Polylactic acid nucleating agent, preparation method and application thereof

A technology of nucleating agent and polylactic acid, which is applied in the field of new polylactic acid nucleating agent, can solve the problems of affecting product performance, reducing molecular weight, severe thermal degradation, etc., and achieves avoiding thermal degradation, good transparency, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Add 150Kg L-lactic acid into the reaction kettle, first vacuumize under mechanical stirring, dehydrate at 80°C for 2 hours, then raise the temperature to 150°C, control the vacuum at 5000Pa, and react for 10 hours to obtain poly-L - Lactic acid; repeat the above reaction process, change L-lactic acid to D-lactic acid, and finally obtain poly D-lactic acid. The terminal carboxyl group contents of poly-L-lactic acid and poly-D-lactic acid were 20.3 mgKOH / g and 19.5 mgKOH / g, respectively, and the molecular weight distributions were 1.23 and 1.19, respectively.

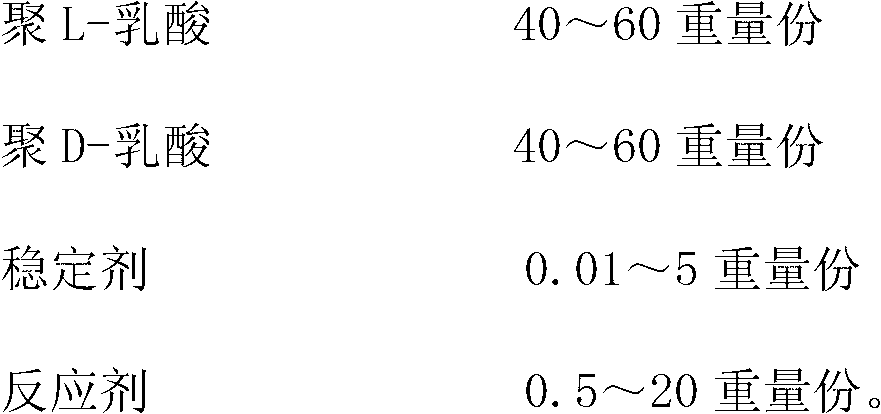

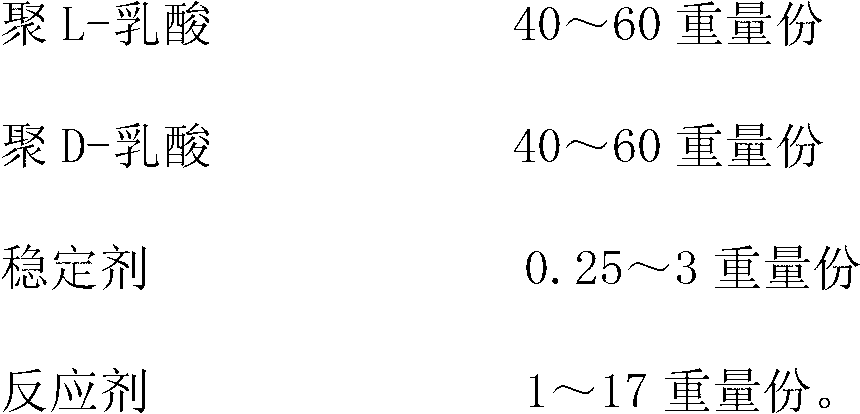

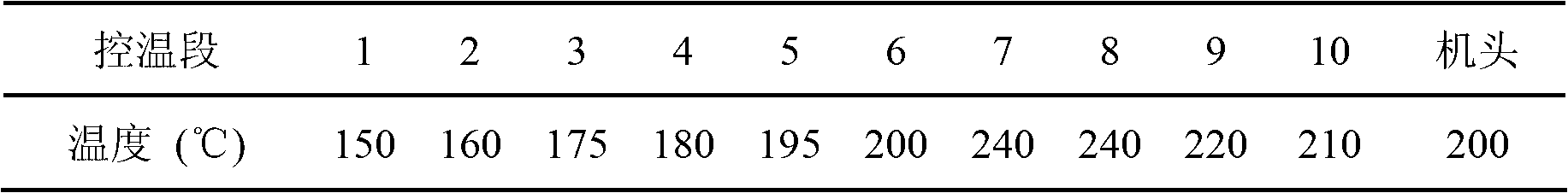

[0044] (2) Weigh 50 parts by weight of each of the poly-L-lactic acid and poly-D-lactic acid obtained in the previous step, mix them, and extrude them with a twin-screw extruder at a speed of 100 rpm. The temperature settings of the extruder are shown in Table 1. Add 6 parts by weight of dicyclohexylcarbodiimide (purchased from Bailingwei Technology Co., Ltd.) and 0.5 parts by weight of triphenyl phosphite from...

Embodiment 2

[0049] (1) Add 150Kg L-lactic acid into the reaction kettle, first vacuumize under mechanical stirring, dehydrate at 80°C for 2 hours, then raise the temperature to 170°C, control the vacuum at 2000Pa, and react for 8 hours to obtain poly-L - Lactic acid; repeat the above reaction process, change L-lactic acid to D-lactic acid, and finally obtain poly D-lactic acid. The terminal carboxyl group contents of poly-L-lactic acid and poly-D-lactic acid are 10.5 mgKOH / g and 10.8 mgKOH / g, respectively, and the molecular weight distributions are 1.55 and 1.58, respectively.

[0050] (2) Mix the poly-L-lactic acid and poly-D-lactic acid obtained in the previous step with 45 parts by weight of poly-L-lactic acid and 55 parts by weight of poly-D-lactic acid, and extrude them with a twin-screw extruder at a speed of 120 rpm. The outlet temperature settings are shown in Table 2. Add 1 part by weight of glycidyl methacrylate and 1 part by weight of tris(2,4-di-tert-butylphenyl) phosphite fr...

Embodiment 3

[0055] (1) Add 150Kg L-lactic acid into the reaction kettle, first vacuumize under mechanical stirring, dehydrate at 90°C for 1 hour, then raise the temperature to 140°C, control the vacuum at 500Pa, and react for 4 hours to obtain poly-L - Lactic acid; repeat the above reaction process, change L-lactic acid to D-lactic acid, and finally obtain poly D-lactic acid. The terminal carboxyl group contents of poly-L-lactic acid and poly-D-lactic acid were 46.5 mgKOH / g and 48.6 mgKOH / g, respectively, and the molecular weight distributions were 1.17 and 1.15, respectively.

[0056] (2) Mix the poly-L-lactic acid and poly-D-lactic acid obtained in the previous step with 55 parts by weight of poly-L-lactic acid and 45 parts by weight of poly-D-lactic acid, and extrude them with a twin-screw extruder at a speed of 200 rpm. The outlet temperature settings are shown in Table 3. 10 parts by weight of 2,2′-bis(2-oxazoline) (purchased from Bailingwei Technology Co., Ltd.), 0.05 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com