Self-air-entraining jet mechanism for axial fan/compressor

An axial flow fan and compressor technology, applied in the direction of machine/engine, jet propulsion device, etc., to achieve the effect of reducing power consumption, reducing flow loss, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

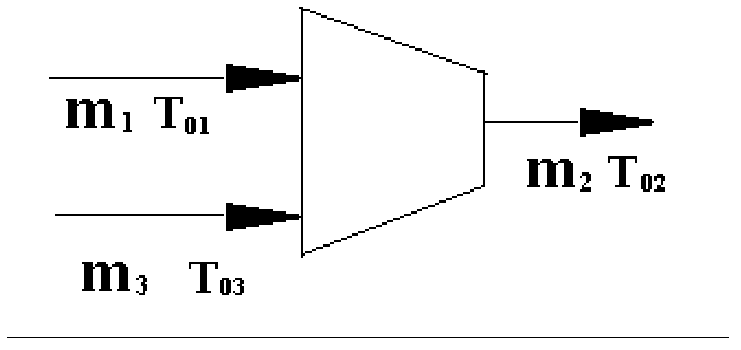

[0031] Under the premise of not considering the pipeline loss, from Figure 1a The shaft work of the compressor can be obtained from the external bleed air in:

[0032] Wc=m 1 c p (T 02 -T 01 )+m 3 c p (T 02 -T 03 ) (1)

[0033] The power consumption of external bleed air is:

[0034] Wp=m 3 c p (T 03 -T 01 ) (2)

[0035] The total power consumption is thus:

[0036] W=m 1 c p (T 02 -T 01 )+m 3 c p (T 02 -T 01 ) (3)

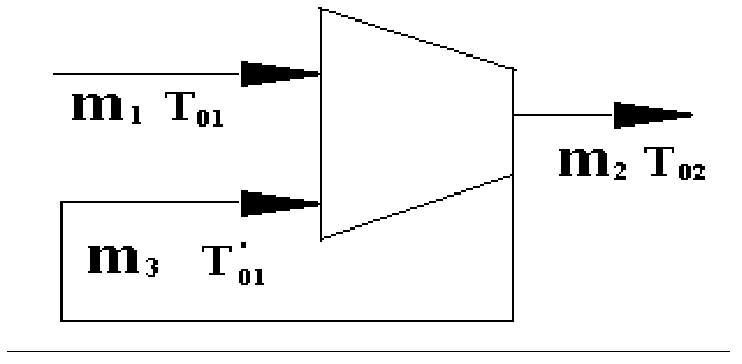

[0037] See Figure 1b , for self-entrained gas:

[0038]

[0039] therefore

[0040] Where Wc is the shaft work of the compressor, m 1 is the mass flow rate at the inlet of the compressor, m 2 is the mass flow rate at the inlet of the compressor, m 3 is the mass flow rate of bleed air, c p is specific heat capacity at constant pressure, T 01 is the mainstream inlet temperature of the compressor, T 02 is the main flow outlet temperature of the compressor, T 03 is the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com