Mono-crystalline silicon piece texturing alcohol-free additives and using method thereof

A single crystal silicon wafer and additive technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of unsatisfactory texturing effect, poor texturing stability, and large pyramid size, etc. The effect of reducing consumption costs, reducing waste liquid treatment costs, and inexpensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

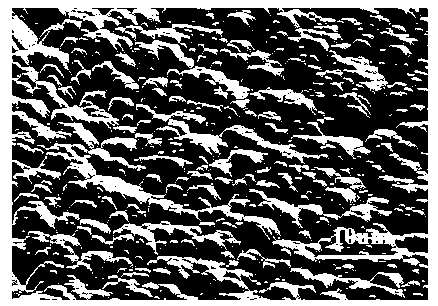

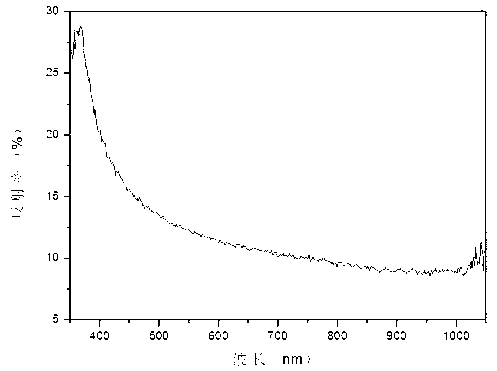

Image

Examples

Embodiment Construction

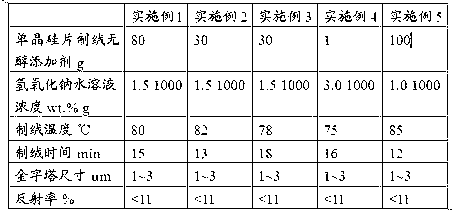

[0019] The following examples illustrate the non-alcoholic additive for texturing monocrystalline silicon wafers and its application method in the present invention with detailed specific implementation methods, but the present invention is not limited to the following examples. Table 1 shows the composition and dosage of the non-alcoholic additive for texturing monocrystalline silicon wafers, and Table 2 shows the conditions and effects of using the non-alcoholic additive for texturing monocrystalline silicon wafers.

[0020] Table 1 Composition and dosage of alcohol-free additives for monocrystalline silicon wafer texturing

[0021] Example 1 Example 2 Example 3 Example 4 Example 5 Diisopropanolamine / g —— —— 10 20 25 Triisopropanolamine / g 20 30 —— 20 —— Sodium Benzoate / g 8 10 5 8 6 water / g 100 100 100 100 100

[0022] Table 2 The use conditions and effects of alcohol-free additives for monocrystalline silicon w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com