A high thermal conductivity polydopamine modified boron nitride/polyimide composite material and its preparation method

A technology of polydopamine and polyimide, applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve the effect of easy implementation, simple components, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~4 and comparative example 1~5

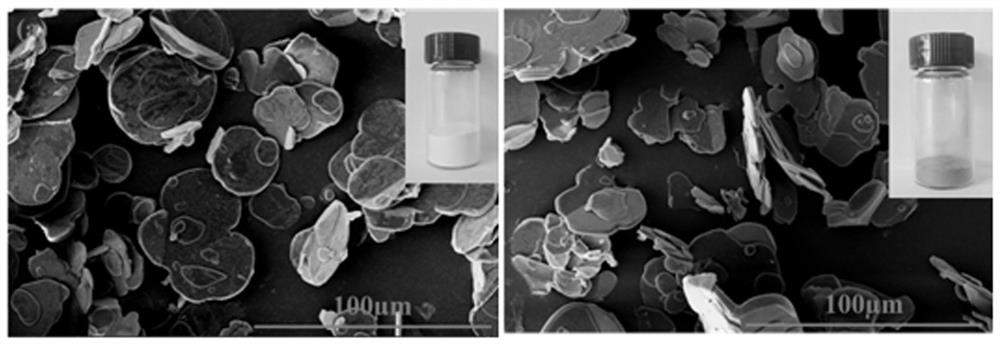

[0028] (1) Preparation of BN@PDA: Disperse 4 g of BN (BBN-30, product of Ya’an Baitu High-tech Materials Co., Ltd.) powder in 260 mL of deionized water, and then add 10 mmol (1.2114 g) of tris(hydroxymethyl) After aminomethane is completely dissolved, add 100 mL of absolute ethanol, 40 mL of hydrochloric acid (0.1 mol / L) in turn while stirring, and finally add 640 mg of dopamine hydrochloride, and stir magnetically for 6 h. The obtained BN@PDA dispersion was centrifuged and washed 4 times with ethanol / water mixture at 4000 rpm. After suction filtration, the BN@PDA modified filler was obtained after drying at 70 °C for 12 h;

[0029] (2) Preparation of PI solution: PI raw material (Ultem 1000, product of SABIC Innovative Plastics Co., Ltd.) was added to a certain amount of DMAc, and magnetically stirred at 120 °C for 10 h to obtain a PI solution with a solid content of 25 %;

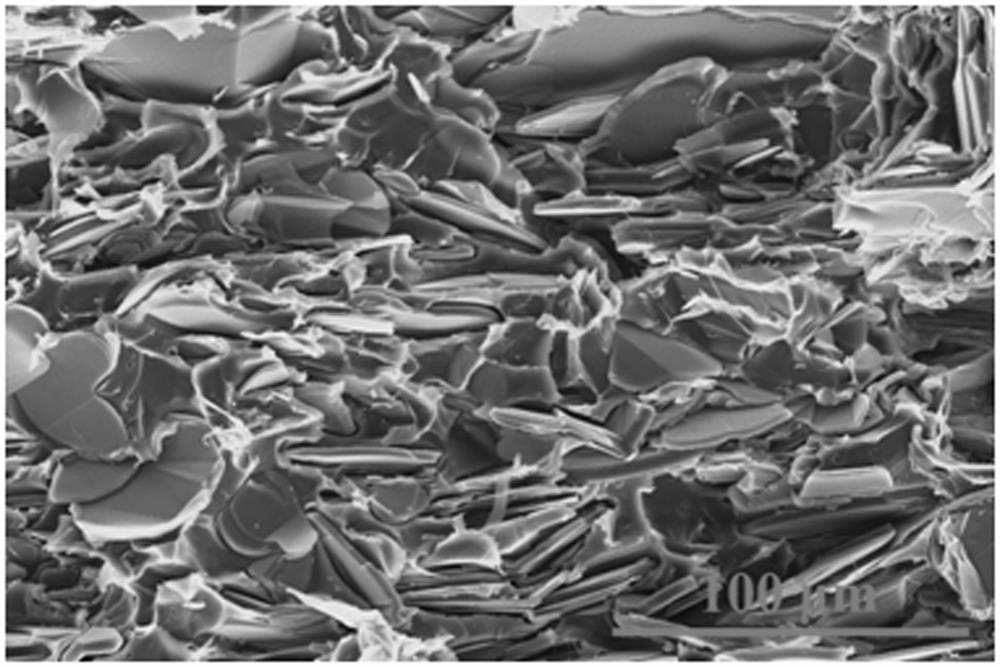

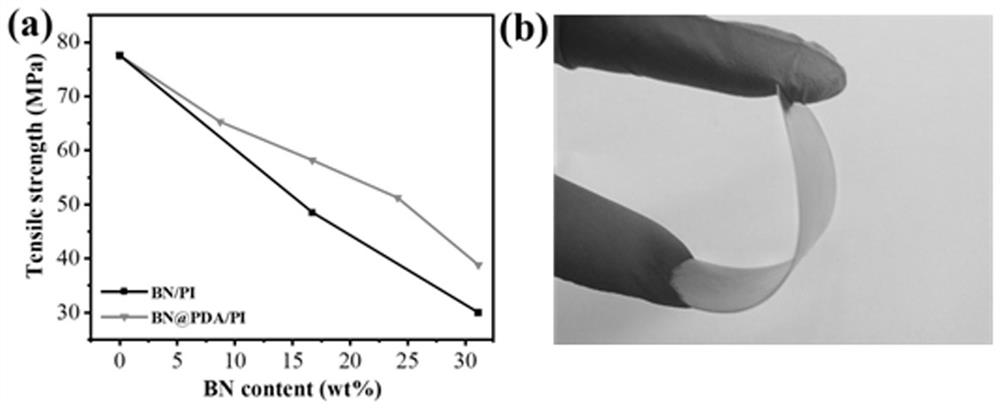

[0030] (3) Preparation of BN@PDA / PI / DMAC blend: Take a certain mass of BN@PDA (Example) or BN (Compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com