Composite anion-exchange membrane, its preparation and application

A composite anion and ion exchange technology, applied in the field of composite anion exchange membrane and its preparation, can solve the problems of decreased strength, difficult to control radiation dose, and high price of radiation equipment, and achieve the guarantee of electrical conductivity and swelling resistance, stable interface and mechanical properties. The effect of stability, simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

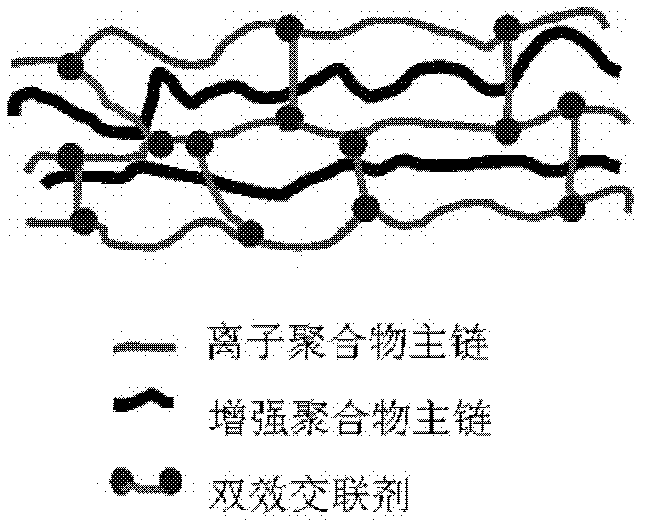

Method used

Image

Examples

Embodiment 1

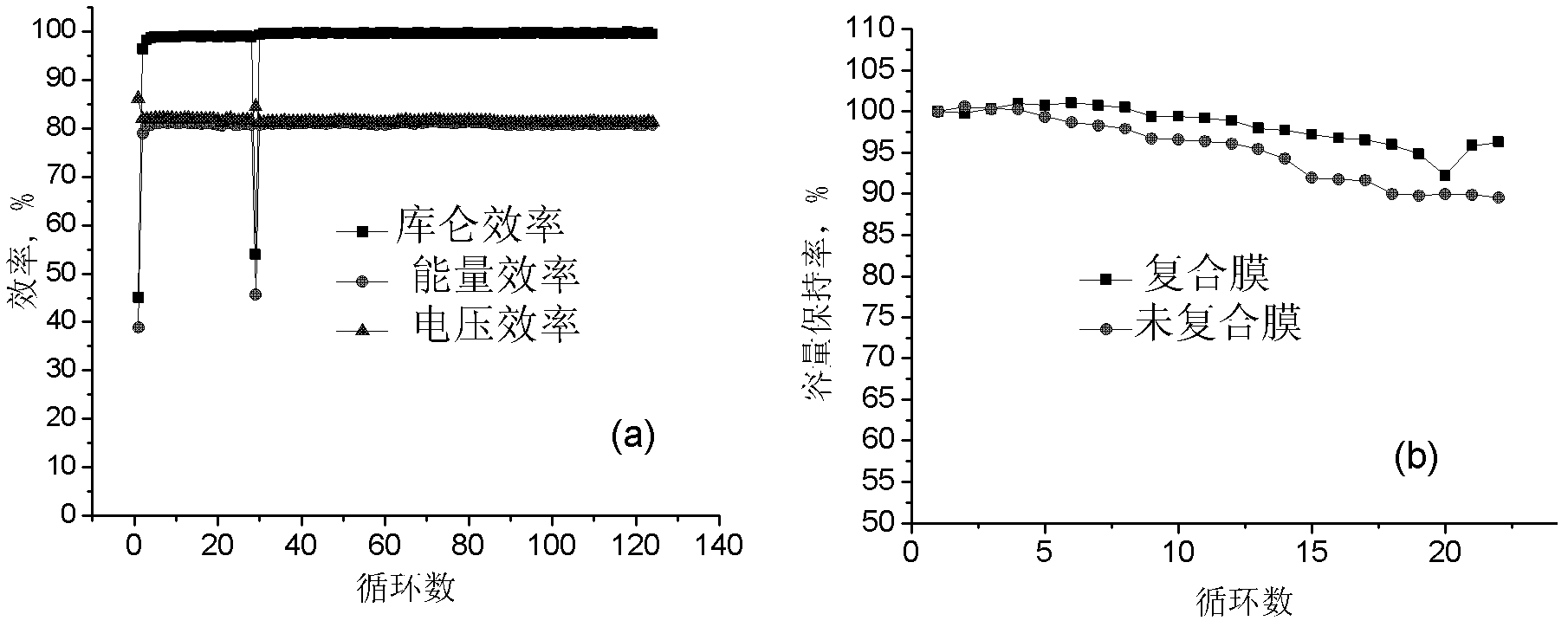

[0055] Dissolve 0.25 g of chloromethyl polysulfone (chloromethyl degree: 0.74), 0.05 g of PVDF in 5 ml of NMP, add 180 μL of a mixture of methylimidazole and aminopropylimidazole (the volume ratio of the two is 5:1), 30 ° C Stir under low temperature for 2 hours, cast a film (area 6×6cm2) on flat glass, dry overnight at 60°C, and dry at 80°C for 48 hours; the obtained film thickness is 60 microns, and the current Efficiency > 99%, energy efficiency 80-81%, the battery runs 130 cycles, the efficiency is very stable (attached figure 2 a). The capacity stability of the battery is better than that of the uncompounded polysulfone imidazole membrane (attached figure 2 b).

Embodiment 2

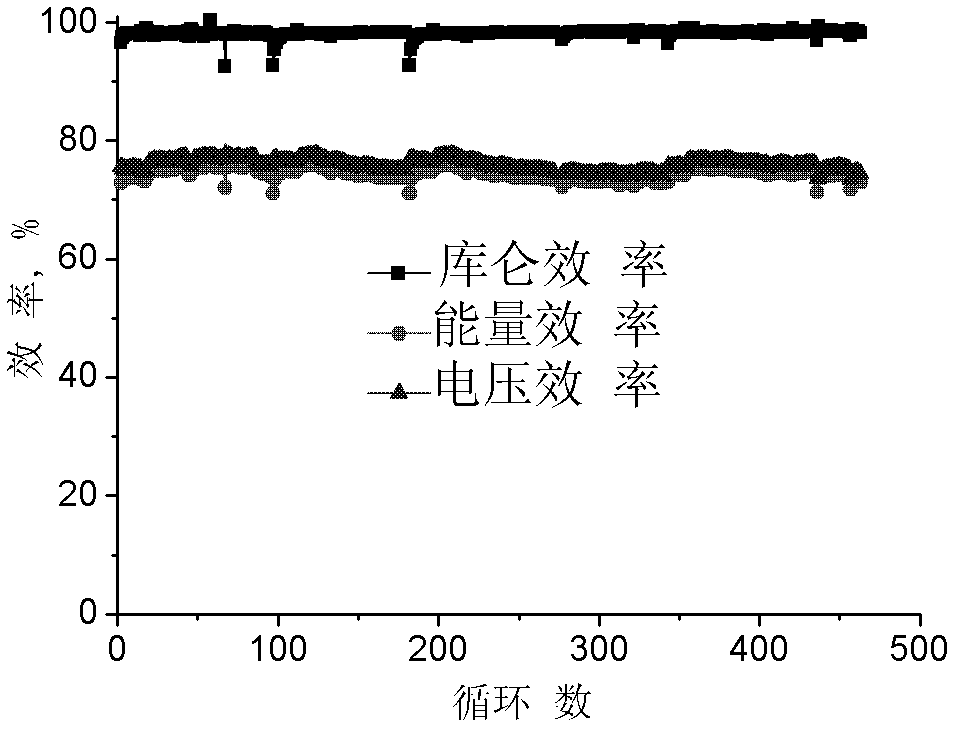

[0057] Dissolve 0.35 g of chloromethyl polysulfone (chloromethyl degree: 0.74), 0.07 g of PVDF in 7 ml of NMP, add 210 μL of a mixture of methylimidazole and aminopropylimidazole (the volume ratio of the two is 13:1), 30 ° C Stir for 2 hours, cast film on flat glass (area 12 × 5cm 2 ), dried overnight at 60°C, and dried at 80°C for 48 hours; the obtained membrane-assembled all-vanadium redox flow energy storage battery (VRB), charged and discharged at 80mAcm-2, operated continuously for 460 cycles, with an average Coulombic efficiency of 98.1%, and an average energy efficiency of 74.5, basically stable (attached image 3 ).

Embodiment 3

[0059] Dissolve 0.705 g of chloromethyl polysulfone (chloromethyl degree: 0.86), 0.175 g of PVDF in 15 ml of NMP, add 420 μL of a mixture of methylimidazole and aminopropylimidazole (the volume ratio of the two is 24:1), 30 ° C Stir for 2 hours, cast film on flat glass (area 14 × 12cm 2 ), dried overnight at 60°C, and dried at 80°C for 48 hours; the resulting film thickness is 60 microns, its VRB current efficiency is over 98%, and its energy efficiency is 80-82%. The battery runs for 220 cycles and its performance is basically stable (see attached Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com