Synthesis method of ZSM-48 molecular sieve

A technology of ZSM-48 and synthesis method, which is applied in the field of molecular sieve synthesis technology, to achieve the effects of shortening the crystallization time, saving synthesis cost, and reducing synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

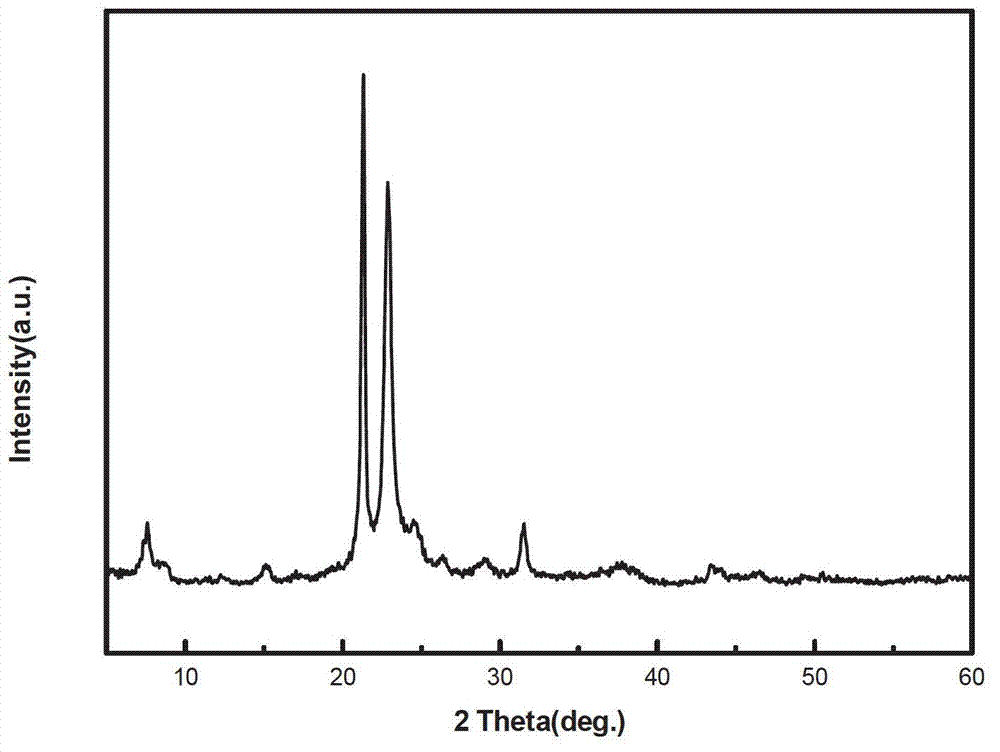

[0028] At initial gel ratio 600SiO 2 :Al 2 o 3 :18Na 2 O:240SDA:4000H 2 O Mix the metering raw materials in order, wherein the silicon source is fumed silica, the aluminum source is aluminum sulfate octadecadecahydrate, the alkali source is sodium hydroxide, and the template agent is hexamethylenediamine. Stir fully to form a gel, and then put it into a poly In the tetrafluoroethylene-lined autoclave, the crystallization temperature was set at 160°C, and the constant temperature crystallization was carried out for 72h. The solid product was separated, the mother liquor was recovered, the solid product was washed with deionized water until it was neutral, and dried in an air atmosphere at 85°C for 24 hours to obtain the original ZSM-48 molecular sieve powder, labeled as ZSM-48-1. The X-ray diffraction analysis results are as shown in the accompanying drawings, and its relative crystallinity is determined as 100%.

Embodiment 2

[0030] The mother liquor obtained in embodiment 1 is fully utilized, and the mother liquor is analyzed to obtain SiO 2 、Al 2 o 3 , SDA, Na 2 The corresponding content of O. The synthesis steps in Example 1 were repeated to obtain ZSM-48-2. The obtained mother liquor was then analyzed, and the synthesis steps were repeated to obtain ZSM-48-3. In this way, ZSM-48-4, ZSM-48-5, and ZSM-6 are obtained. The crystallinity of all obtained ZSM-48 series molecular sieves is shown in the table below. It can be found that the ZSM-48 molecular sieve synthesized after circulating the mother liquor for six times still maintains good crystallinity, and there is no impurity phase in the product.

[0031] Table 1 The relative crystallinity of ZSM-48 molecular sieve synthesized by recovery of mother liquor

[0032] sample

Embodiment 3

[0034] At initial gel ratio 400SiO 2 :60Na 2 O:400HDA:20000H 2 O Mix the metering raw materials in order, wherein the silicon source is fumed silica, the alkali source is potassium hydroxide, the template is pentamethylenediamine, and the aluminum source is not added, fully stirred into a gel, and then loaded into a polytetrafluoroethylene In the lined high-pressure reactor, the crystallization temperature was set at 160°C, and the constant temperature crystallization was carried out for 72h. The solid product was separated, the mother liquor was recovered, the solid product was washed with deionized water until neutral, and dried in an air atmosphere at 85°C for 24 hours to obtain the original ZSM-48 molecular sieve powder, whose relative crystallinity was 104%, and still maintained good crystallization The degree shows that high-quality pure silicon ZSM-48 molecular sieves can be synthesized under the selected conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com