Precision anti-blocking liquid fertilizing gun

A fertilizing gun and anti-blocking technology, applied in the field of precise anti-blocking liquid fertilizing guns, can solve the problems of complex structure, easy blockage of the gun head, inability to effectively control the amount of fertilizer liquid, etc., and achieve the effect of simple operation and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

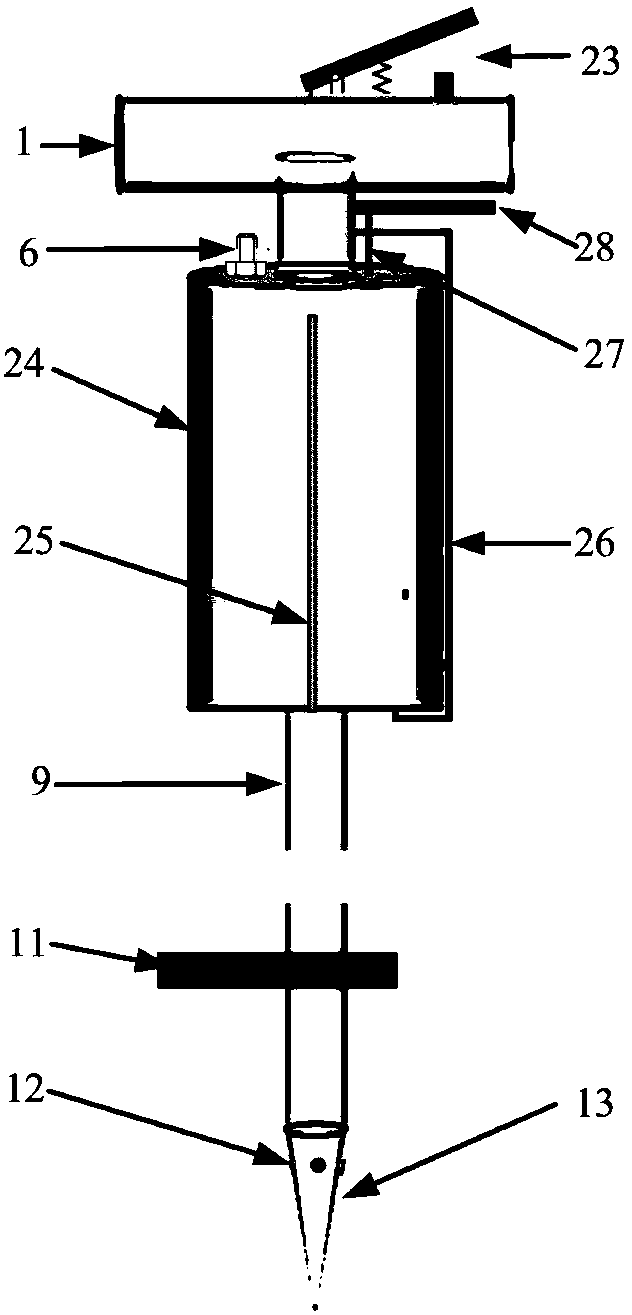

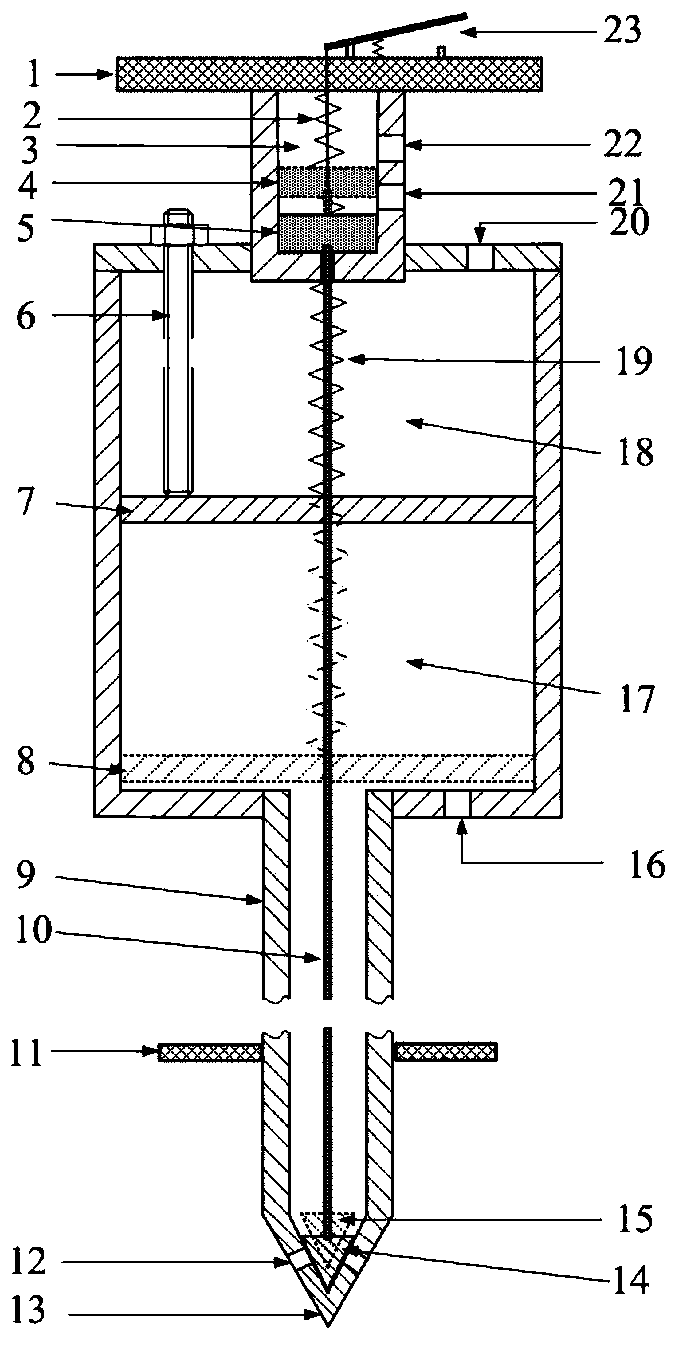

[0026] see figure 1 and figure 2 , the present invention precision anti-clogging liquid fertilization gun, including a switch combination 23, and sequentially communicated liquid measuring barrel 24, gun shaft 9 and an inverted tapered gun head 13.

[0027] Wherein, the liquid measuring barrel 24 is a circular barrel or a square barrel, and a dispensing chamber 3 is arranged above it, and its inside is divided into an upper chamber 18 and a lower chamber 17 which are mutually isolated by a drain plunger capable of moving up and down. 18 is provided with a fertilization rate regulating device that limits the position of the highest point of the drainage plunger, such as figure 2 The position of the drain plunger in a 7; preferred, such as figure 2 As shown, the fertilization amount adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com