Synthesis method of high-base-number basic zinc carbonate lubricant additive

A technology of lubricating oil additives and synthesis methods, applied in the direction of additives, lubricating compositions, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

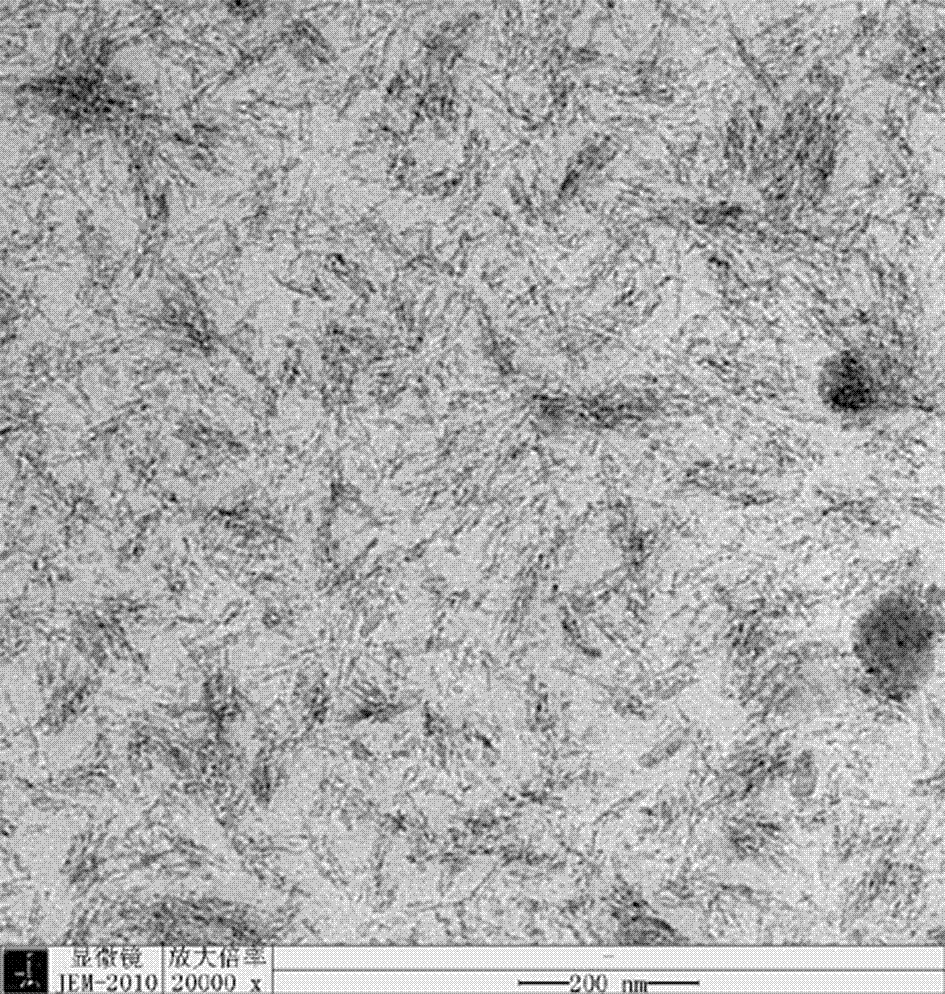

Image

Examples

Embodiment 1

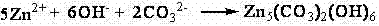

[0023] A kind of synthetic method of high alkali value basic zinc carbonate lubricating oil additive, it comprises the following steps:

[0024] 1) Install the three-neck flask with electric stirring, condenser, and dropping funnel, put in the prepared 30 mL 1.25mol / L zinc chloride aqueous solution, adjust the pH value to 8 with ammonia water, and then raise the temperature to 80°C, Start the stirrer, drop 60 mL of 1.5mol / L aqueous sodium bicarbonate solution under stirring conditions, and obtain a white basic zinc carbonate sol after reacting for 2 hours;

[0025] 2) Lower the basic zinc carbonate sol to 25°C, adjust the pH value to 7 with ammonia water, and then add 50 mL of dissolved 4.89 g of alkylbenzenesulfonic acid (molecular formula of alkylbenzenesulfonic acid: C 12 h 25 C 6 h 4 SO 3 H) Toluene solution, after reacting for 5 hours, a transparent oil-water two-phase system was obtained. The oil phase was separated and dried to obtain 9.02 g of oil-soluble basic zi...

Embodiment 2

[0027] A kind of synthetic method of high alkali value basic zinc carbonate lubricating oil additive, it comprises the following steps:

[0028] 1) Install the three-necked flask with electric stirring, condenser, and dropping funnel, put in the prepared 30 mL 1.25mol / L zinc nitrate aqueous solution, adjust the pH value to 7 with ammonia water, then raise the temperature to 50°C, and start Stirrer, drip 60 mL of 1.5mol / L sodium carbonate aqueous solution under stirring condition, obtain white basic zinc carbonate sol after reacting for 1h;

[0029] 2) Lower the basic zinc carbonate sol to room temperature, adjust the pH value to 7 with ammonia water, then add 14.27g stearic acid (C 17 h 35 COOH) in chloroform solution, after 8 hours of reaction, a transparent oil-water two-phase system was obtained. The oil phase was separated and dried to obtain 8.81 g of oil-soluble basic zinc carbonate nanoparticles.

Embodiment 3

[0031] A kind of synthetic method of high alkali value basic zinc carbonate lubricating oil additive, it comprises the following steps:

[0032] 1) Install the three-neck flask with electric stirring, condenser and dropping funnel, put in the prepared 30 mL 1.25mol / L zinc nitrate aqueous solution, adjust the pH value to 8 with ammonia water, then raise the temperature to 90°C, start Stirrer, drip 60 mL 3mol / L urea aqueous solution under stirring condition, obtain white basic zinc carbonate sol after reacting for 8 hours;

[0033] 2) Lower the basic zinc carbonate sol to 60 °C, adjust the pH value to 7 with ammonia water, and then add 80 mL of 7.1 g alkylthiophenol ((C 8 h 17 C 6 h 3 Oh) 2 S 2 ) in toluene, after 5 hours of reaction, a transparent oil-water two-phase system was obtained. The oil phase was separated and dried to obtain 11.2 g of oil-soluble basic zinc carbonate nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com