NASICON-based H2S sensor using composite metallic oxide as sensitive electrode

A technology of sensitive electrodes and composite metals, applied in the direction of electrochemical variables of materials, etc., can solve the problem of large sensor size, achieve the effect of simple preparation process, good electrical conductivity and chemical stability, and promote practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

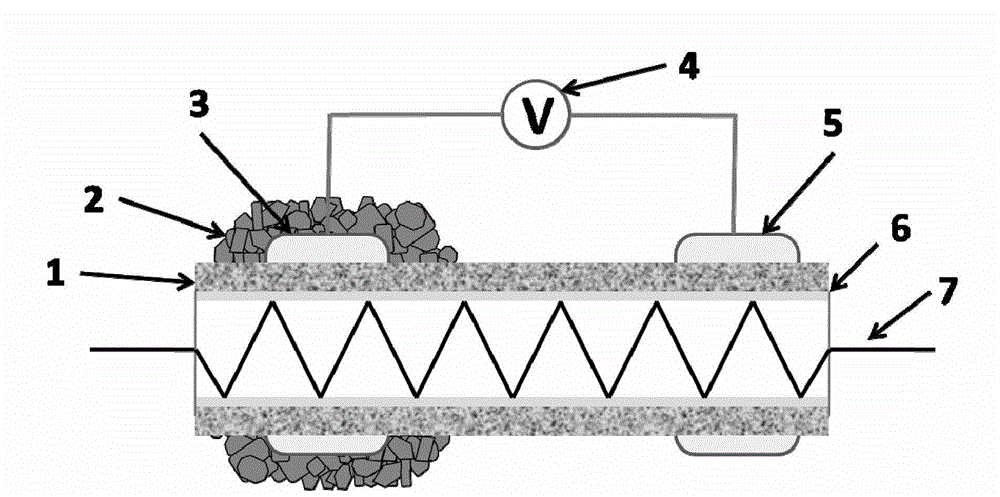

Image

Examples

Embodiment 1

[0054] CoCr 0.2 mn 1.8 o 4 As a sensitive electrode material, making H 2 S sensor, its fabrication process is

[0055] 1. With Cr(NO 3 ) 3 , Co(NO 3 ) 2 and Mn(NO 3 ) 3 Weigh the raw material according to the molar ratio of 0.2:1:1.8, dissolve it in 20ml of deionized water, add 15ml of concentrated nitric acid with a mass fraction of 65% and 80ml of ethylene glycol, react in a water bath at 80°C for 20 hours, and then heat to 100 ℃ for 3 hours to turn the sol into a gel, and then put it in a temperature condition of 160 ℃ for 20 hours to make it into a xerogel, and finally sintered in a muffle furnace at 800 ℃ for 8 hours to obtain CoCr 0.2 mn 1.8 o 4 Sensitive electrode materials;

[0056] 2. Preparation of NASICON powder by sol-gel method, coated on an insulating ceramic tube and sintered to form the ion-conducting layer of the sensor, with a thickness of 0.2 mm.

[0057] 3. Make gold electrodes. On the surface of the NASICON ion-conducting layer close to the e...

Embodiment 2

[0066] CoCr 0.6 mn 1.4 o 4 As a sensitive electrode material, making H 2 S sensor, its production process is based on Cr(NO 3 ) 3 , Co(NO 3 ) 2 and Mn(NO 3 ) 3 Prepare a solution for the raw material according to the molar ratio of 0.6:1:1.4. The specific preparation process is as described above to obtain CoCr 0.6 mn 1.4 o 4 . The fabrication process of the device is the same as above.

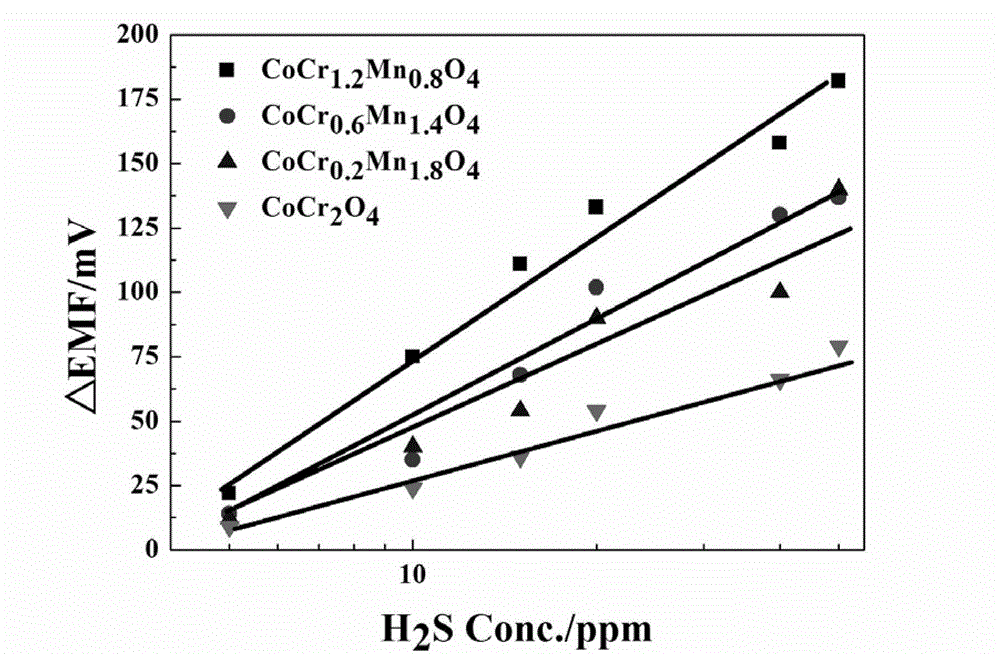

[0067] Table 2 lists the CoCr 2 o 4 and CoCr 0.6 mn 1.4 o 4 For sensitive material devices at different concentrations of H 2 The difference between the electromotive force in S atmosphere and the electromotive force in air (ΔEMF) varies with H 2 The change value of S concentration can be seen from the table by using CoCr 0.6 mn 1.4 o 4 As a sensitive electrode, the sensitivity of the sensor is further improved. And comparing Table 1 and Table 2, it can be seen that using CoCr 0.2 mn 1.8 o 4 The EMF change of the device is higher than that using CoCr 0.2 mn 1.8 o 4...

Embodiment 3

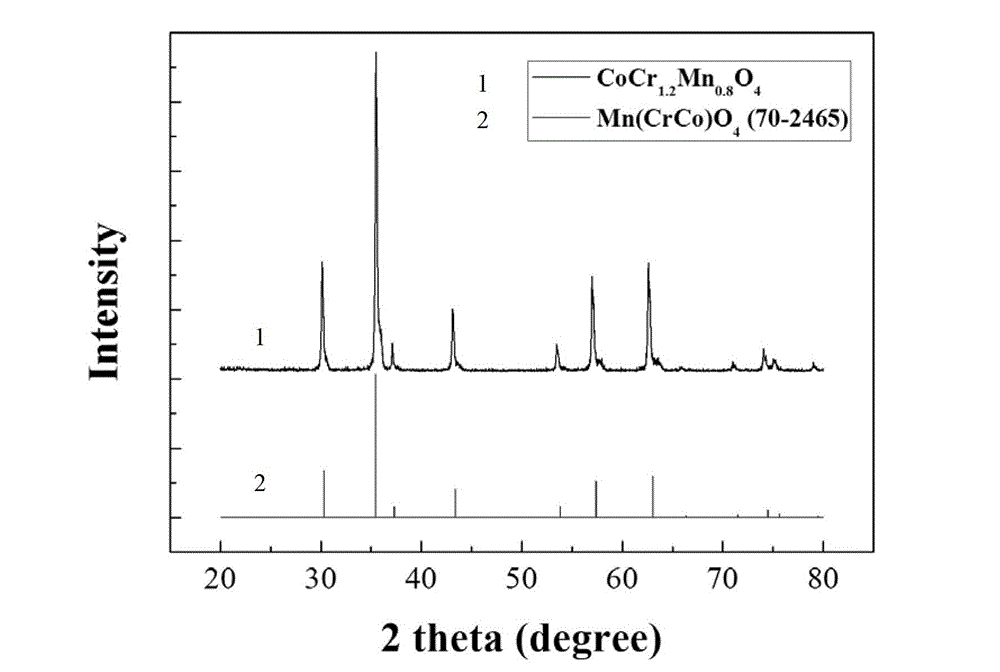

[0071] CoCr 1.2 mn 0.8 o 4 As a sensitive electrode material, making H 2 S sensor, its production process is based on Cr(NO 3 ) 3 , Co(NO 3 ) 2 and Mn(NO 3 ) 3 Prepare a solution for the raw material at a molar ratio of 1.2:1:0.8, and the specific preparation process is as described above. The fabrication process of the device is the same as above.

[0072] Table 2 lists the CoCr 2 o 4 and CoCr 0.8 mn 1.2 o 4 For sensitive material devices at different concentrations of H 2 The difference between the electromotive force in S atmosphere and the electromotive force in air (ΔEMF) varies with H 2 The change value of S concentration can be seen from the table by using CoCr 0.6 mn 1.4 o 4 As a sensitive electrode, the sensitivity of the sensor is further improved. And comparing Table 1, Table 2 and Table 3, it can be seen that the use of CoCr in the four devices 0.2 mn 1.8 o 4 The electromotive force change of the device as the sensitive electrode is more impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com