Surface protection film

A technology of surface protection film and back layer, applied in the direction of film/sheet adhesive, adhesive type, coating, etc., which can solve problems such as difficulty in peeling off, complicated coating process, and lack of effect , to achieve excellent sliding properties and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

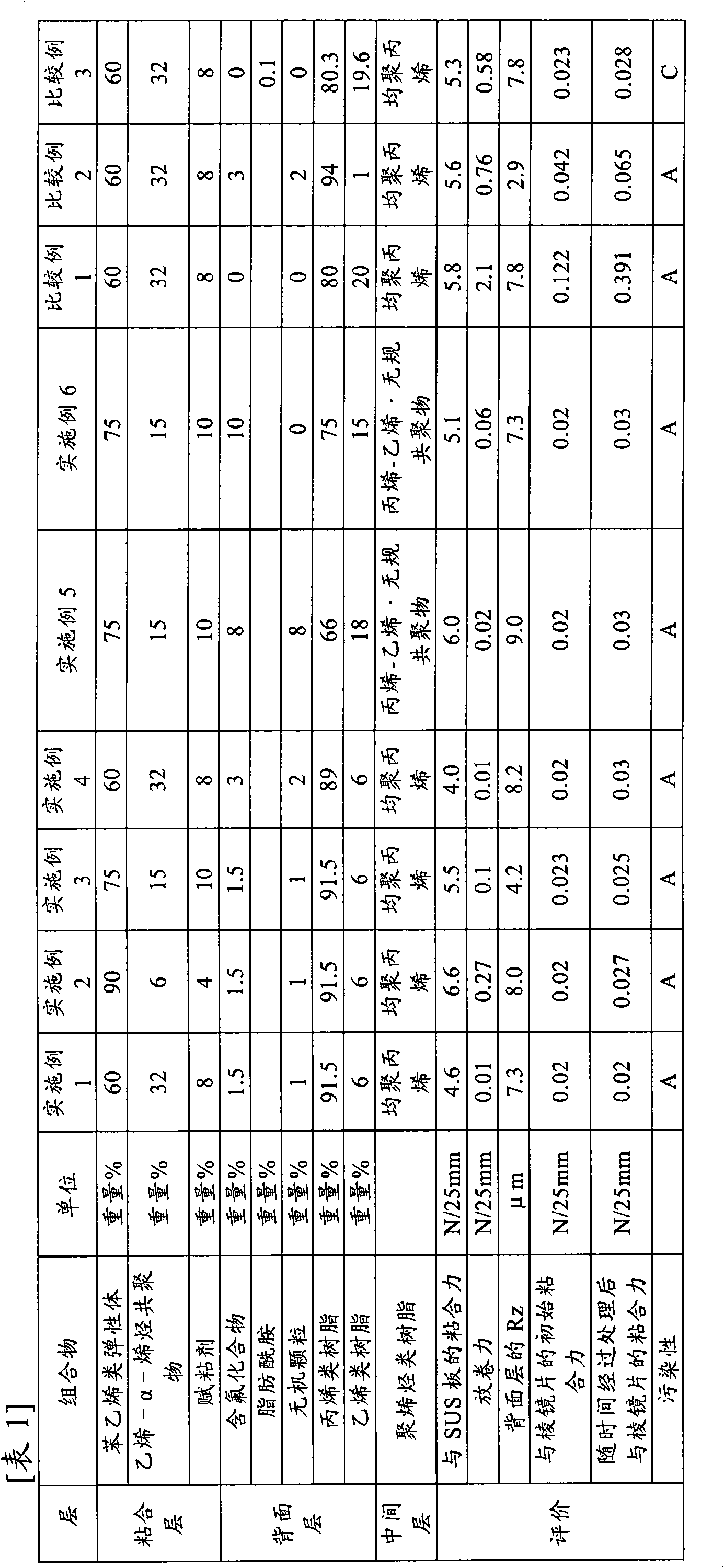

Embodiment 1

[0095] Adhesive layer resin: A resin composition consisting of a styrene-based elastomer containing 10% by weight of styrene and having an MFR of 10 g / 10 minutes at 230° C. was uniformly mixed with a Henschel mixer. · Butadiene · random copolymer 60% by weight; as an ethylene-α-olefin copolymer, the density is 0.921kg / m 3 And 20% by weight of hexene copolymerized polyethylene (linear low-density polyethylene) with MFR of 5g / 10 minutes at 190°C; and 20% by weight of masterbatch with 40% by weight of hydrogenated terpene phenol as a tackifier .

[0096] Here, as the masterbatch containing 40% by weight of the hydrogenated terpene phenol, a masterbatch of 40% by weight of the hydrogenated terpene phenol and 60% by weight of the above-mentioned hexene-copolymerized polyethylene was used in advance with a twin-screw extruder.

[0097] Back layer resin: 45% by weight of homopolypropylene with an MFR of 5 g / 10 min at 230°C and 24% by weight of propylene-ethylene random copolymer wit...

Embodiment 2、3

[0112] In addition, as the adhesive layer resin of Example 3, a material obtained by uniformly mixing a resin composition composed of a resin composition containing 10% by weight of a styrene component and having an MFR of 10 g / 10 at 230° C. with a Henschel mixer was used. Min styrene·butadiene·random copolymer was 75% by weight, and the tackifier used in Example 2 was 40% by weight and masterbatch 25% by weight. Except for this, the films of Examples 2 and 3 were produced as the same resin configuration as in Example 1.

[0113] In both Examples 2 and 3, in order to cut to a predetermined width, the film was placed on a cutter and rolled into a product roll, and a sample film was obtained smoothly in both cases. Table 1 shows properties of the obtained film.

[0114] (Example 4)

Embodiment 4

[0116] (Example 5)

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com