surface protection film

A surface protection film and back layer technology, applied in flexible coverings, electronic equipment, applications, etc., can solve problems such as difficulty in peeling off, reduced adhesion, easy peeling, etc., and achieve good reproducibility and excellent sliding properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

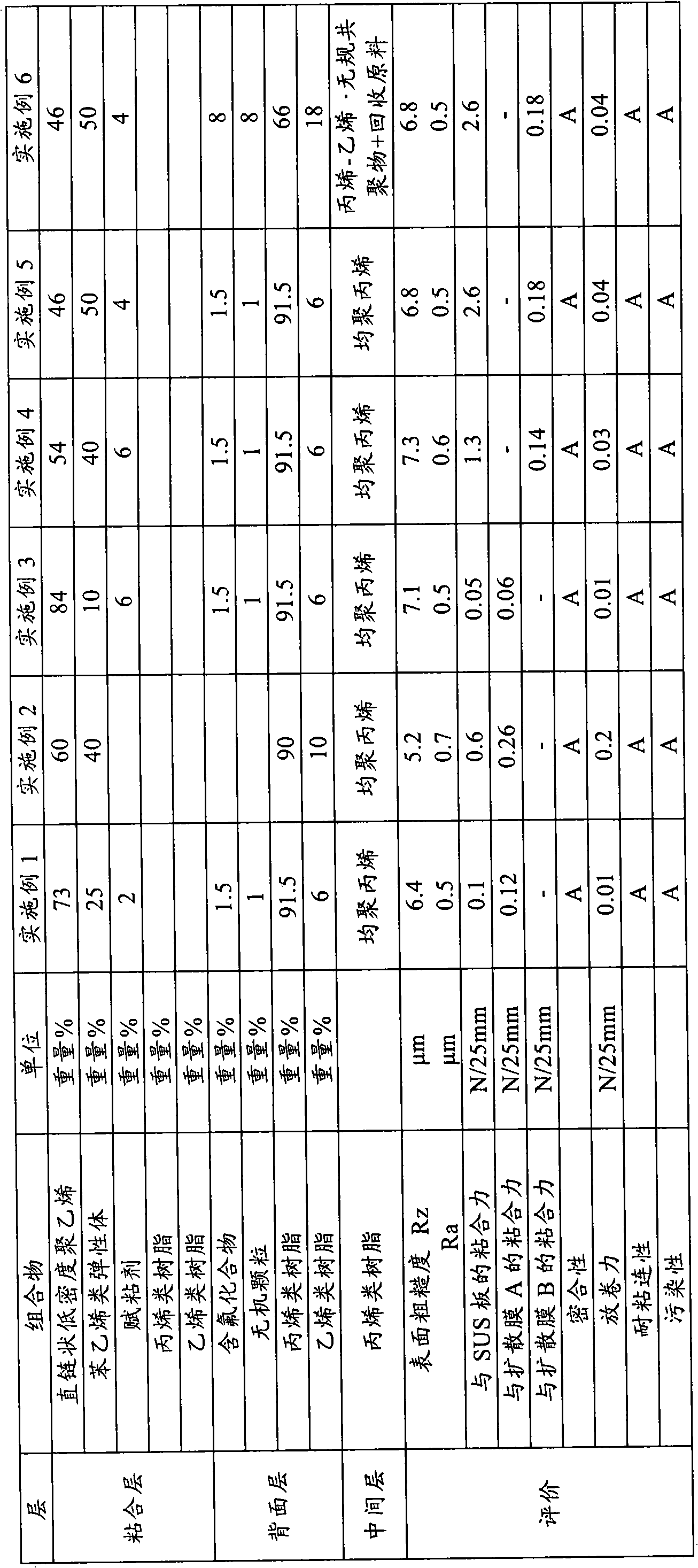

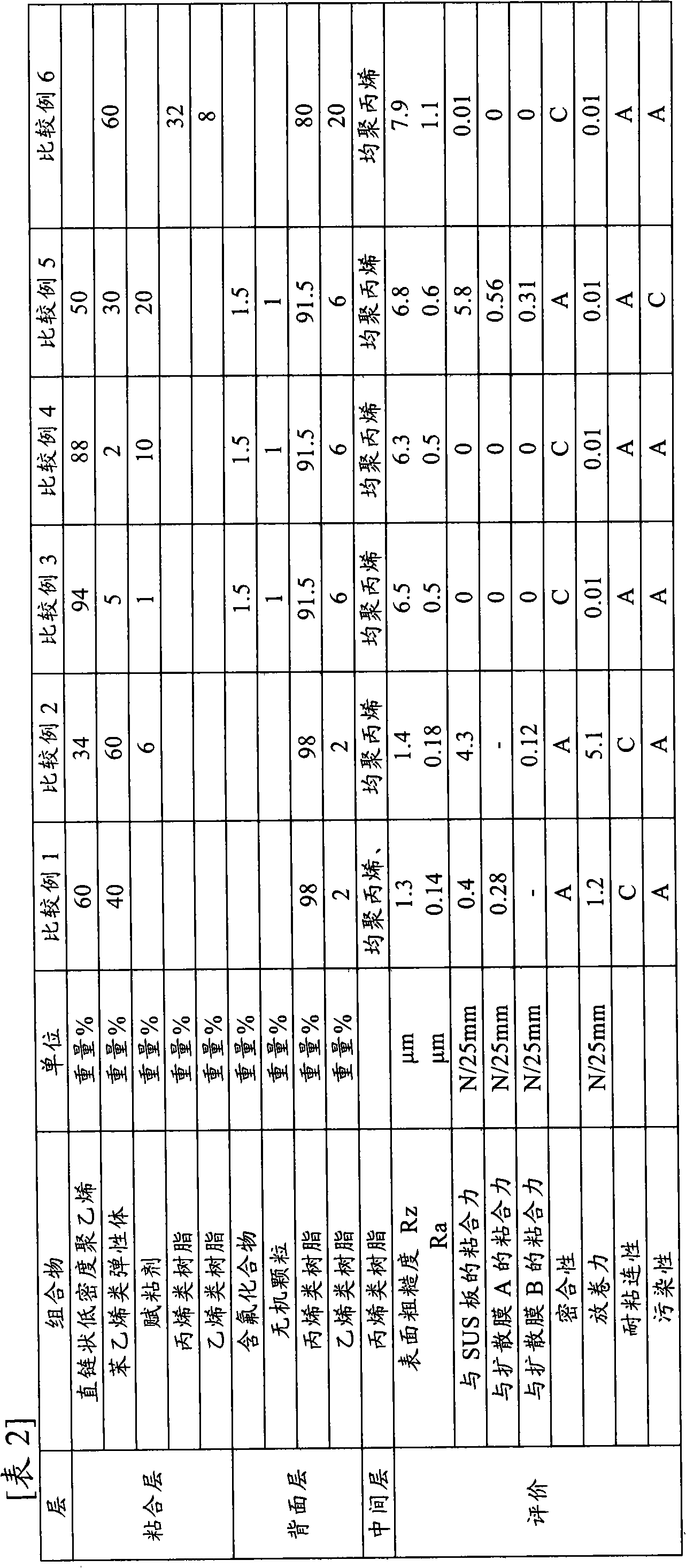

Embodiment 1

[0095] The constituent resins of the respective layers were prepared as follows.

[0096] Adhesive layer resin: uniformly mix a resin composition consisting of the following materials with a Henschel mixer: density 0.91kg / m 3 70% by weight of linear low-density polyethylene (hexene copolymerized polyethylene) having an MFR of 15 g / 10 minutes at 190°C; styrene containing 10% by weight of styrene and having an MFR of 10 g / 10 minutes at 230°C - butadiene·random copolymer 25% by weight; and 5% by weight of master pellet (masterpellet) 40% by weight of hydrogenated terpene phenol as tackifier.

[0097] Here, as the masterbatch containing 40% by weight of the hydrogenated terpene phenol, a masterbatch of 40% by weight of the above-mentioned terpene phenol and 60% by weight of the above-mentioned linear low-density polyethylene was used in advance with a twin-screw extruder.

[0098] Resin for the back layer: 45% by weight of homopolypropylene with an MFR of 5 g / 10 minutes at 230°C ...

Embodiment 2

[0109] As the adhesive layer resin, a resin composition consisting of the following materials was uniformly mixed with a Henschel mixer: Density 0.91kg / m 3 60% by weight of linear low-density polyethylene (hexene copolymerized polyethylene) having an MFR of 15 g / 10 minutes at 190°C; 40% by weight of ethylene-butadiene random copolymer.

[0110] In addition, as the back layer resin, the composition is: 50% by weight of homopolypropylene with an MFR of 5 g / 10 minutes at 230°C; 40% by weight of a propylene-ethylene random copolymer with an MFR of 35 g / 10 minutes at 230°C (ethylene content 5% by weight); and a density of 0.92 g / cm at an MFR of 2 g / 10 min at 190°C 3 10% by weight of low-density polyethylene. The intermediate layer was carried out in the same manner as in Example 1, and a 40 μm laminated film was produced by co-extrusion, and rolled into a roll.

[0111] Furthermore, in order to cut into a predetermined width, it puts it on the cutter and rolls it into a product ...

Embodiment 3

[0116] As the adhesive layer resin of Example 3, the compounding ratio was changed to 75% by weight of the same linear low-density polyethylene (hexene copolymerized polyethylene) as that used in Example 1, and the same (as in Example 1) 10% by weight of styrene-butadiene random copolymer, and 15% by weight of the masterbatch of 40% by weight of the same hydrogenated terpene phenol, in the same way as in Example 1 The method was to manufacture 40 μm laminated films by co-extrusion, respectively, and wound them into rolls.

[0117] Then, in order to cut into a predetermined width, it was placed on a cutter and wound up as a product roll, and a sample film could be obtained smoothly. Table 1 shows properties of the obtained film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com