Automatic welding experiment system for simulating medium pressure liquid or gaseous environment

A technology of automatic welding and gas environment, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low automation, high experiment cost, poor applicability, etc., achieve high automation, good applicability, and reduce experiment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

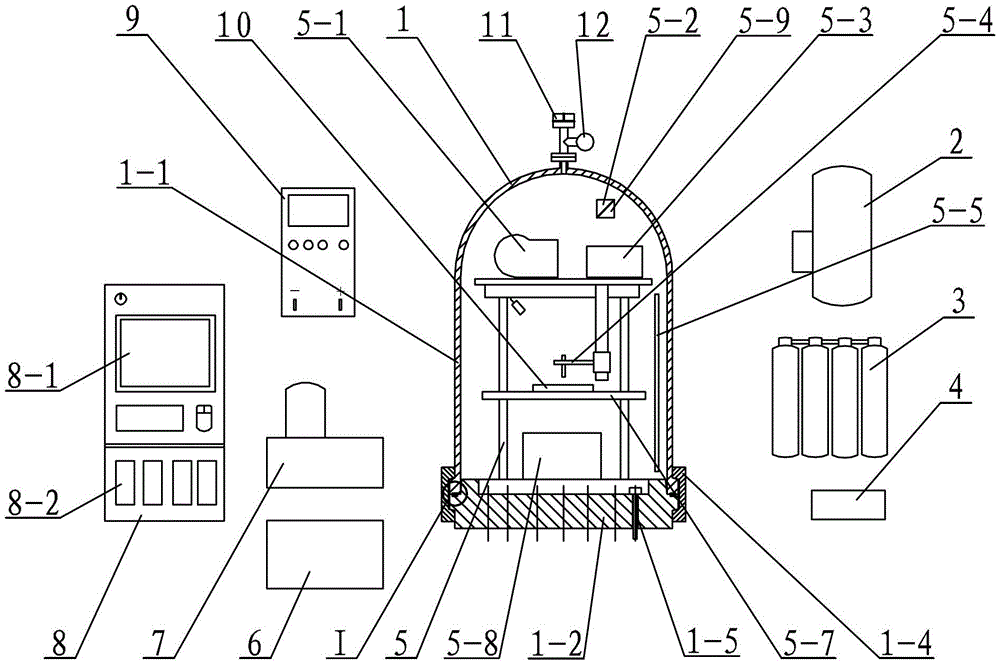

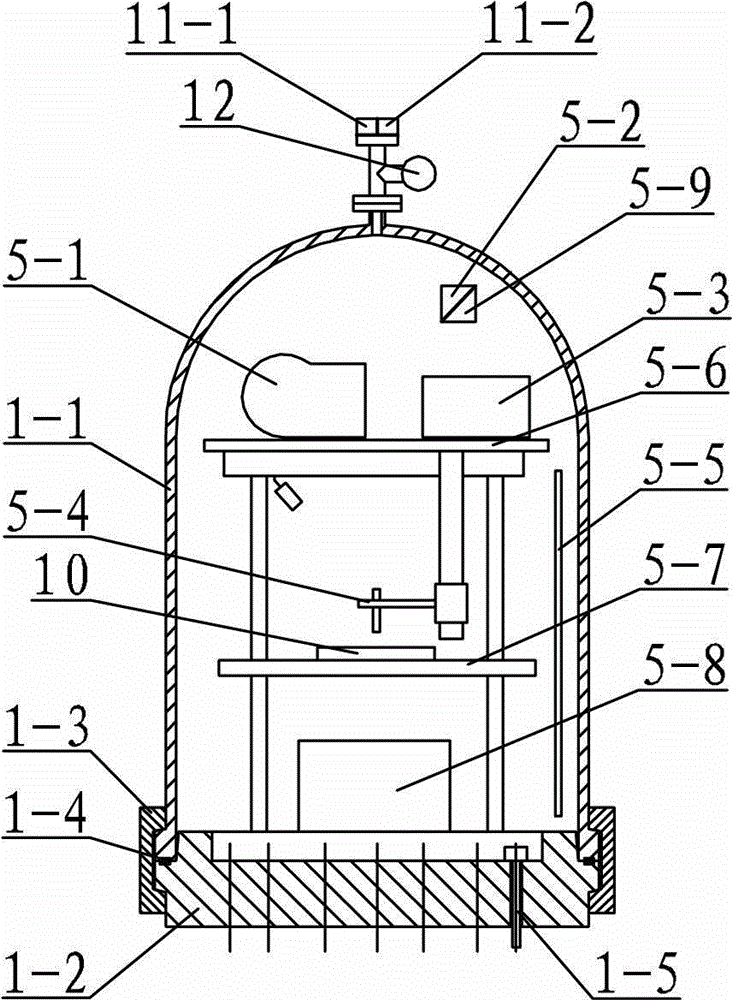

[0014] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes a medium pressure environment simulation cabin 1, a gas recovery device 2, a gas cylinder bundle 3, a vacuum pump 4, an experimental equipment 5 in the cabin, a cooling water circulation pump 6, a hydraulic pump station 7, a control cabinet 8 and a welding Power supply 9, safety valve 11 and pressure gauge 10, medium pressure environment simulation cabin 1 includes cabin body 1-1, bilge 1-2, annular sealing ring 1-3, two clamp devices 1-4 and several cabin penetrations Connectors 1-5, several tank penetration connectors 1-5 are evenly arranged in the end surface of the bilge 1-2, the cabin body 1-1 is set above the bilge 1-2, and the annular sealing ring 1-3 is set in the tank Between the body 1-1 and the bilge 1-2, two hoop devices 1-4 are arranged symmetrically at the junction of the cabin body 1-1 and the bilge 1-2, and the two hoops 1-4 are fastened into...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination Figure 4 Describe this embodiment, each clamp device 1-4 of this embodiment is composed of semicircular clamp 1-4-1, clamp opening and closing cylinder 1-4-2, clamp support wheel 1-4-3, cylinder connector 1-4-4 and the oil cylinder bracket 1-4-5, the curved inner surface of the semicircular clamp 1-4-1 is provided with a trapezoidal groove 1-4-1-1 along the length direction, and the clamp opening and closing cylinder 1- The fixed end of 4-2 is hinged with the cylinder bracket 1-4-5, the piston end of the clamp opening and closing cylinder 1-4-2 is hinged with the cylinder connector 1-4-4, and the cylinder connector 1-4-4 is connected with the semicircle The arc-shaped outer surface of the clamp 1-4-1 is fixedly connected, and the clamp support wheel 1-4-3 is installed on the lower end surface of the semicircular clamp 1-4-1. During use, the oil cylinder support 1-4-5 is fixedly connected with the upper end surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com