Flat plate collector with worm pipes

A flat-plate heat collector and scroll-type technology, which is applied to solar heat collectors, solar heat collectors using working fluids, heating devices, etc., can solve problems such as easy falling off, large thermal resistance, and high price, and achieve improved Product reliability, improved heat transfer effect, and the effect of avoiding thermal resistance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

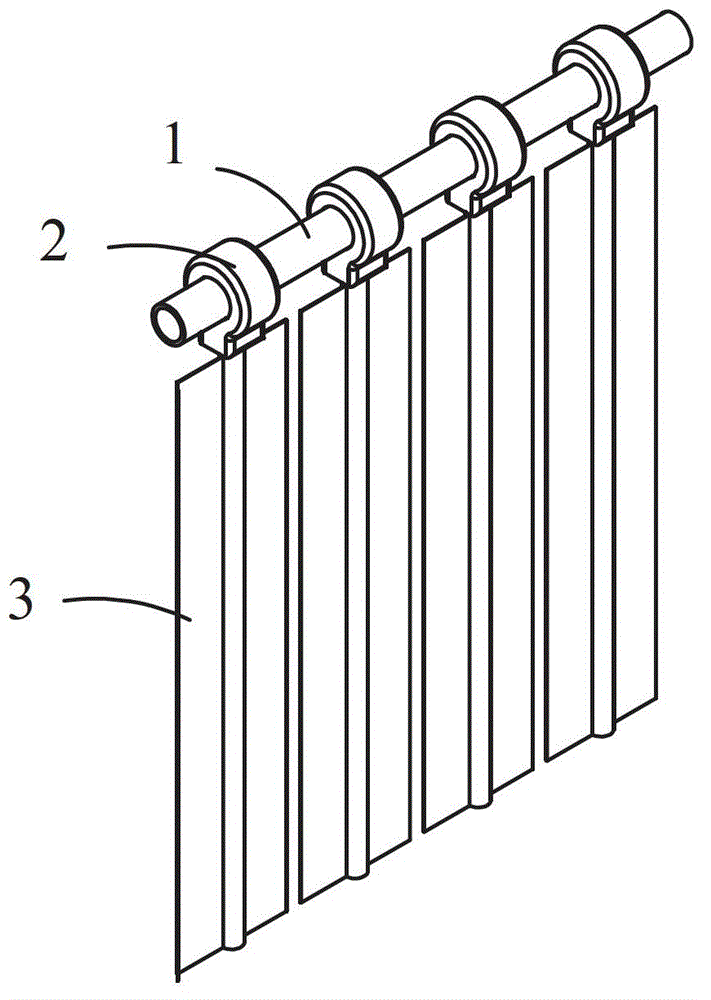

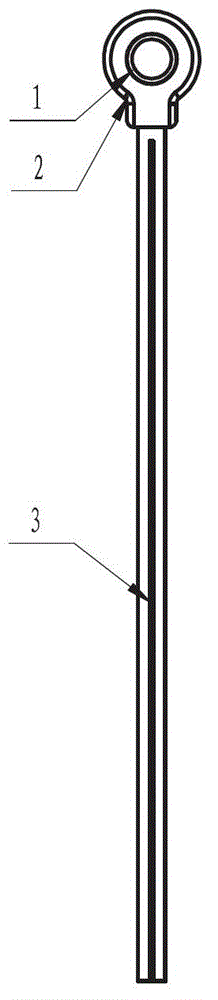

[0022] The spiral tube type heat pipe flat plate heat collector of the present invention includes an outer frame, and a high light-transmitting tempered glass is inlaid on the outer frame, and a heat-absorbing plate core is installed under the tempered glass, please refer to the same time Figure 1 to Figure 4 As shown, the heat-absorbing plate core includes heat exchange tubes 1 , heat exchange volutes 2 , and heat collection tubes 3 with the same number as the heat exchange volutes 2 . The heat collecting tube 3 includes a heat collecting flow channel 32 and heat collecting fins 34 arranged on both sides of the heat collecting flow channel 32 .

[0023] The heat exchange tube 1 passes through several heat exchange volutes 2, and the upper part of each heat collection flow channel 32 communicates with a corresponding heat exchange volute 2, and the lower part of each heat collection flow channel 32 is sealed separately, and the heat exchange tube 1 , the heat exchange volute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com