Gas metal arc welding method and system

A melting gas and shielded welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as energy fluctuations, achieve the effects of suppressing fluctuations, stable welding process, and remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing description and specific embodiment, the present invention is described in further detail:

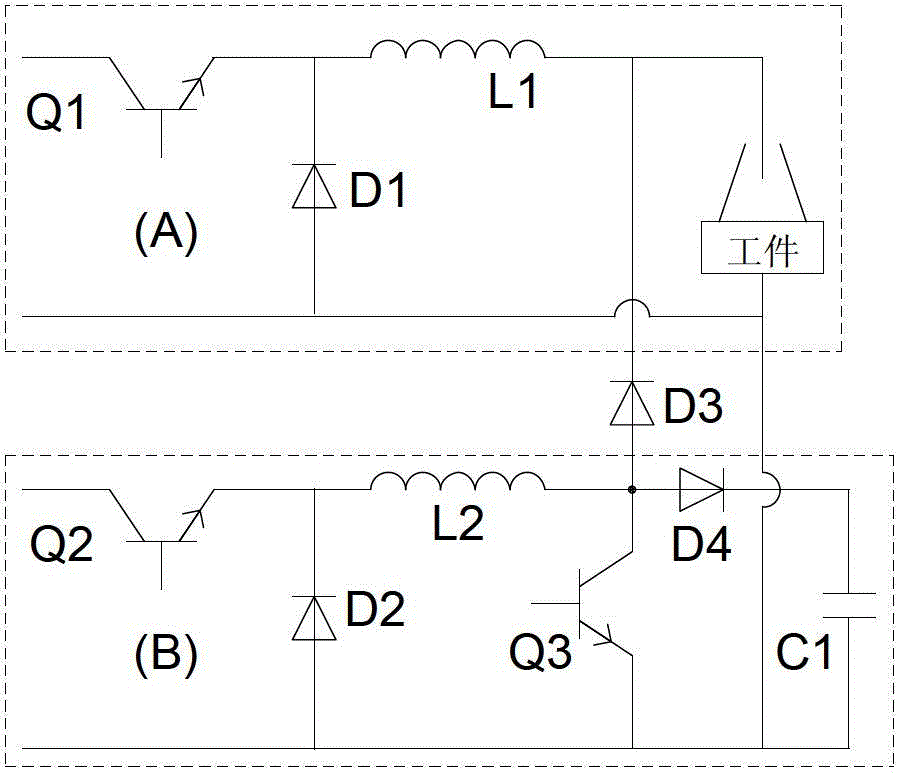

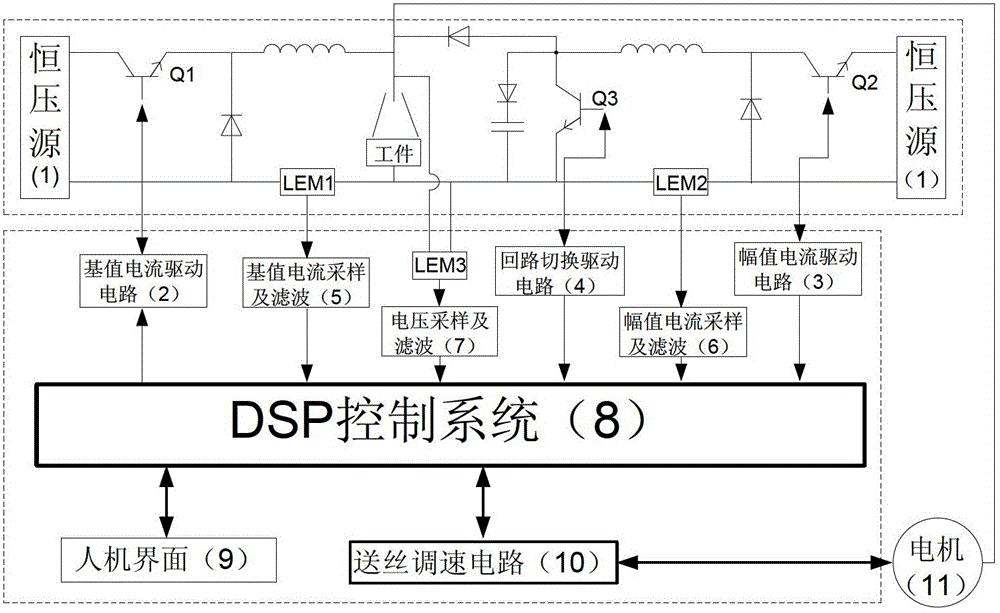

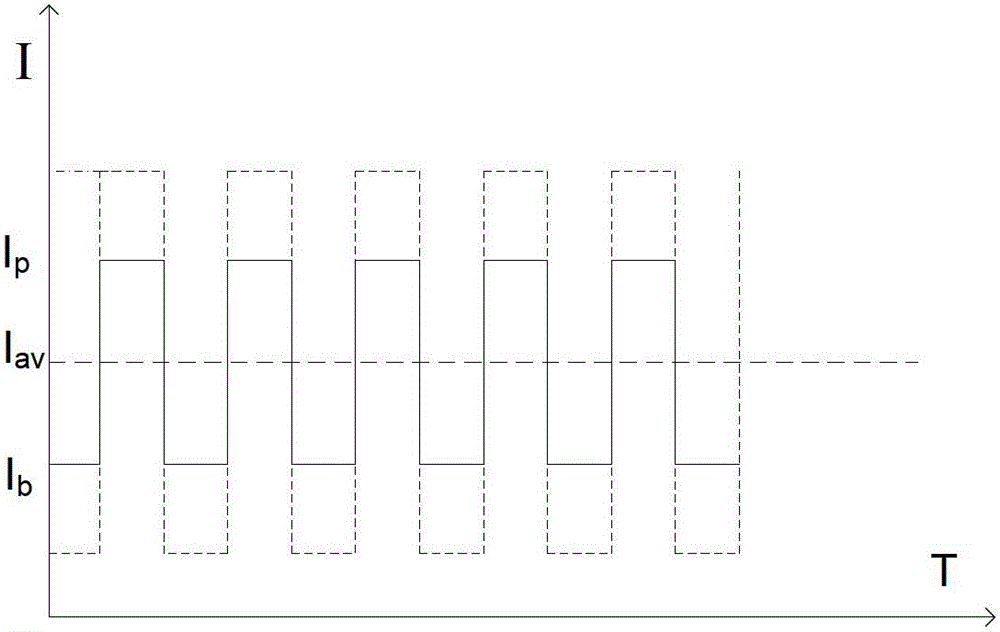

[0025] like figure 1 Shown is the schematic diagram of the main circuit of the present invention. BUCK circuit A includes switch tube Q1, inductor L1, and diode D1; BUCK circuit B includes switch tube Q2, inductor L2, and diode D2; when switch tube Q3 is turned on, BUCK circuit B forms a loop, and BUCK circuit A outputs a constant The current is added to the welding wire and the workpiece as the base value of the pulse current. When the switch tube Q3 is turned off, due to the large inductance value of the inductor L2, the current direction remains unchanged, the current of the BUCK circuit B is superimposed on the BUCK circuit A through the diode D3, and the currents of the two BUCK circuits are added Applied to the welding wire and the workpiece as the peak value of the pulse current. Because the switch between the base value a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com