Semiaromatic moulding masses and their applications

一种半芳香族、模塑料的技术,应用在薄料处理、运输和包装等方向,能够解决未报道模塑料热稳定性的改善等问题,达到良好热老化稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

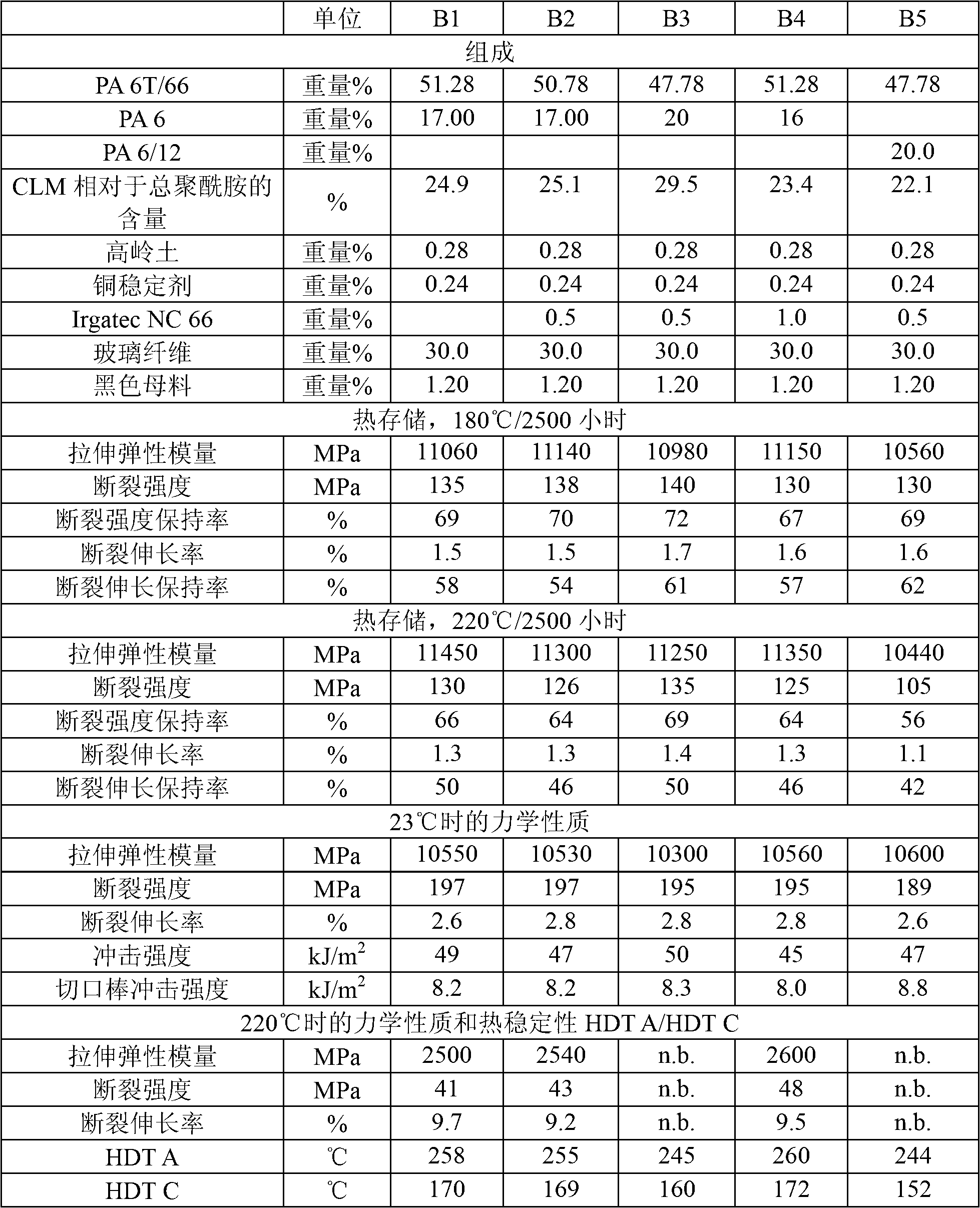

Embodiment B1~B5 and comparative example V1~V9

[0125] Molding compounds of the compositions given in Tables 1 and 2 were produced on a twin-screw extruder manufactured by Werner and Pfleiderer (type ZSK25). The polyamide pellets are distributed into the feed zone together with the additives, while the glass fibers are distributed into the polymer melt through the side feeder 3 of the housing unit before the nozzle. The housing temperature is set with a ramp up to 330°C. The production capacity of 10kg is realized at 150rpm~200rpm. The properties of the granules were measured after cooling and granulating the polymer strands in a water bath and drying at 120° C. for 24 hours.

[0126] The molding compound was then injection molded into ISO test bodies in an Arburg Allrounder 320-210-750 injection molding machine, provided that the barrel temperature in zones 1-4 was 325°C-340°C and the "cooling temperature" was 130°C .

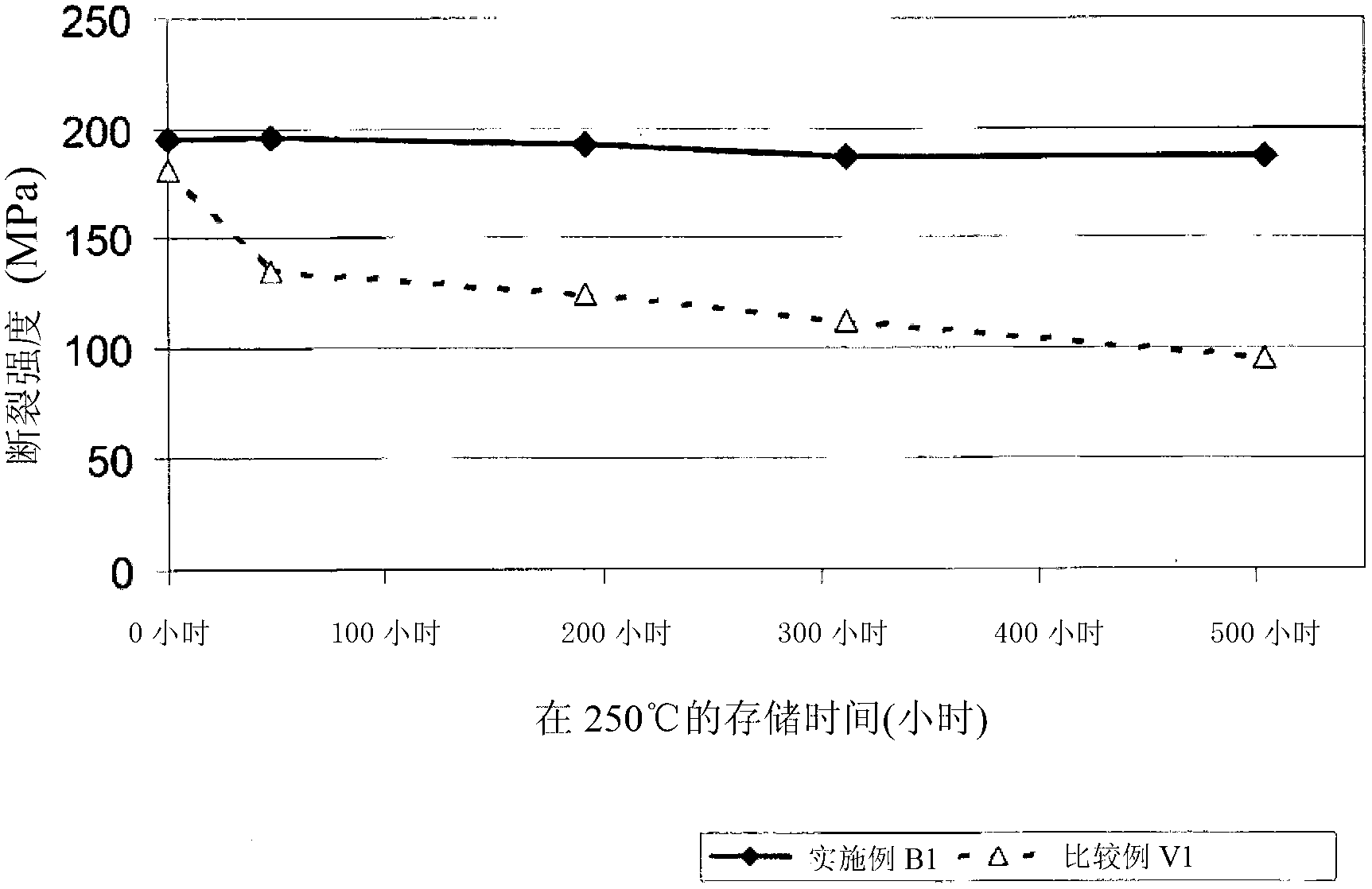

[0127] figure 1 The results of thermal storage at 250°C are shown. The breaking strength of the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com