Copper-clad steel combined special-shaped contact wire for electrified railway

A technology for electrified railways and special-shaped contacts, which is applied in the direction of circuits, electrical components, conductors, etc., can solve the problems of being widely recognized, difficult to manufacture and use, and difficult to reach the ideal level, and achieve simple manufacture, good promotion and use value, The effect of reducing the amount of wire rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

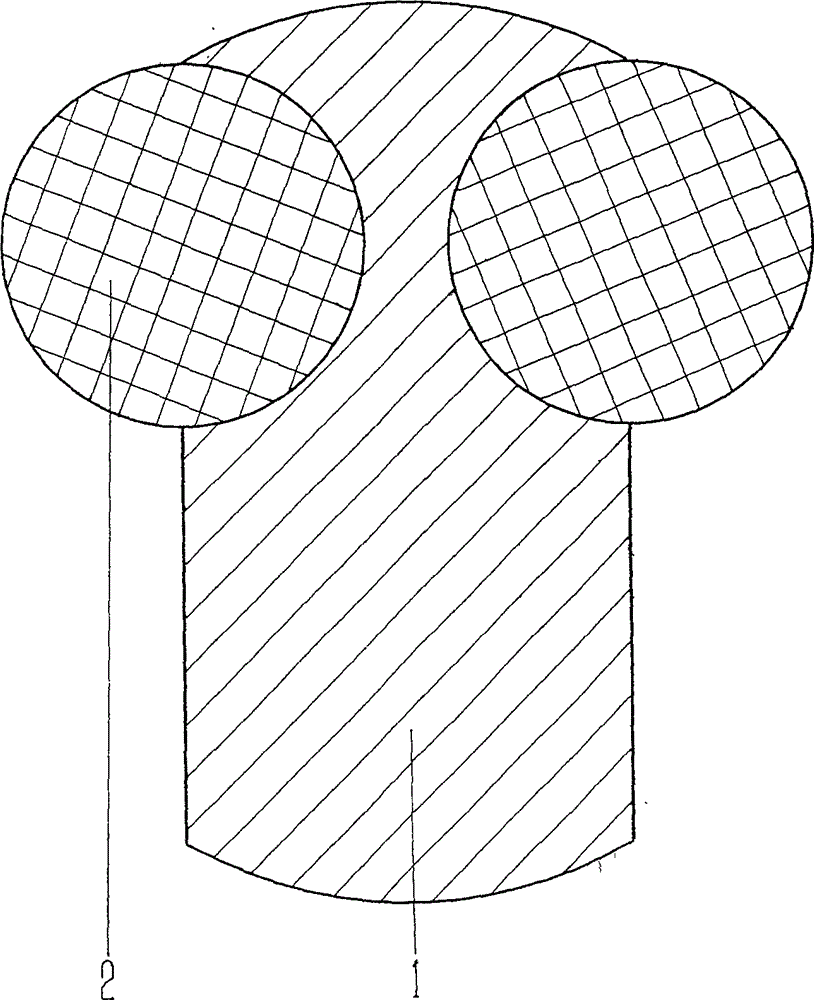

[0014] like figure 1 As shown, the electrified railway steel-clip-copper combined special-shaped contact wire is realized by the combination of the conductive part 1 and the steel cable part 2. The conductive part 1 is made of a copper-silver alloy with outstanding conductivity and wear resistance. The upper and lower sides are concentric and correspondingly arc-shaped with the same diameter. Two concave semicircular grooves are designed on the upper parts of the two straight sides. The steel cable portion 2 is made of strong, anti-corrosion, prestressed spring steel, and its diameter is equal to the semicircular groove of the conductive portion 1 .

[0015] When in use, the conductive part 1 and the steel cable part 2 are spread, hoisted and leveled synchronously, the steel cable part 2 is embedded in the groove of the conductive part 1, and the special clip is fixed as a whole for hanging.

[0016] Except for the technical features described in the instructions, all are kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com