Tunnel type microwave equipment suitable for sterilizing powdery material

A powdery material, tunnel-type technology, applied in the fields of application, food science, food preparation, etc., can solve the problems of affecting the sterilization effect, low production capacity, poor sterilization effect, etc., to achieve improved sterilization effect, outstanding effect, and non-toxic The effect of thermal sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

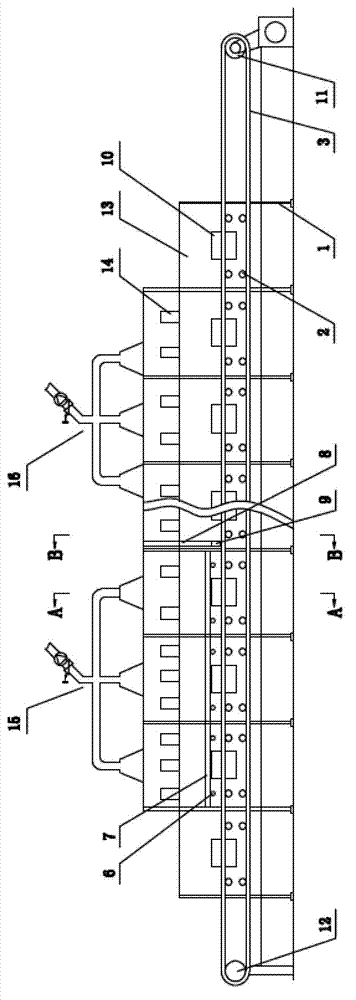

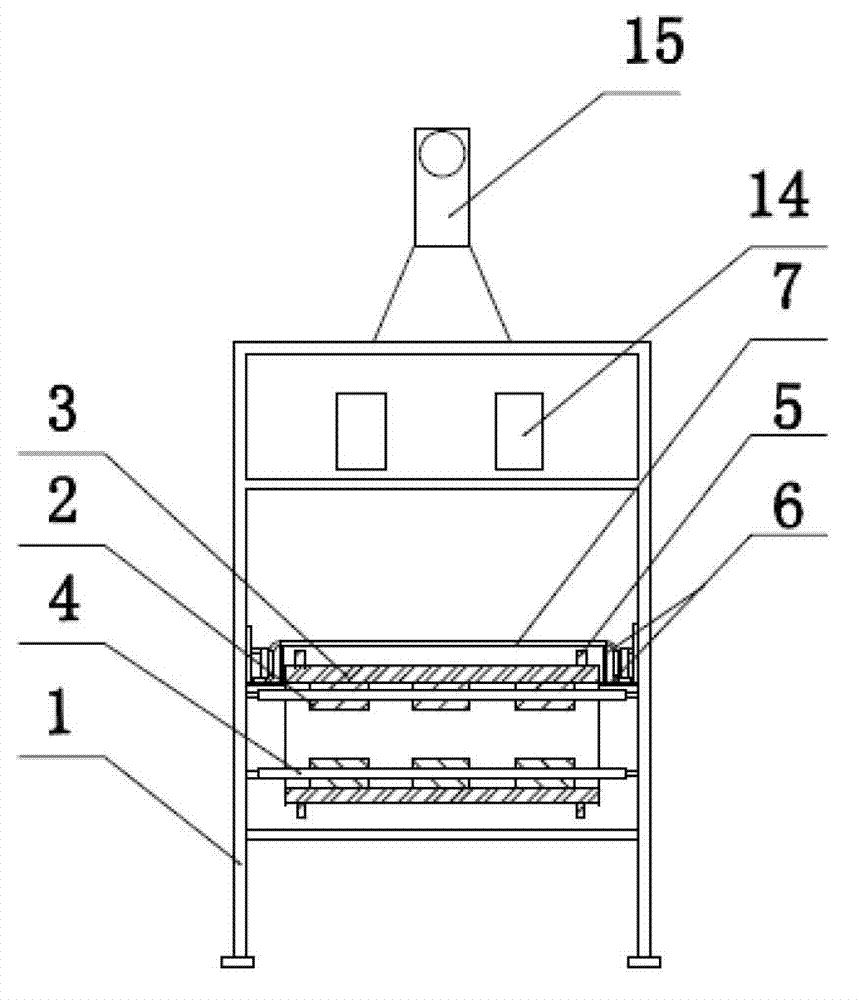

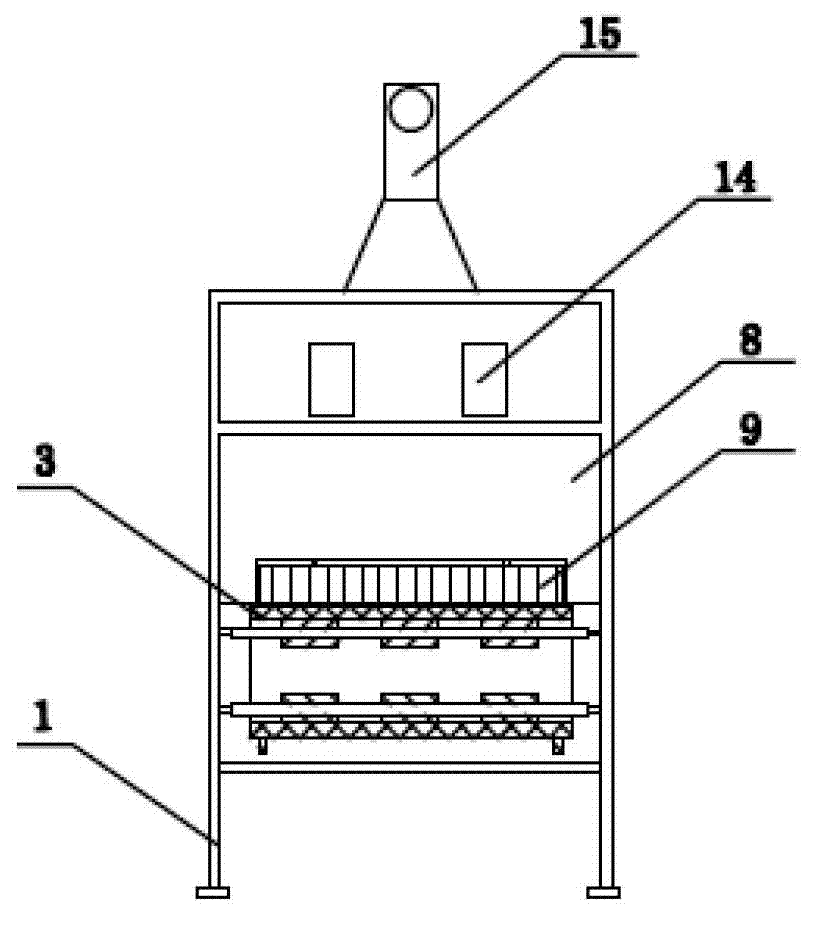

[0034] Such as Figure 1 to Figure 6 As shown, a tunnel-type microwave equipment suitable for sterilization of powdery materials includes a furnace body support 1, a furnace body 13, a conveying system, a microwave heating system, and an exhaust system. The inside of the furnace body 13 is provided with a microwave oven cavity. The conveying system includes a driving roller 11, a driven roller 12 and a conveying belt 3 running through the cavity of the microwave oven. The inner side of the conveying belt 3 is provided with an idler 2, and the idler 2 is installed on the On the furnace body 13 , a covering device is provided on the upper part of the conveyor belt 3 at the front section of the microwave oven cavity, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com