Accident swing groove device

A kind of accident and tank body technology, which is applied in the field of accident slotting device, can solve the problems of potential safety hazards, waste of resources, difficulties in online repair or replacement, etc., and achieve the reduction of molten steel splash, increase of safety factor, and simple and convenient disassembly and connection steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

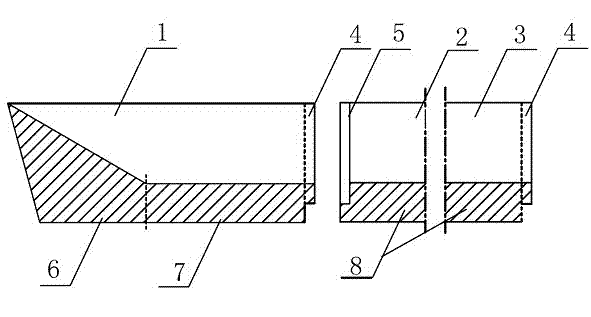

[0015] see figure 1 , the metallurgical batching turning steel weighing device of the present invention will be further described in detail through specific examples below. This embodiment includes a straight punching groove 1 and multiple groups of diversion grooves, and the diversion grooves include a first diversion groove 2 and a second diversion groove 3 . The straight-flush tank 1 includes a receiving part 6 and a return part 7 built in the bottom of its tank body. The return part 7 is a cube with an upper plane parallel to the bottom plane of its tank body. The receiving part 6 is a The bottom plane has a cube with an inclined surface, the straight line passing through the highest point of the inclined surface is connected to the top of the tank body of the straight flushing tank 1, and the straight line passing through the lowest point of the inclined surface is connected to the upper plane of the return section 7, and the diversion groove The bottom of the tank body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com