Strippable heat-proof antirust protective film coating and preparation method thereof

A protective film and coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as low glass transition temperature, poor environmental protection, and aesthetic impact, and achieve easy peeling, waterproof and anti-corrosion capabilities Better, Wider Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a peelable heat-resistant and anti-rust protective film coating, comprising the following steps:

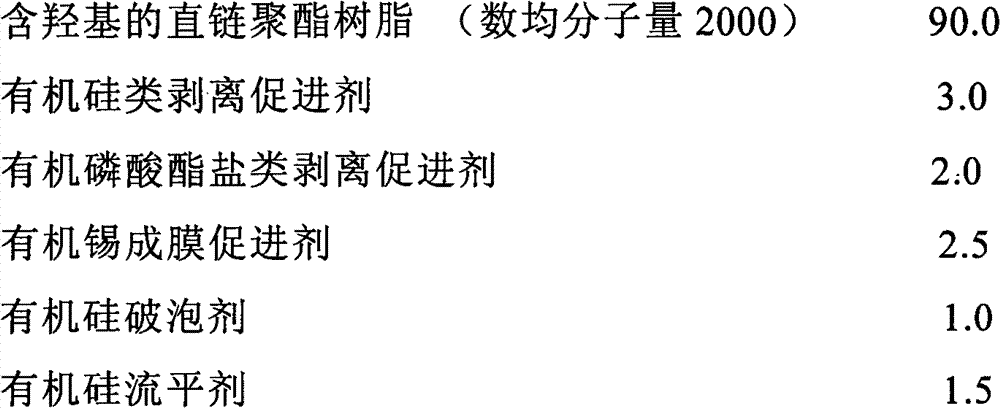

[0043] 1. Paint material:

[0044]

[0045] 2. Curing agent:

[0046] Isocyanate polymer 33.0

[0047] The preparation method is as follows process steps:

[0048] First put 90.0 parts of hydroxyl-containing linear polyester resin into the reaction kettle, and heat it to 30-60°C for stirring, keep stirring and put in 3.0 parts of organosilicon-based peeling accelerator, 2.0 parts of organic phosphate-based peeling accelerator, 2.5 parts of organotin film-forming accelerator, 1.0 parts of silicone foam breaker, 1.5 parts of silicone leveling agent, stir for 0.5 to 2.5 hours; after mixing evenly, stop the machine for more than 6 hours to ensure that the paint is mixed evenly. After defoaming, Cooperate with the curing agent to measure the solid content and peeling ability. After meeting the requirements, cool, weigh and pack; the curing agent is ...

Embodiment 2

[0050] A method for preparing a peelable heat-resistant and anti-rust protective film coating, comprising the following steps:

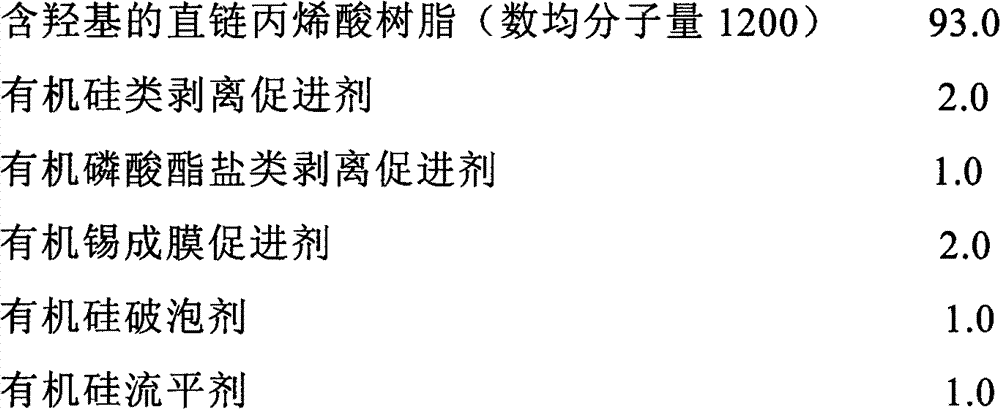

[0051] 1. Paint material:

[0052]

[0053] 2. Curing agent:

[0054] Isocyanate polymer 36.0

[0055] The preparation method is as follows process steps:

[0056] First put 93.0 parts of hydroxyl-containing linear acrylic resin into the reaction kettle, and heat it to 30-60°C for stirring, keep stirring and put in 2.0 parts of organosilicon-based peeling accelerator, 1.0 part of organic phosphate-based peeling accelerator, 2.0 parts 1 part of organotin film-forming accelerator, 1.0 part of silicone foam breaker, 1.0 part of silicone leveling agent, stir for 0.5 to 2.5 hours; after mixing evenly, stop the machine for more than 6 hours to ensure that the paint is evenly mixed. After defoaming, mix The curing agent measures the solid content and peeling ability. After reaching the requirements, it is cooled, weighed and packaged; the curing agent...

Embodiment 3

[0058] A method for preparing a peelable heat-resistant and anti-rust protective film coating, comprising the following steps:

[0059] 1. Paint material:

[0060]

[0061] 2. Curing agent:

[0062] Isocyanate polymer 30.0

[0063] The preparation method is as follows:

[0064] First put 91.0 parts of hydroxyl-containing linear polyester resin into the reaction kettle, and heat it to 30-60°C for stirring, keep stirring and put in 3.0 parts of organic silicon peeling accelerator, 3.0 parts of organotin film-forming accelerator, 1.5 1 part silicone foam breaker, 1.5 parts silicone leveling agent, stir for 0.5 to 2.5 hours; stop the machine for more than 6 hours after mixing evenly to ensure that the paint is evenly mixed. After defoaming, measure the solid content and peeling ability with the curing agent. After reaching the requirements, cool, weigh and pack; the curing agent is directly packed. When in use, the peelable heat-resistant and anti-rust protective film paint c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com