Method for preparing monocrystalline silicon carbide nano-wires on flexible carbon fiber substrate

A technology for silicon carbide nanowires and single crystal silicon carbide, applied in the field of preparing single crystal silicon carbide nanowires, can solve the problems of complex preparation method, low yield, poor orientation of silicon carbide nanowires, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

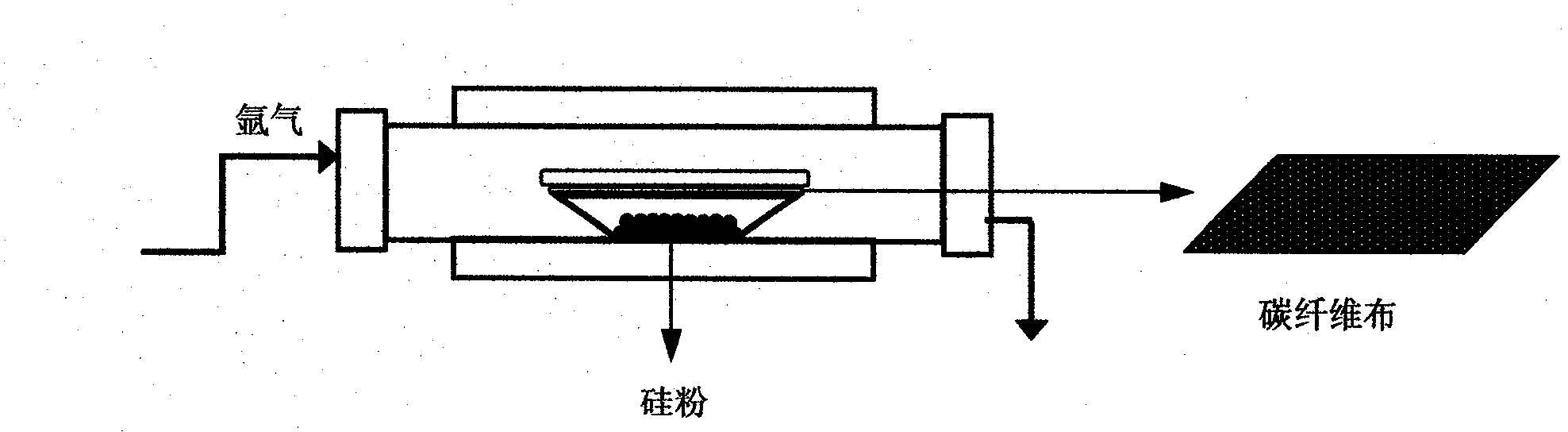

[0020] The whole silicon carbide nanowire growth process includes the following steps:

[0021] Step 1: Soak a commercially available carbon fiber cloth in 0.3 mol / l ferric nitrate solution for 1 hour, then take it out, and dry it in a drying box.

[0022] Step 2: Put 14 grams of silicon powder into the alumina crucible, then cover the weighed 6 grams of carbon fiber cloth, and press the top of the carbon fiber cloth with a cover;

[0023] Step 3: Put the whole reaction device into the tube furnace, evacuate to 0.1Pa, and then pass in argon protection;

[0024] Step 4: Heat to 1500°C, keep warm for 6 hours, and then cool naturally.

[0025] Step 5: Take out the reacted carbon fiber cloth directly. At this time, a large number of silicon carbide nanowire arrays are lined with the carbon fiber cloth.

[0026] see figure 1 : Schematic diagram of the device for growing silicon carbide nanowire arrays and reacting in a horizontal tube furnace

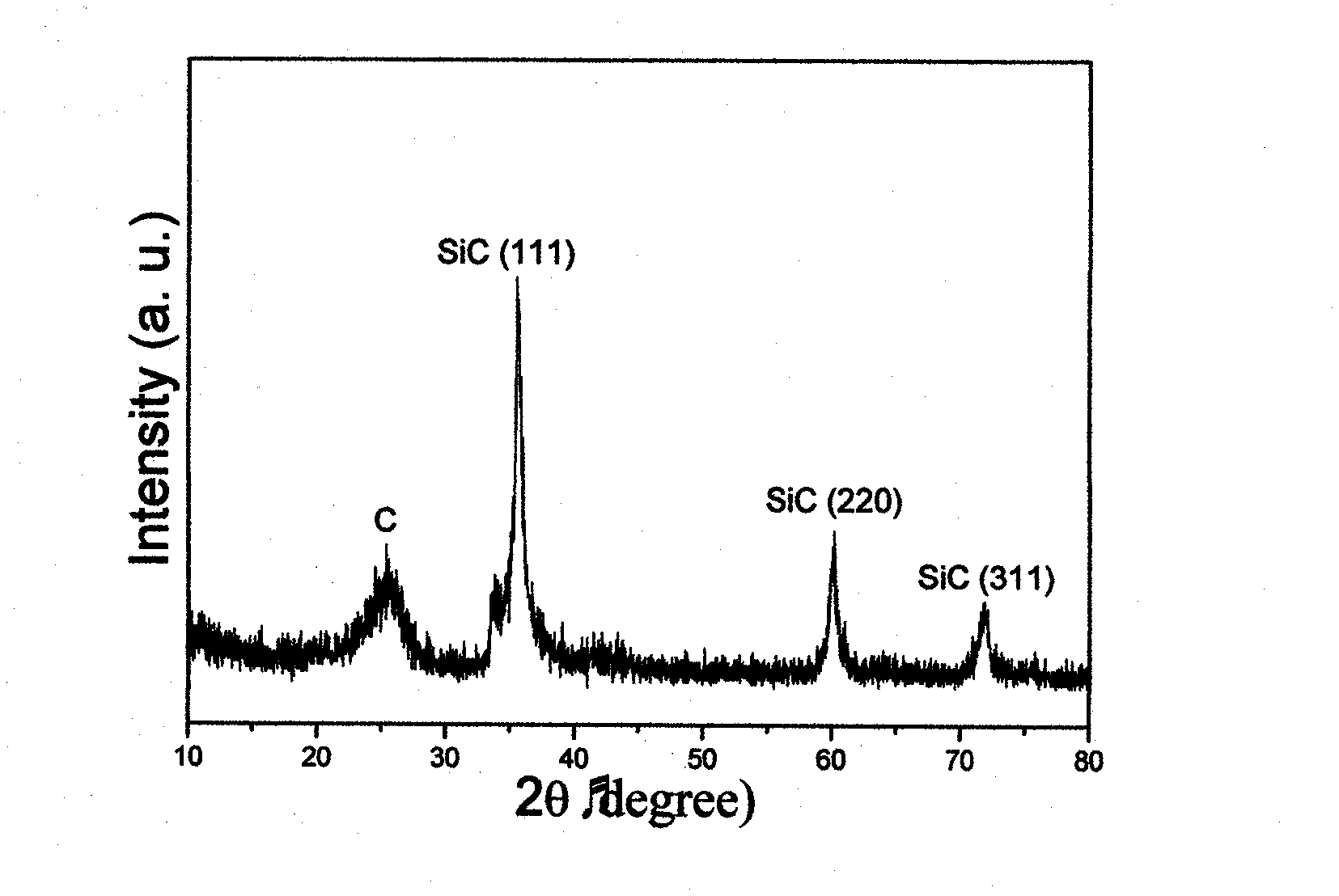

[0027] see figure 2 : The XRD p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com