Solid lubricating high-temperature anti-wearing powder composition and preparation method of compound coating of composition

A high-temperature wear-resistant and solid-lubricating technology, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., to achieve the effects of fine grain size, increased compatibility and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Tungsten disulfide (WS 2 ) powder surface treatment such as pickling, alkali washing and activation, and then nickel sulfate (Ni 2 SO 4 ·6H 2 O) as the main salt, sodium hypophosphite (NaH 2 PO 2 ·H 2 O) is the reducing agent, including complexing agent, catalyst, buffering agent, etc., and the plating solution is prepared, and tungsten disulfide (WS 2 ) powder in the plating solution, using the electroless plating process, the plating temperature is 88 ℃, the plating time is 3 hours, and the plating solution is fully stirred during plating to ensure that the particles are dispersed, and the surface-coated Ni-P alloy disulfide is obtained. Tungsten, counted as WS 2 (Ni-P).

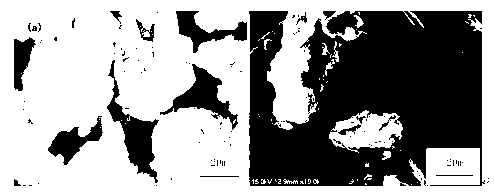

[0021] See attached figure 1 , the tungsten disulfide (WS) coated with Ni-P alloy provided by this embodiment 2 (Ni-P)) powder EDS energy spectrum; carry out energy spectrum analysis on the Ni-P cladding layer of the area taken, and measure the content of each element, by figure 1 It can b...

Embodiment 2

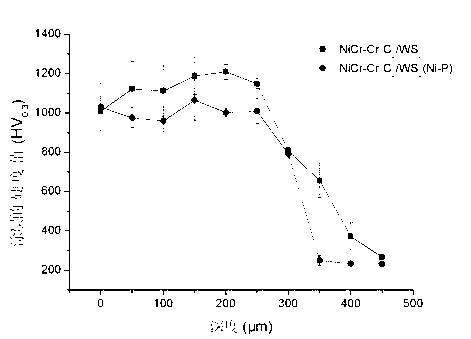

[0024] Adopt the chemical plating method of embodiment one to prepare WS 2 (Ni-P), according to table 1 weight percent proportioning each element, obtains NiCr-Cr with mechanical ball mill mixing method 3 C 2 / WS 2 (Comparative example, WS 2 30wt.%) and NiCr-Cr 3 C 2 / WS 2 (Ni-P) (WS 2 (Ni-P) is 30wt.%) alloy powder mixture, the powder particle size reaches 200-300 mesh.

[0025] Table 1

[0026]

[0027] (3) Use methyl cellulose as a binder, mix it with the above two powder mixtures respectively to form a paste, spread a pre-coated layer on the surface of austenitic stainless steel (0Cr18Ni9), and dry it.

[0028] (4) Irradiate the pre-coated coating with a laser with a power of 1.5 kW, and blow inert gas to the molten pool at the same time to avoid oxidation of the molten pool surface; the laser uses CO 2 Laser, the rectangular spot size is 6 mm × 3 mm, and the laser scanning speed is 4 mm / s.

[0029] (5) According to the size of the austenitic stainless steel ...

Embodiment 3

[0044] The alloy powder mixture was obtained by the method in Example 2.

[0045] The 2123 phenolic resin material is dissolved in ethanol as an adhesive, and the 2123 phenolic resin is a solid phenolic resin formed by polycondensation of phenol and formaldehyde under the action of an acidic catalyst. The binder is blended with the powder mixture, pre-coated on the surface of austenitic stainless steel (0Cr18Ni9), and dried.

[0046] The pre-laying coating was irradiated with a laser with a power of 1.5 kW, and an inert gas was blown to the molten pool to avoid oxidation of the surface of the molten pool; the laser used CO 2 Laser, the rectangular spot size is 6 mm × 3 mm, and the laser scanning speed is 4 mm / s.

[0047] According to the size of the austenitic stainless steel (0Cr18Ni9) substrate, a continuous coating can be obtained by single-pass laser scanning or multi-pass laser scanning. The lapping rate of multiple laps is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

| Average microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com