Method for manufacturing high-heat-conductivity molybdenum-copper-nickel alloy

A technology of high thermal conductivity and nickel alloy, which is applied in the field of manufacturing high thermal conductivity molybdenum-copper-nickel alloy, can solve the problems of poor wettability of solder and poor heat dissipation ability, and achieve vacuum airtightness, which is beneficial to ensure working reliability and material dense and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method of making high thermal conductivity molybdenum-copper-nickel alloy includes:

[0029] 1) Mixing process: Weigh the mixed powder with a mass ratio of Mo powder: Cu powder: Ni powder = 80:10:10, and stir it on a centrifugal ball mill for 4 hours;

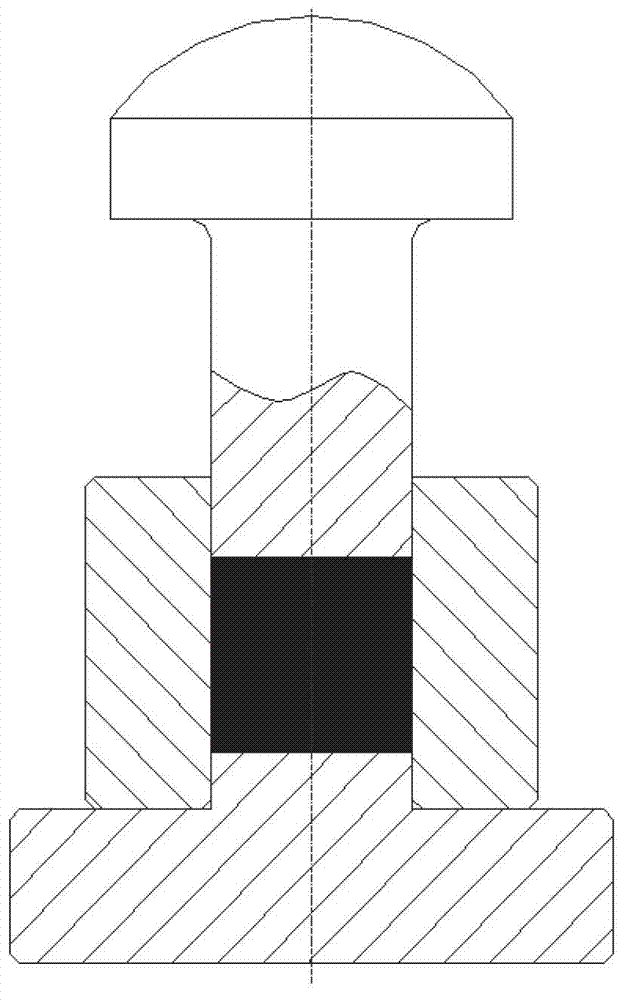

[0030] 2) Pressing process: Put the mixed powder evenly stirred into the pressing mold, set the pressure on the hydraulic press to 10-50t, and press the blank;

[0031] 3) Vacuum sintering process: Put the stamped blank into a vacuum furnace for high-temperature sintering. The temperature curve of high-temperature sintering is:

[0032] Heat up to (800±50)°C within 1 hour, keep warm for 0.5-1.5 hours;

[0033] Then heat up to (1250±10) °C within 1 hour and keep warm for 0.5-1.5 hours;

[0034] Then cool to room temperature within 2 hours;

[0035] 4) Copper immersion process: Melt the oxygen-free copper in a hydrogen atmosphere furnace, put the blank after vacuum sintering into the molten copper for immersion, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com