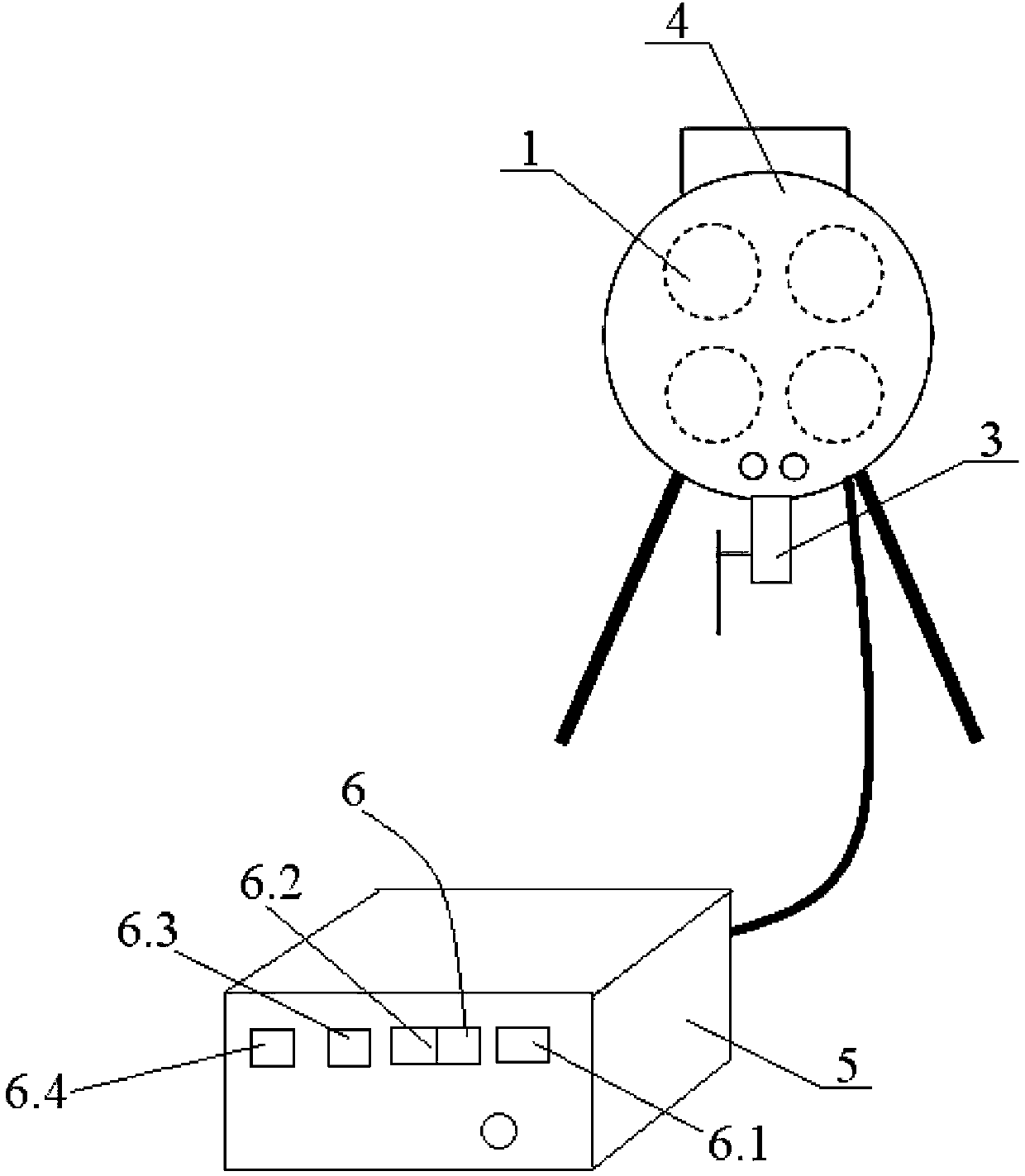

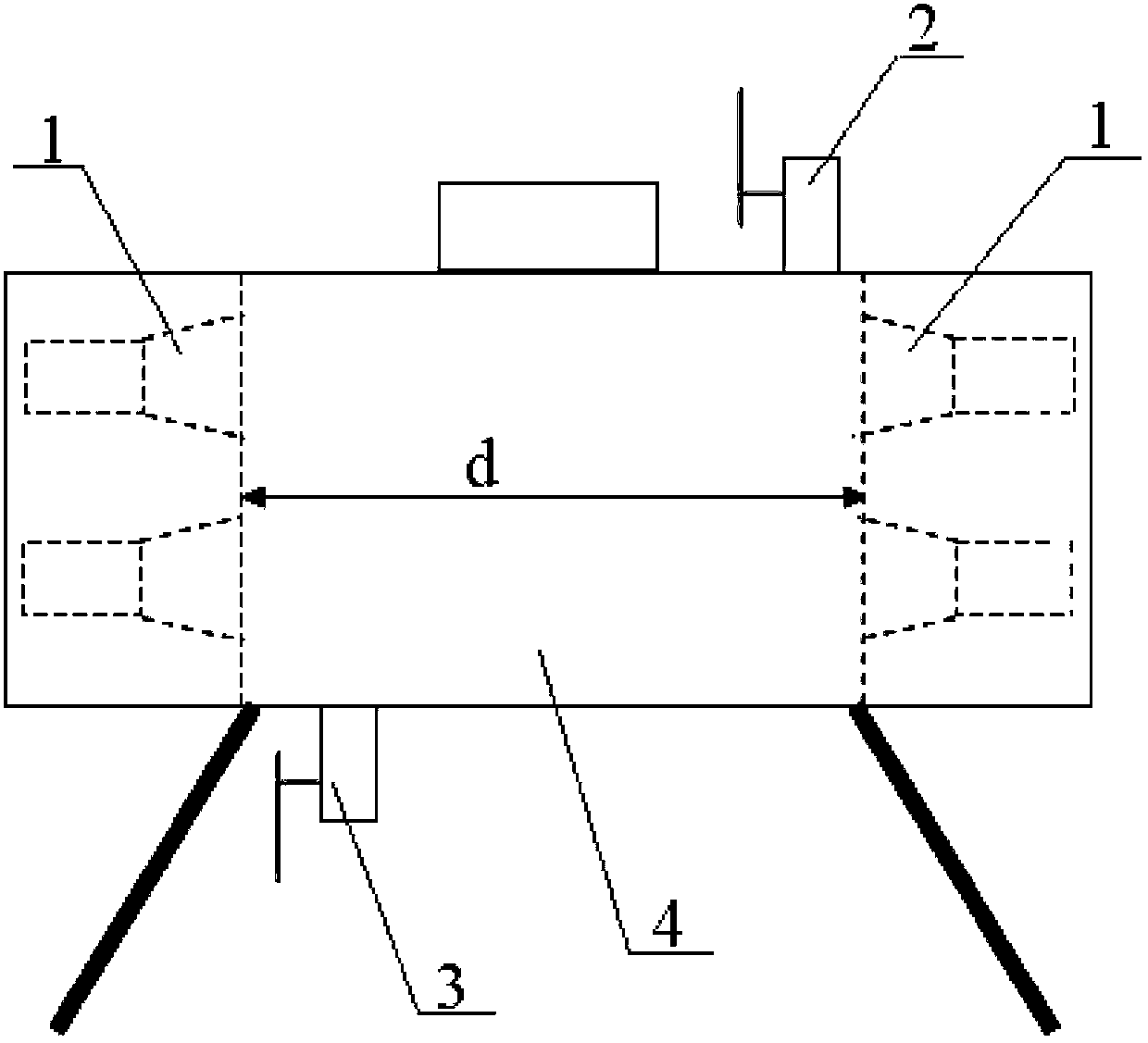

Separation method and device of polymer-containing oil sludge

A separation method and oil sludge accumulation technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of long treatment time, long irradiation time, complicated treatment process, etc., and achieve radiation Concentrated energy, reduced adhesion, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

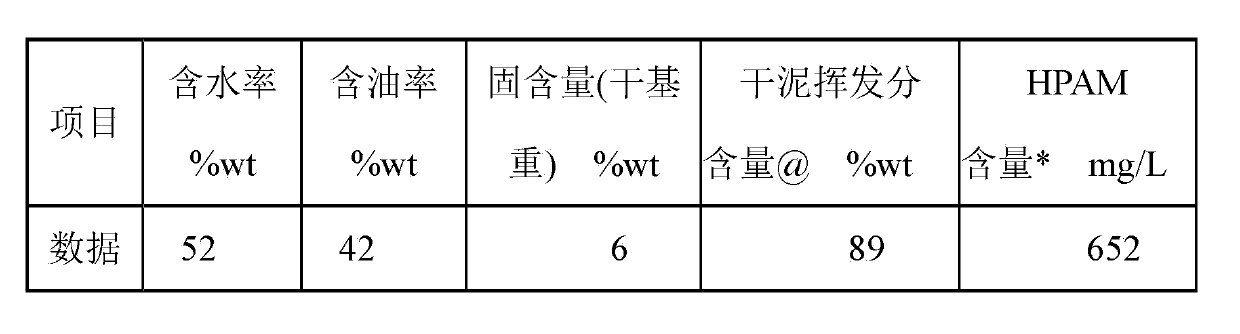

Embodiment 1

[0040] 1) Ultrasonic gel breaking of oily sludge: mix water and oily sludge at 90°C, the mass ratio of water to oily sludge is 1:1, then add potassium persulfate solution to the mixture, and over Potassium sulfate is 0.1% of the quality of the raw material containing poly-oil sludge, after mixing evenly, carry out ultrasonic treatment for 0.2min;

[0041] 2) Ultrasonic cleaning: Add alkylphenol polyoxyethylene ether solution and SP169 solution to the above-mentioned mixture of sludge containing oil after ultrasonic gel breaking. 0.03% of the mass of the raw material of poly oil sludge, after mixing evenly, carry out ultrasonic treatment at 90°C for 0.2min; wherein, the alkyl chain of the added alkylphenol polyoxyethylene ether is C 8 The alkyl group, the addition number of ethylene oxide is 5;

[0042]3) Static separation: The above ultrasonically cleaned mixture was left to settle at 90°C for 10 minutes, the upper layer was the separated crude oil, the lower layer was the se...

Embodiment 2

[0045] 1) Ultrasonic gel breaking of oily sludge: mix water and oily sludge at 80°C, the mass ratio of water to oily sludge is 2:1, then add hydrogen peroxide to the mixture, hydrogen peroxide contains H 2 o 2 2% of the mass of the raw material containing poly-oil sludge, after mixing evenly, perform ultrasonic treatment for 0.2min;

[0046] 2) Ultrasonic cleaning: Add alkylphenol polyoxyethylene ether solution and PFA-8311 solution to the above-mentioned mixture containing oil sludge after ultrasonic gel breaking, the alkylphenol polyoxyethylene ether solution is 0.03% of the mass of oil sludge containing raw material, PFA-8311 is 0.005% of the mass of the raw material containing poly oil sludge. After mixing evenly, ultrasonic treatment is carried out at 80°C for 3 minutes; the alkyl chain of the added alkylphenol polyoxyethylene ether is C 12 The alkyl group, the addition number of ethylene oxide is 10;

[0047] 3) Static separation: The above ultrasonically cleaned mixtu...

Embodiment 3

[0050] 1) Ultrasonic gel breaking of oily sludge: mix water and oily sludge at 60°C, the mass ratio of water to oily sludge is 5:1, then add sodium persulfate solution to the mixture, and overheat in the sodium persulfate solution Sodium sulfate is 0.4% of the quality of the raw material containing poly-oil sludge, after mixing evenly, carry out ultrasonic treatment for 5 minutes;

[0051] 2) Ultrasonic cleaning: Add alkylphenol polyoxyethylene ether solution and BP-2040 solution to the above-mentioned mixture of oily sludge after ultrasonic gel breaking. The amount of -2040 is 0.02% of the mass of the raw material containing poly oil sludge. After mixing evenly, ultrasonic treatment is carried out at 60°C for 0.5min; wherein, the alkyl chain of the added alkylphenol polyoxyethylene ether is C 9 The alkyl group, the addition number of ethylene oxide is 6;

[0052] 3) Static separation: the above ultrasonically cleaned mixture was left to settle at 60°C for 40 minutes, the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com