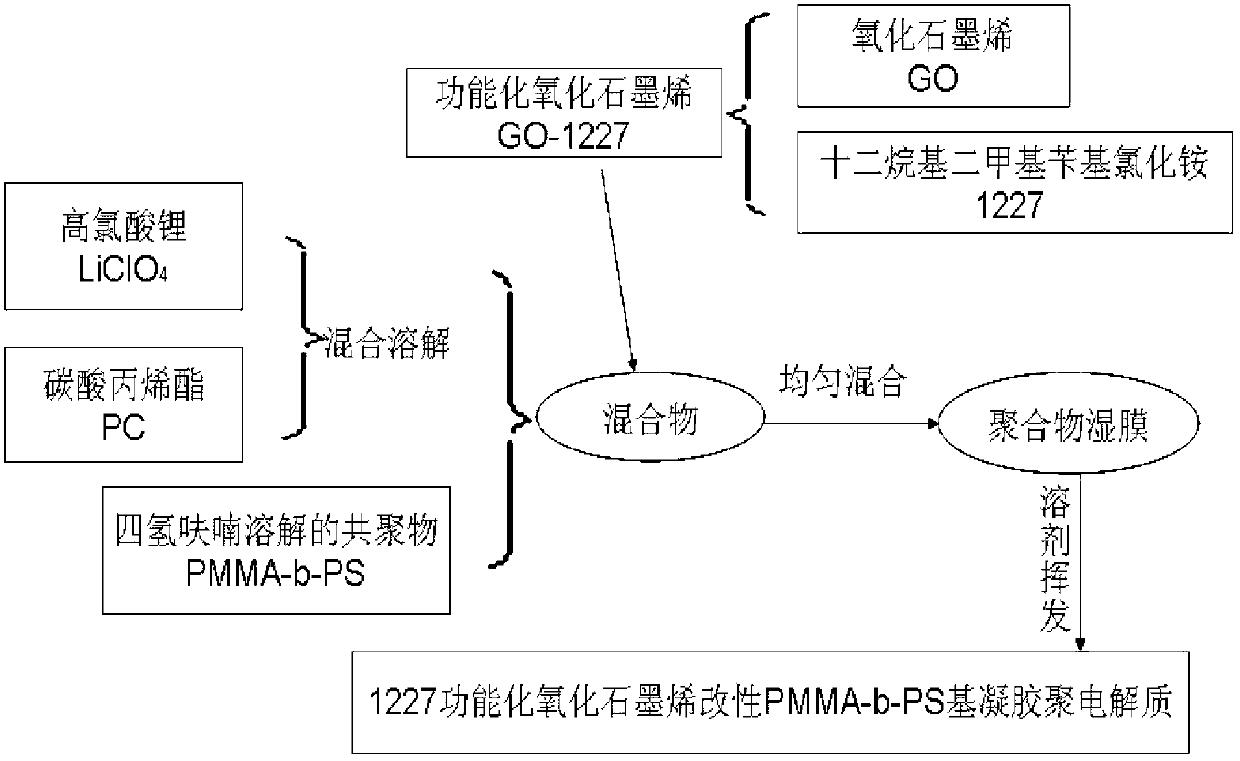

[0024] Implementation example 1: the reaction flow diagram is as figure 2 shown.

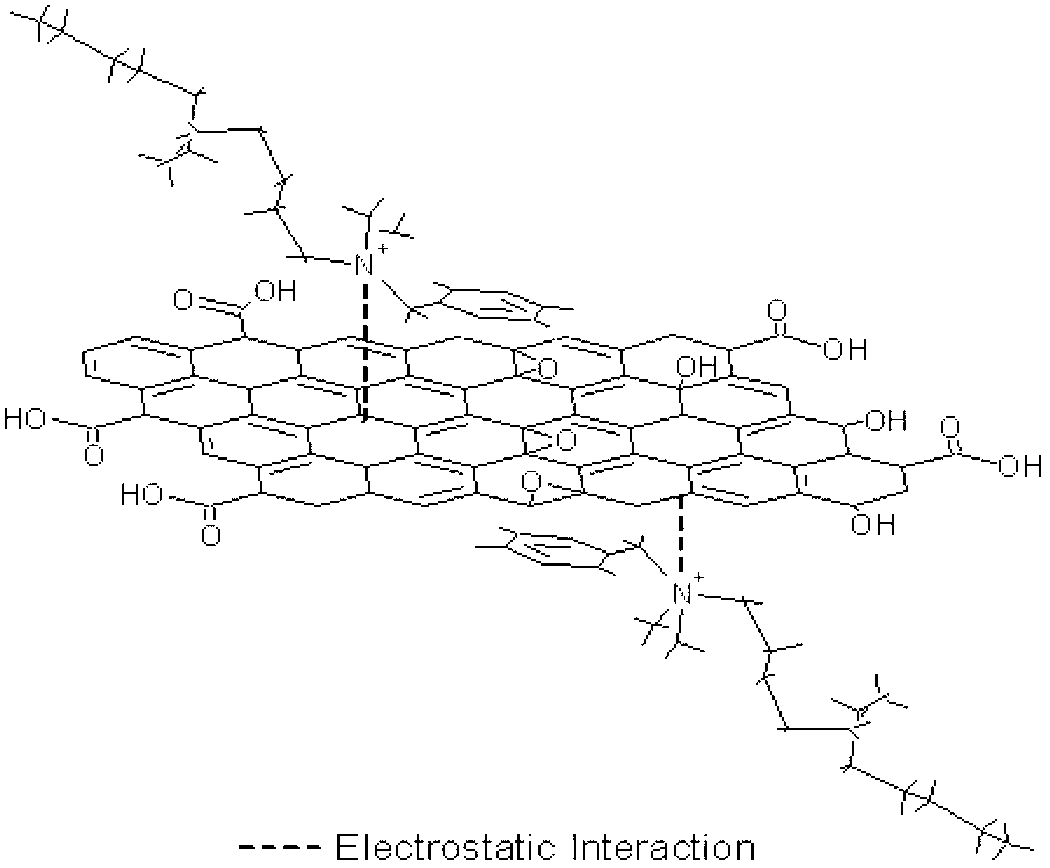

[0025] Step 1: Preparation of functionalized graphene oxide: 1 part of graphene oxide flake solid prepared by the improved Hummers method is mixed with water to form a suspension of 0.5 mg / ml, and graphite oxide can be obtained after ultrasonically assisted dispersion for 30 minutes Alkene hydrosol. Add 1 part of an aqueous solution of dodecyldimethylbenzyl ammonium chloride, the concentration of which is 30%, and then stir at 25° C. for 20 minutes. Afterwards, filter with a G3 sand core funnel and wash until there is no chloride ion (detected with silver nitrate solution). Dry in an oven at 30°C to obtain a functionalized graphene oxide solid.

[0026] Step 2: Polymer preparation: Ethyl methacrylate homopolymer was prepared by atom transfer radical polymerization. Wherein the number average molecular weight of the homopolymer is 15780.

[0027] Step 3: Preparation of functionalized graphe...

Embodiment 2

[0029] Step 1: Preparation of functionalized graphene oxide: 1 part of graphene oxide flake solid prepared by the improved Hummers method is mixed with water to form a suspension of 0.5 mg / ml, and graphite oxide can be obtained after ultrasonically assisted dispersion for 30 minutes Alkene hydrosol. Add 1 part of an aqueous solution of dodecyldimethylbenzyl ammonium chloride, the concentration of which is 30%, and then stir at 25° C. for 20 minutes. Afterwards, filter with a G3 sand core funnel and wash until there is no chloride ion (detected with silver nitrate solution). Dry in an oven at 30°C to obtain a functionalized graphene oxide solid.

[0030] Step 2: Preparation of polymer: Methyl methacrylate homopolymer was prepared by atom transfer radical polymerization. Wherein the number average molecular weight of the homopolymer is 15000.

[0031] Step 3: Preparation of functionalized graphene oxide modified composite gel electrolyte: 1 part of functionalized graphene oxi...

Embodiment 3

[0033] Step 1: Preparation of functionalized graphene oxide: 1 part of graphene oxide flake solid prepared by the improved Hummers method is mixed with water to form a suspension of 0.5 mg / ml, and graphite oxide can be obtained after ultrasonically assisted dispersion for 30 minutes Alkene hydrosol. Add 1 part of an aqueous solution of dodecyldimethylbenzyl ammonium chloride, the concentration of which is 30%, and then stir at 25° C. for 20 minutes. Afterwards, filter with a G3 sand core funnel and wash until there is no chloride ion (detected with silver nitrate solution). Dry in an oven at 30°C to obtain a functionalized graphene oxide solid.

[0034] Step 2: Preparation of polymer: A block copolymer of ethyl methacrylate and polystyrene was prepared by atom transfer radical polymerization, with a number-average molecular weight of 32860 and a ratio of 1:1 to the first stage.

[0035] Step 3: Preparation of functionalized graphene oxide modified composite gel electrolyte: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com