Electric contact and connection type COB (chip on board)-LED light source module

A COB-LED and light source module technology, applied in the field of LED lighting, can solve the problems of COB-LED light source components such as unfavorable heat dissipation, not compact enough structure, and many parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

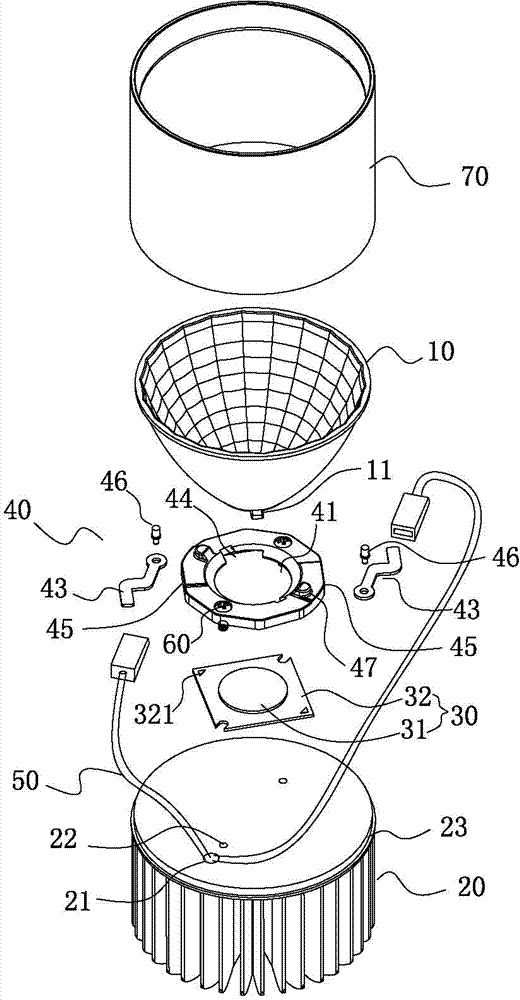

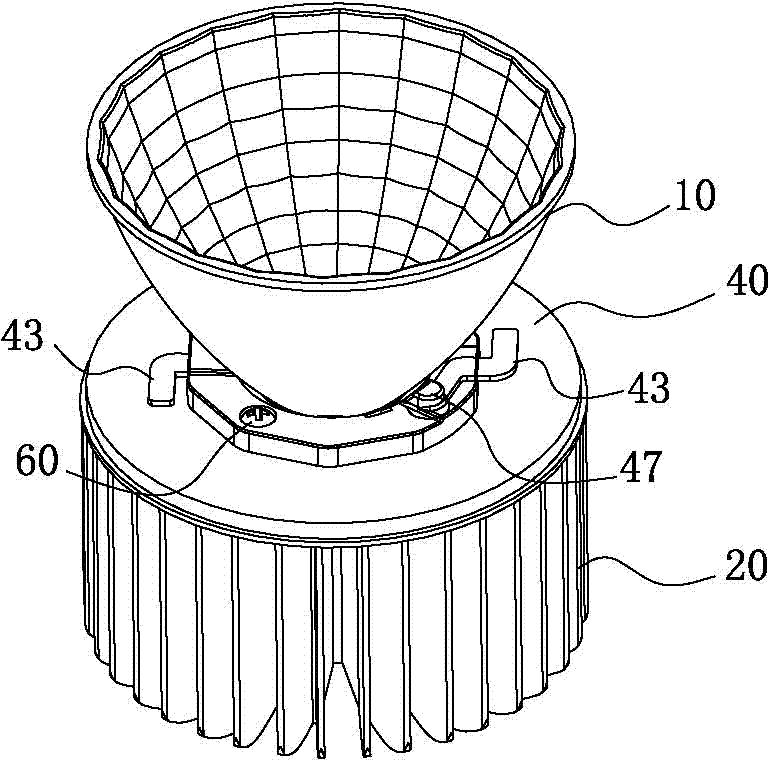

[0024] The following will be combined with Figure 1-6 An example for further details:

[0025] A welded COB-LED light source module in the embodiment includes a reflector 10, a radiator 20, a COB-LED light source assembly 30, an electrical interface bracket 40 and two single-core wires 50, and the COB-LED light source assembly 30 is made of LED chip 31 directly mounted on the PCB board 32 and then electrically connected and packaged as a whole through lead stitching;

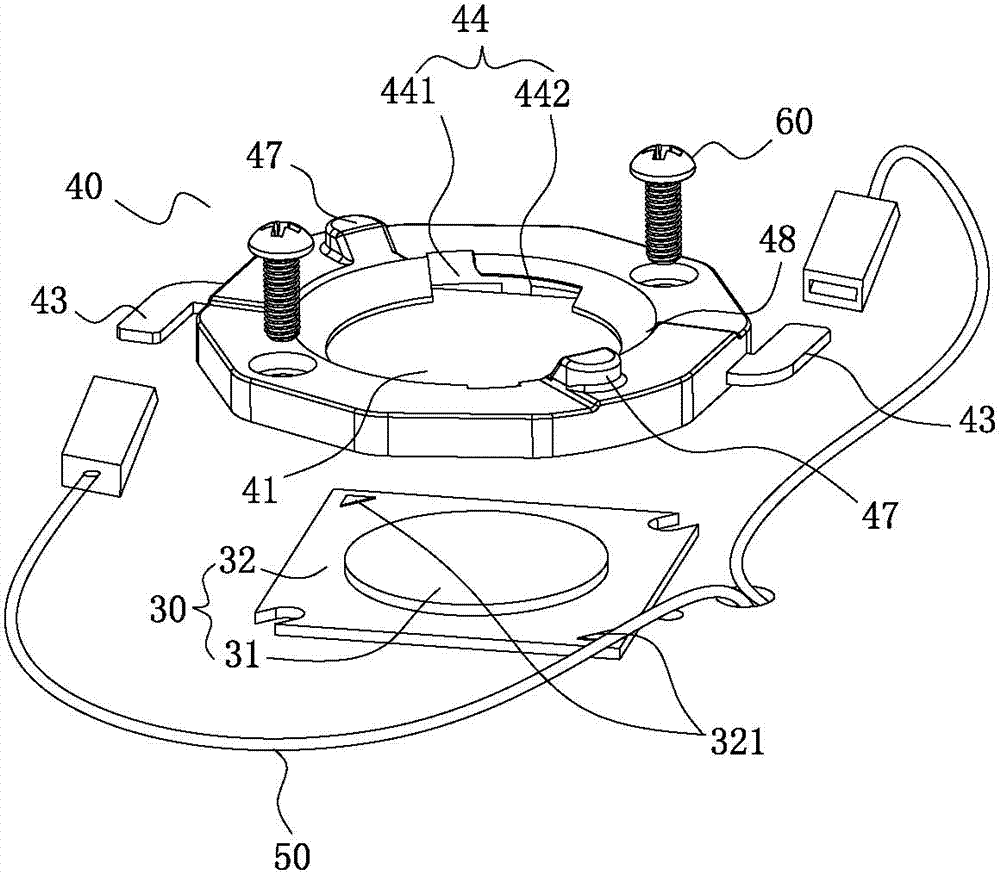

[0026] The middle part of the electrical interface bracket 40 has a through hole 41 corresponding to the LED chip, and the bottom surface of the electrical interface bracket 40 has a mounting groove 42 with the same size and shape as the PCB board 32. The inner wall of the through hole 41 is provided with a card slot 44, the card slot 44 is formed by connecting the insertion port 441 and the chute 442; the outer edge of the small opening of the reflector 10 has a buckle 11 corresponding to the card slot 44;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com