Experimental device and method for measuring solubility of overflowed gas

An experimental device and solubility technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of inability to reflect wellbore flow conditions, solubility data errors, and inaccurate drilling fluid volume measurement, etc., achieve high accuracy, good sealing effect, and improve experimental results. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

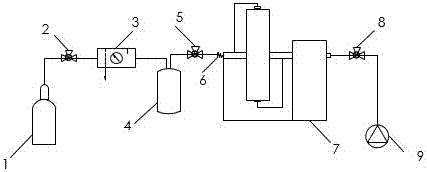

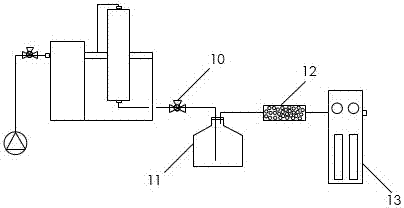

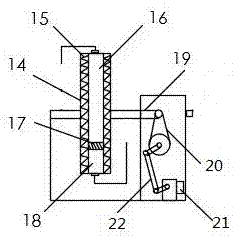

[0040] Adopt the measurement method of described a kind of experimental device of measuring overflow gas solubility, comprise the following steps:

[0041] ① Preparation: Use petroleum ether to clean the pipeline and container, estimate the drilling fluid and gas volume required for a single sample transfer, adjust the position of the piston 17 in the high temperature and high pressure sample preparation device 7, and reserve 200ml of the volume of the reaction chamber 16;

[0042] ② Sample transfer: put 200ml of unweighted oil-based drilling fluid into the reaction chamber 16 of the high-temperature and high-pressure sampler, and measure the drilling fluid density ρ l ;Inject the gas in the gas cylinder 1 into the intermediate container 4 at 10MPa through the booster 3; open the hydraulic oil end valve 8 of the high-temperature and high-pressure sampler, and release 400ml of hydraulic oil; open the valve 5, and inject the gas in the intermediate container 4 The high temperatu...

Embodiment 2

[0051] Adopt the measurement method of described a kind of experimental device of measuring overflow gas solubility, comprise the following steps:

[0052] ① Preparation: Use petroleum ether to clean the pipeline and container, estimate the volume of drilling fluid and gas required for a single sample transfer, adjust the position of the piston 17 in the high-temperature and high-pressure sampler 7, and reserve a reaction chamber volume of 200ml;

[0053] ② Sample transfer: put 200ml of unweighted synthetic base drilling fluid into the reaction chamber 16 of the high temperature and high pressure sampler, and measure the drilling fluid density ρ l ;Inject the gas in the gas cylinder 1 into the intermediate container 4 at 20MPa through the booster 3; open the hydraulic oil end valve 8 of the high-temperature and high-pressure sampler, and release 200ml of hydraulic oil; open the valve 5, and inject the gas in the intermediate container 4 The high temperature and high pressure s...

Embodiment 3

[0062] Adopt the measurement method of described a kind of experimental device of measuring overflow gas solubility, comprise the following steps:

[0063] ① Preparation: Use petroleum ether to clean the pipeline and container, estimate the volume of drilling fluid and gas required for a single sample transfer, adjust the position of the piston 17 in the high-temperature and high-pressure sampler 7, and reserve a reaction chamber volume of 700ml;

[0064] ② Sample transfer: put 700ml of unweighted water-based drilling fluid into the reaction chamber 16 of the high temperature and high pressure sampler, and measure the drilling fluid density ρ l ;Inject the gas in the gas cylinder 1 into the intermediate container 4 at 10MPa through the booster 3; open the hydraulic oil end valve 8 of the high-temperature and high-pressure sampler, and release 210ml of hydraulic oil; open the valve 5, and inject the gas in the intermediate container 4 The high temperature and high pressure samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com