Super-strength high-toughness wear resistant steel plate and production method thereof

A technology of wear-resistant steel plate and steel plate, which is applied in the field of wear-resistant steel, can solve the problems of low welding performance, mechanical performance, poor welding performance and machining performance, etc., and achieve the effect of excellent mechanical performance, good mechanical performance and short production process

Active Publication Date: 2015-03-04

BAOSHAN IRON & STEEL CO LTD

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] CN1140205A discloses a medium-carbon and medium-alloy wear-resistant steel, the content of carbon and alloy elements (Cr, Mo, etc.) is much higher than that of the present invention, which will inevitably lead to poor welding performance and machinability

[0007] CN1865481A discloses a kind of bainite wear-resistant steel, compared with the present invention, its alloy element (Si, Mn, Cr, Mo etc.) content is higher, weldability, mechanical property are lower

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

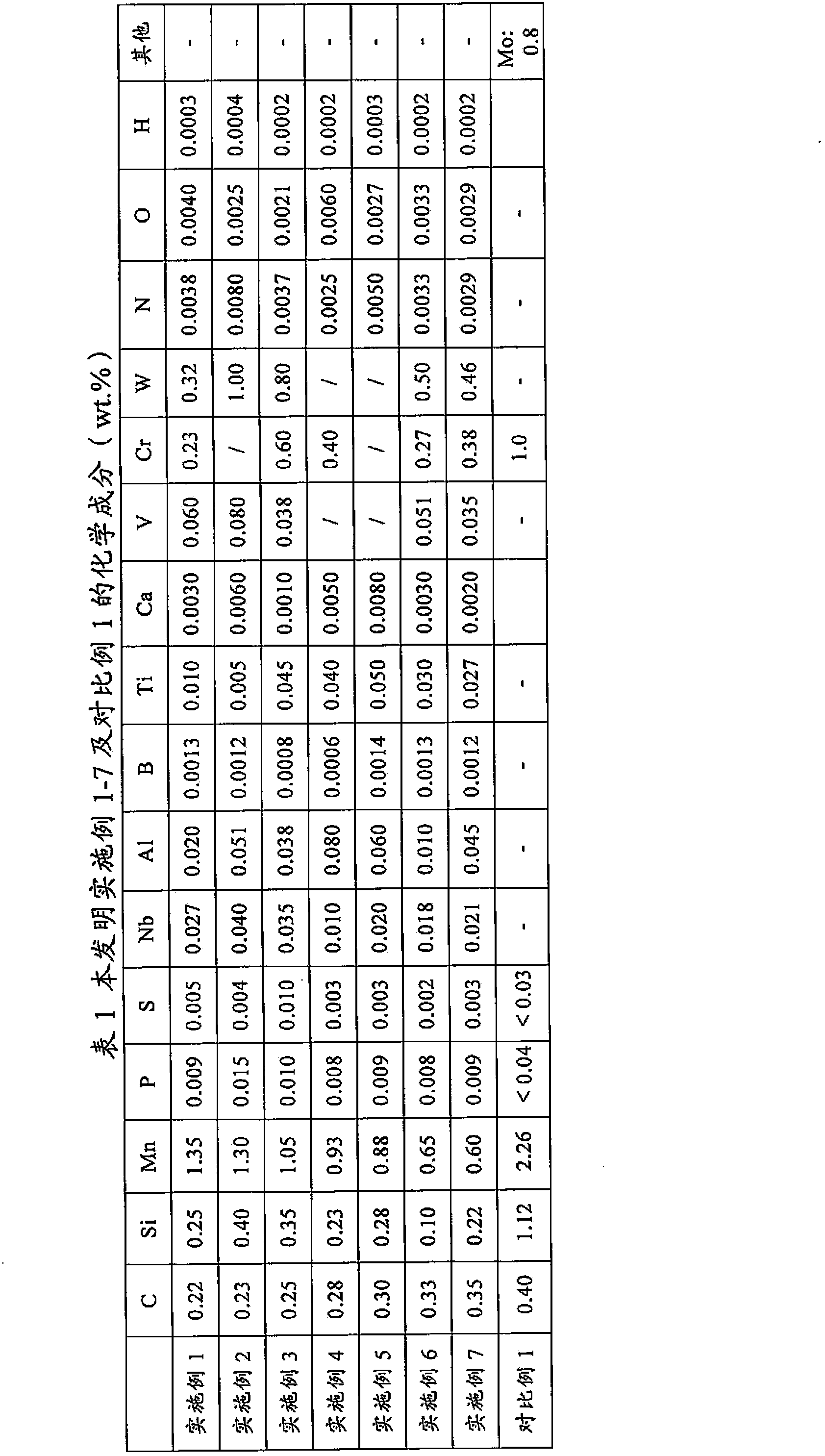

[0046] Table 1 shows the mass percentage distribution of chemical elements in the steel plates of Examples 1-7 of the present invention and Comparative Example 1 (patent CN1865481A).

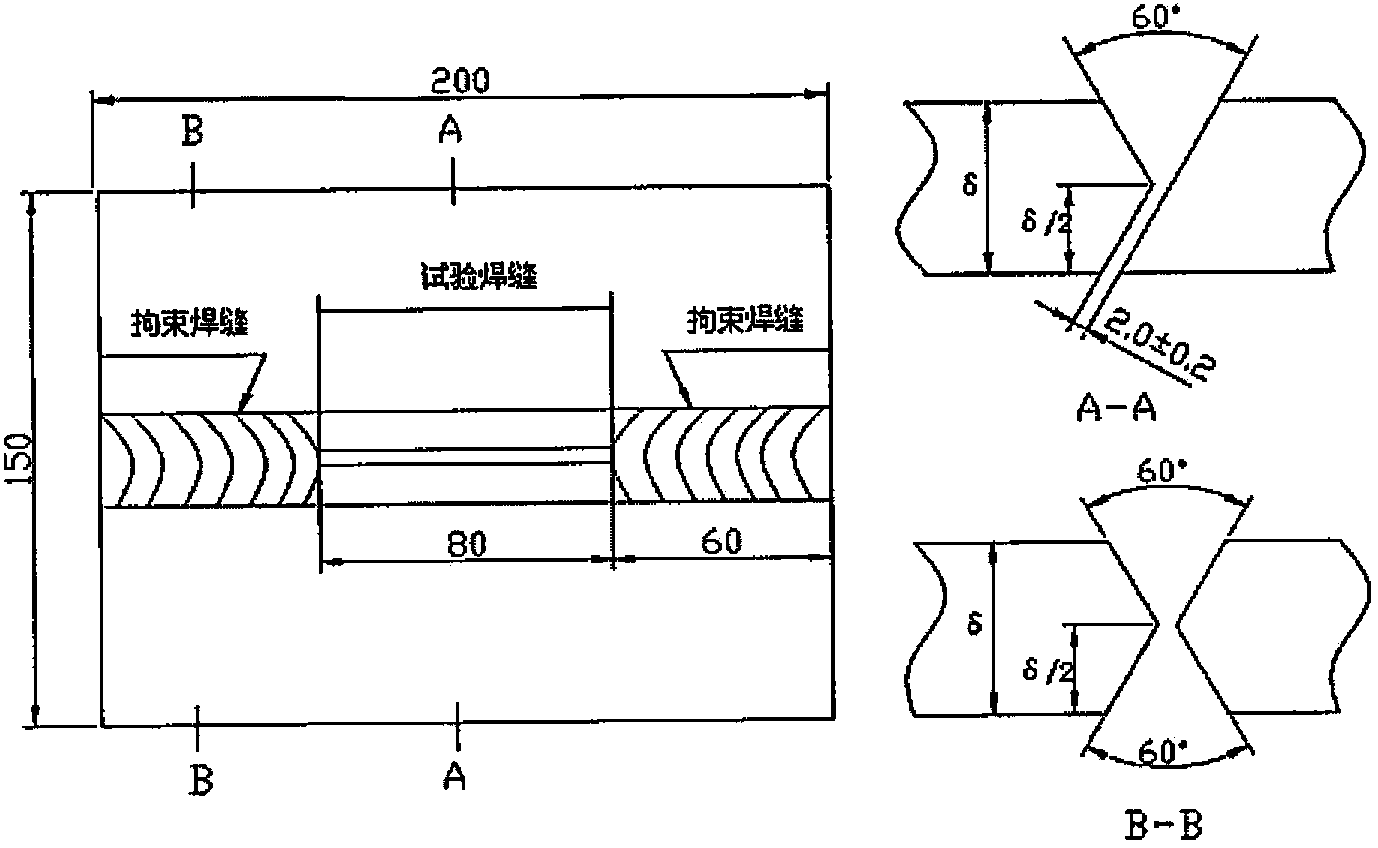

[0047] The smelting raw materials are manufactured according to the steps: smelting→casting→heating→rolling→cooling directly after rolling.

[0048] See Table 2 for the specific process parameters in Examples 1-7.

[0049]

[0050]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

Disclosed is an abrasion resistant steel plate, having the following chemical composition (weight%): C: 0.22 - 0.35%, Si: 0.10 - 0.40%, Mn: 0.60 - 1.35%, Rho <= 0.015%, S <= 0.010%, Nb: 0.010 - 0.040%, Al: 0.010-0.080%, B: 0.0006 - 0.0014%, Ti: 0.005-0.050%, Ca: 0.0010 - 0.0080wt.%, V <= 0.080%, Cr <= 0.60%, W <= 1.00wt.%, N <= 0.0080%, O <= 0.0060%, and H <= 0.0004%, with 0.025% <= Nb + Ti <= 0.080%, 0.030% <= Al + Ti <= 0.12%, and the balance being Fe and inevitable impurities. A process for manufacturing the abrasion resistant steel plate comprises steps such as smelting, casting, rolling and directly cooling after rolling. The abrasion resistant steel plate obtained with the above components and process has a high strength and hardness, good low temperature toughness, and an excellent machining performance, and is suitable for devices in engineering machinery and mining machinery susceptible to wear, such as a clamshell, a scraping transporter, etc.

Description

technical field [0001] The invention relates to wear-resistant steel, in particular to a low-alloy, ultra-high-strength, high-toughness wear-resistant steel plate and a manufacturing method thereof. Background technique [0002] Wear-resistant steel plates are widely used in mechanical products such as engineering, mining, agriculture, cement production, ports, electric power and metallurgy that require high strength and high wear resistance due to extremely harsh working conditions. Such as bulldozers, loaders, excavators, dump trucks and grabs, stackers and reclaimers, feeding bending structures, etc. [0003] In recent decades, the development and application of wear-resistant steel have developed rapidly. Generally, the carbon content is increased and an appropriate amount of trace elements are added, such as chromium, molybdenum, nickel, vanadium, tungsten, cobalt, boron and titanium, etc., to make full use of precipitation strengthening, Different strengthening method...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/14C21D8/02

CPCC22C38/14C21D8/02C22C38/002C22C38/12C22C38/04C21D8/0263C22C38/22C21D2211/008C22C38/26C22C38/06C21D8/0226C22C38/02C22C38/28C21D8/0205C22C38/001C22C38/32C22C38/00C22C38/24C21D1/60C21D6/002C21D6/005C21D6/008C21D9/46

Inventor 李红斌姚连登苗雨川

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com