Method for sealing holes of micro arc oxidation film at room temperature

A technology of micro-arc oxidation and normal temperature, which is applied in the direction of anodic oxidation, etc., can solve the problems of high cost, more sealing agents for anodized film, and difficulty in achieving effective sealing of micro-arc oxidation film, so as to improve corrosion resistance and seal holes. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

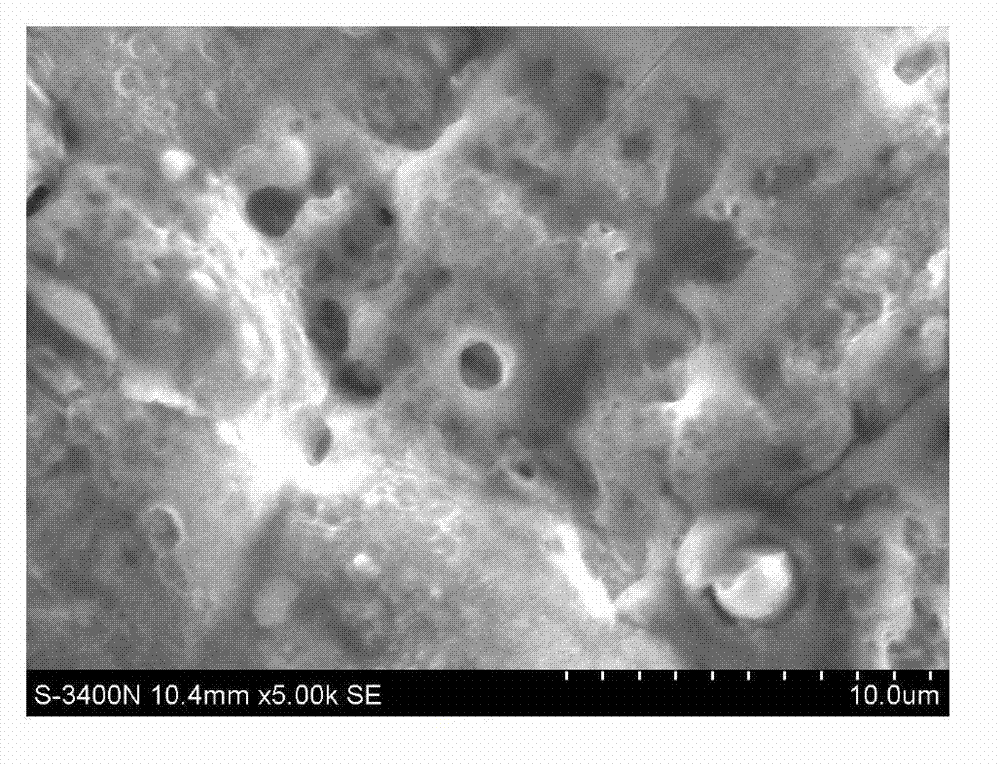

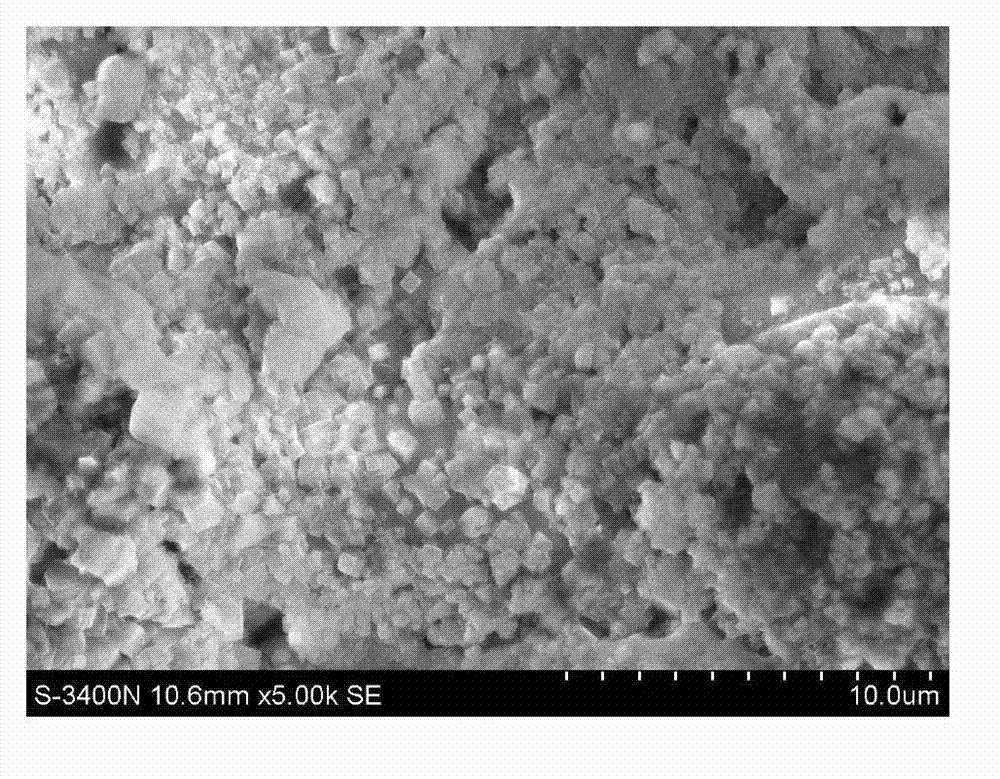

[0021] Select an aluminum alloy micro-arc oxidation film, use 20L of deionized water, add 100g of sodium silicate pentahydrate, 160g of nickel fluoride, 2g of boric acid, and 2g of potassium fluorozirconate to prepare a sealing agent. After the sealing agent is prepared, let it stand for 2 hours, then soak the micro-arc oxidation film in the sealing agent solution at room temperature for 30 minutes, then take it out and dry it naturally.

Embodiment 2

[0023] Select a magnesium alloy micro-arc oxidation film, use 20L of deionized water, add 300g of sodium silicate pentahydrate, 80g of nickel acetate, 10g of boric acid, 2g of potassium fluozirconate, and 10g of thiourea to prepare a sealing agent. After the sealing agent is prepared, let it stand for 2 hours, soak the micro-arc oxidation film in the sealing agent solution at room temperature for 30 minutes, then take it out and dry it naturally.

Embodiment 3

[0025] Select a titanium alloy micro-arc oxidation film, use 20L of deionized water, add 200g of sodium silicate nonahydrate, 40g of nickel fluoride, 40g of nickel acetate, 20g of boric acid, and 20g of thiourea to prepare a sealing agent. After the sealing agent is prepared, let it stand for 2 hours, soak the micro-arc oxidation film in the sealing agent solution at room temperature for 30 minutes, then take it out and dry it naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com