Digitalized-control low-voltage direct-current power source energy feedback type electronic loading boosting system

A low-voltage direct current, energy feedback technology, applied in the direction of control/regulation system, adjustment of electrical variables, conversion of DC power input to DC power output, etc., can solve problems such as not suitable for low-voltage and high-current DC power supply aging tests, and achieve aging test problems, increased device efficiency, and the effects of easy programming control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

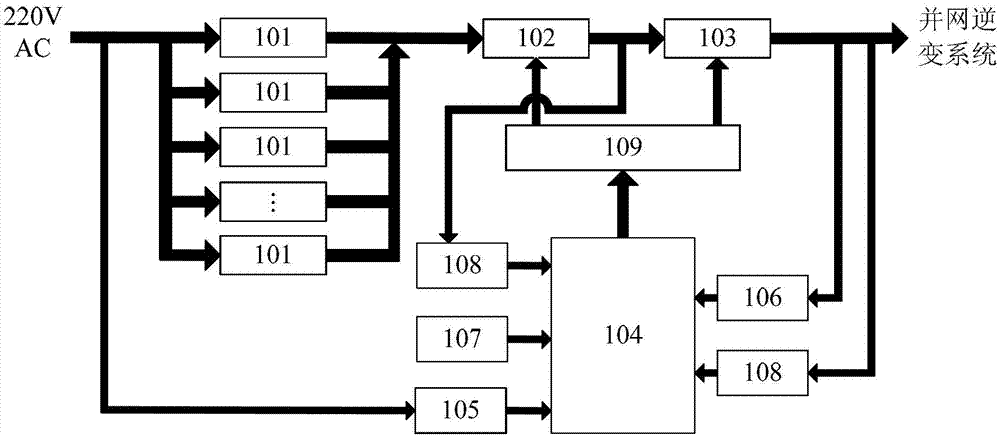

[0036] Such as figure 1 As shown, a digitally controlled low-voltage DC power supply energy feedback electronic load boosting system according to the present invention, the system includes a main circuit and a control circuit. The main circuit is composed of a Boost step-up module 102 and a DC-DC step-up conversion module 103 connected in sequence, the Boost step-up module 102 is connected with a parallel low-voltage DC power supply 101, and the DC-DC step-up conversion module 103 is connected with The energy feedback type electronic load is connected to the grid-connected inverter system; the control circuit includes a fault protection circuit module, a current and voltage sampling and signal processing module 108, a DSP embedded system module 104 and a high-frequency drive module 109 connected to each other.

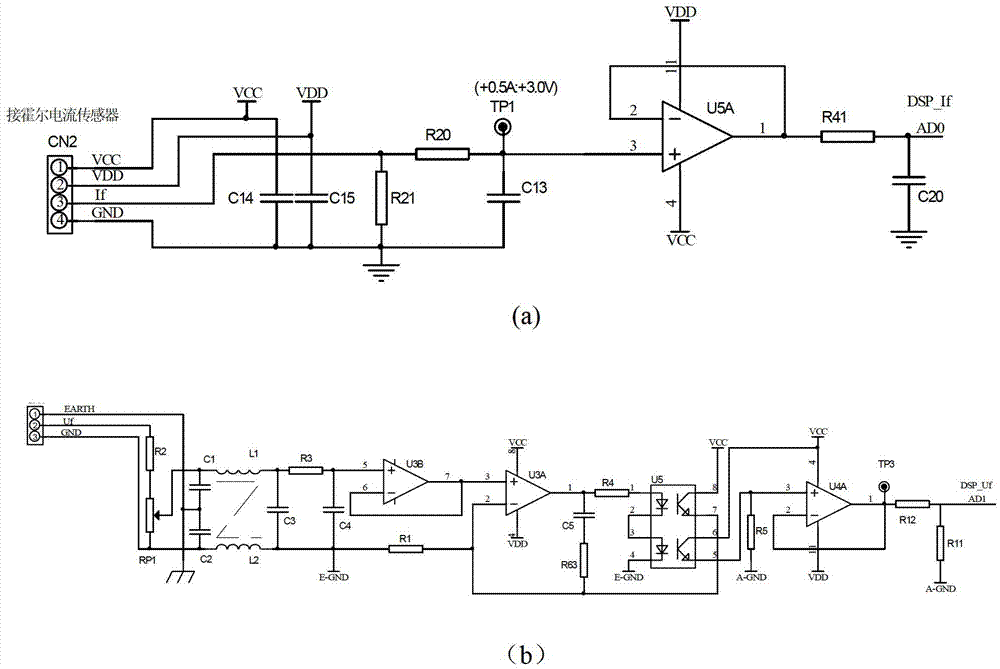

[0037] The fault protection circuit module includes an overvoltage and undervoltage fault protection circuit 105, an overcurrent fault protection circuit 106, and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com