PPS/BN composite material with high thermal conductivity and low friction coefficient and preparation method thereof

A technology of low friction coefficient and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of uneven sample performance, insufficient wear resistance, agglomeration, etc., and achieve easy implementation, low cost, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

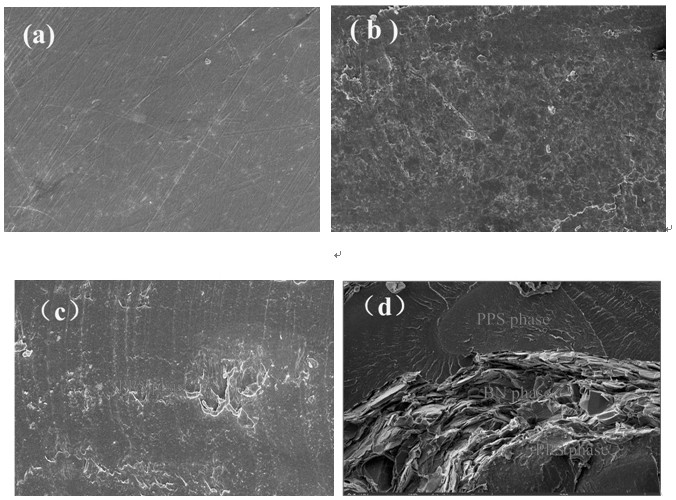

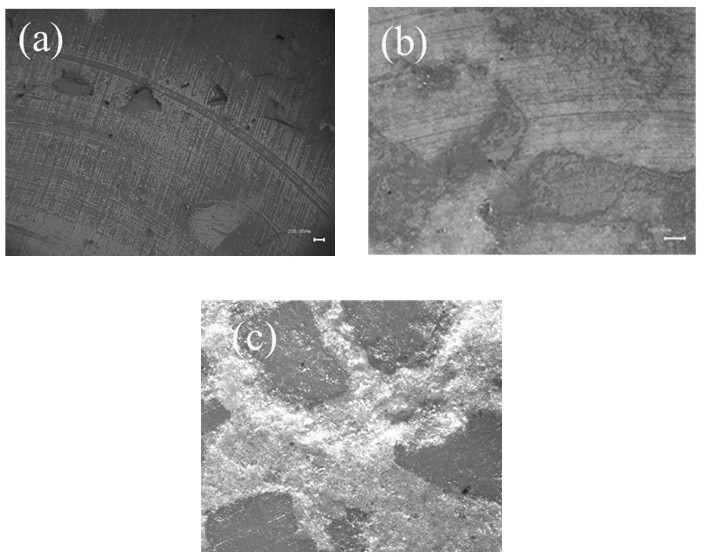

Image

Examples

Embodiment 1~12

[0027] (1) Mixing of PPS particles and BN: Add quantitative PPS particles with an average particle size of 1.39 mm (PPS-hb, Sichuan Deyang Special New Material Co., Ltd.) and 20 wt% absolute ethanol in the container at room temperature (AR, Guangdong Guanghua Technology Co., Ltd.), just wet the surface of PPS particles, according to the mass ratio of BN (BBN-30, Yaan Baitu High-tech Materials Co., Ltd. product) to PPS matrix: 15:85, 30: 70. PPS / BN composites with different ratios were obtained by adding BN microchips with an average size of 30 μm. In this process, the weighed BN needs to be added in batches, and each addition is fully stirred until the surface is evenly covered with a layer of BN, and there is no BN hanging on the inner wall of the container, and the mixture is mixed and used immediately.

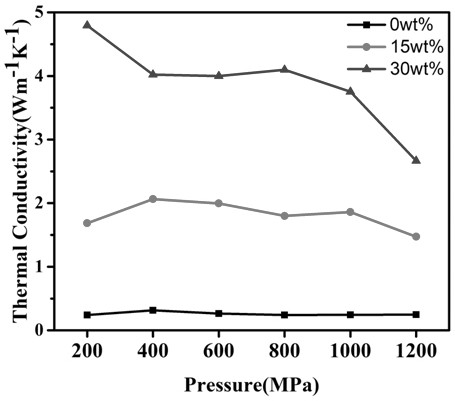

[0028] (2) Preparation of PPS / BN composite material by hot pressing method: hot pressing the mixed particles in step (1), the hot pressing process conditions are: after hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com