Preparation method capable of toughening and reinforcing polypropylene product

A polypropylene and product technology, applied in the field of plastic injection molding product processing, can solve many problems, and achieve the effect of simple components, easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

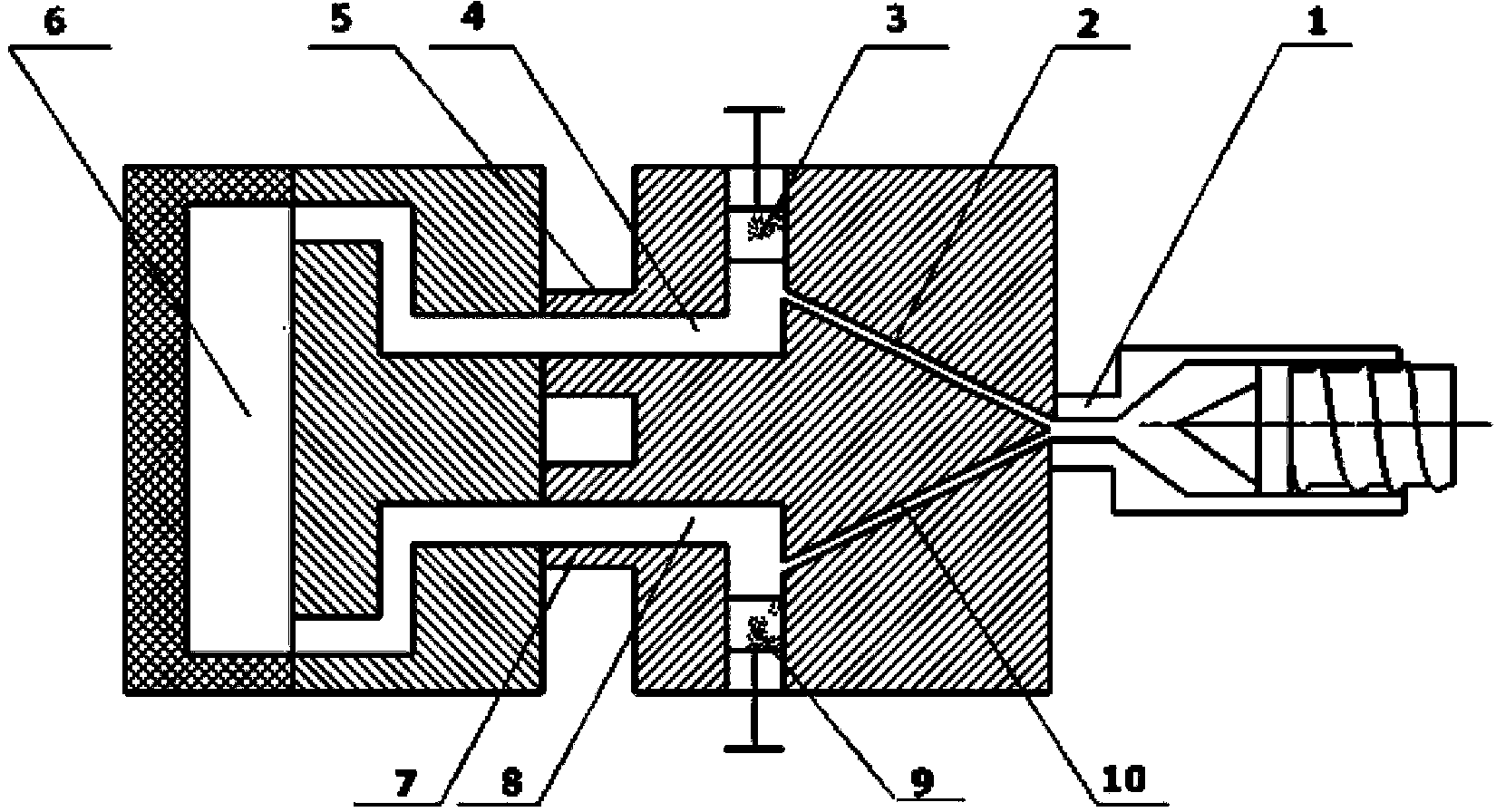

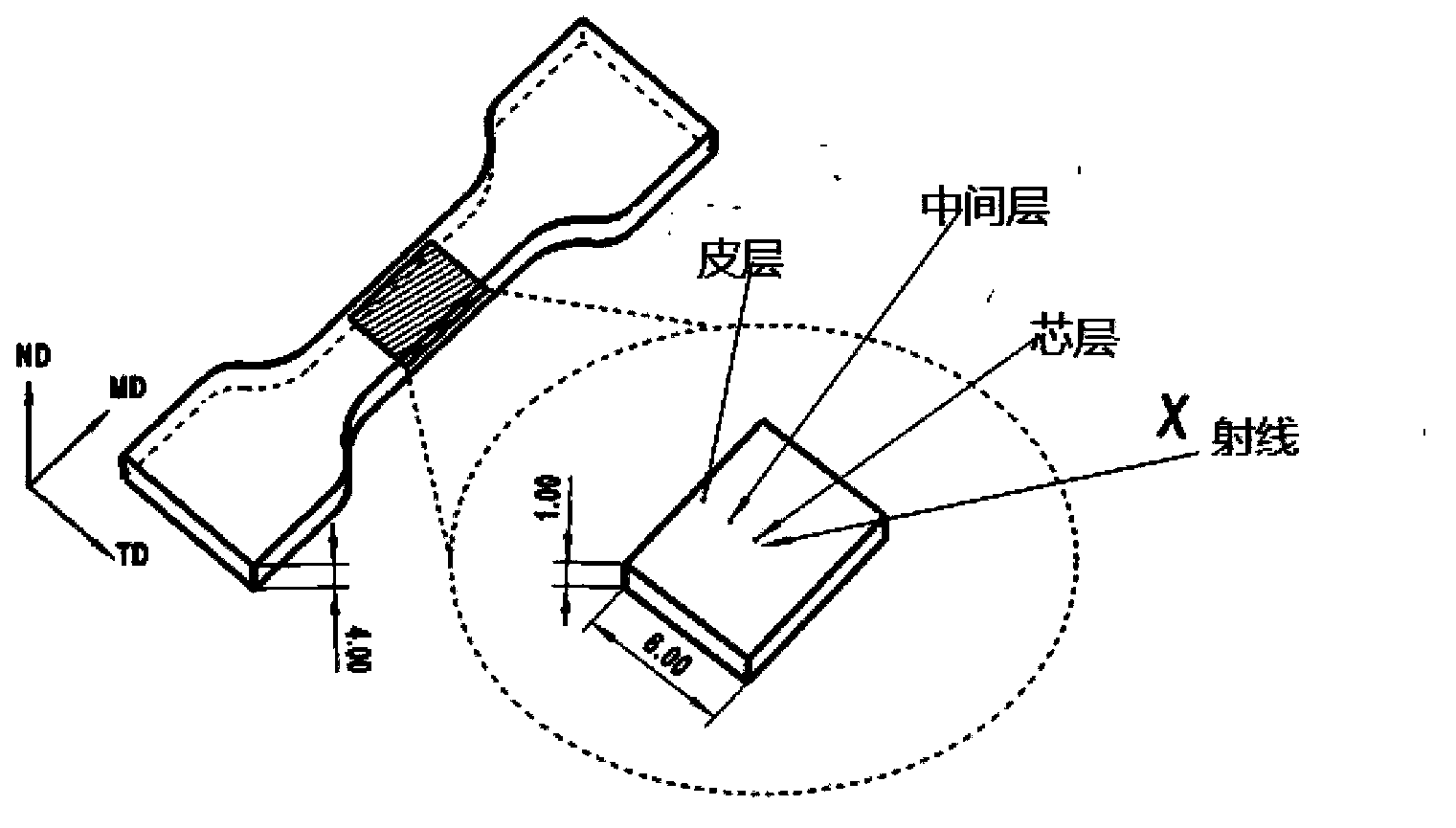

Method used

Image

Examples

Embodiment 1~4

[0023](1) Drying: Dry at 100° C. for 2 hours before use, so that the water content by weight is less than 0.01%. The trade name of β nucleating agent among the present invention is TMB-5, and it is a kind of nucleating agent (Shanxi Provincial Institute of Fine Chemical Industry) of substituted benzamides, and the grade of isotactic polypropylene used is T30s, and its melt index is 3g / 10min (230°C, 21.6N), weight average molecular weight is 39.9×104g / mol, molecular weight distribution is 4.6, (product of Dushanzi Petrochemical Company);

[0024] (2) Pre-mixing: the dried and cooled β-nucleating agent and isotactic polypropylene are stirred and mixed at room temperature according to the weight ratio until the β-nucleating agent is evenly distributed on the surface of the polypropylene. Its specific formula is shown in Table 1;

[0025] (3) Extrusion granulation: put the pre-mixed material in a twin-screw extruder to melt, mix and extrude it, using TSSJ 25 type, twin-screw extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com