Cycling treatment method for waste acid produced in production of hydroquinone

A hydroquinone and treatment method technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high equipment requirements, low yield, high cost of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

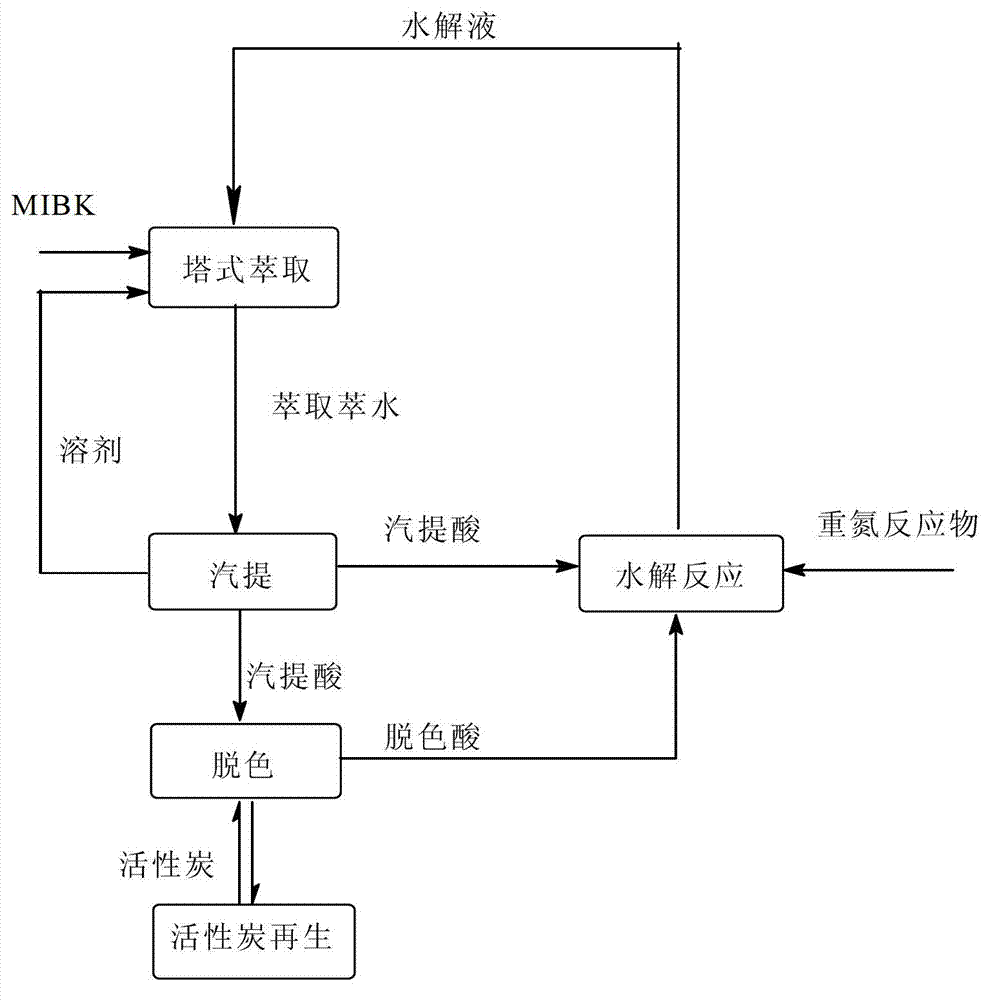

[0020] A waste acid recycling treatment method of hydroquinone, the concrete process steps of the method are described as follows:

[0021] (1) Extraction of hydrolyzate

[0022] After the hydrolysis reaction is completed, the temperature is lowered to 45~60°C, with methyl isobutyl ketone as the continuous phase and the hydrolyzate as the dispersed phase, the methyl isobutyl ketone and 840kg of hydrolyzate are respectively pumped into the high level tank through the metering pump for tower Extraction method, methyl isobutyl ketone is fed from the bottom of the tower, the flow rate is 8L / hr, the flow rate of the hydrolyzed liquid is 60L / hr from the top of the tower, the extraction temperature is controlled at 20~30°C, the extracted water layer is 789kg, and the oil layer is extracted 80kg.

[0023] During the tower extraction process, the feed ratio is adjusted according to the central control situation, and the hydroquinone content in the raffinate water layer is controlled t...

Embodiment 2~4

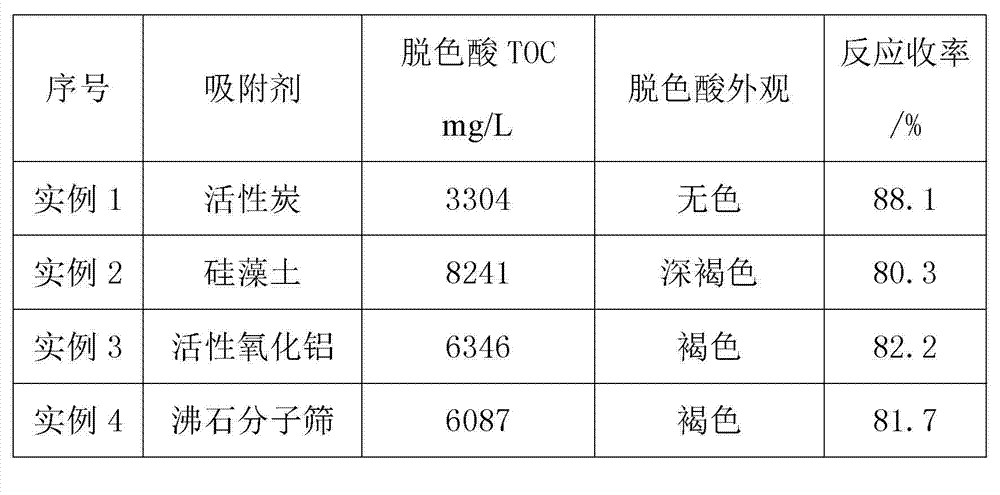

[0031] With the operation steps and reaction conditions of embodiment 1, just change the adsorbent used in the decolorization and decoking process, the experimental data are shown in Table 1:

[0032] Table 1 Comparison of Experimental Results of Embodiment 1 and 2~4

[0033]

[0034] From the above results, it can be seen that activated carbon as an adsorbent has a better effect on decoking and decolorizing waste acid.

Embodiment 5~11

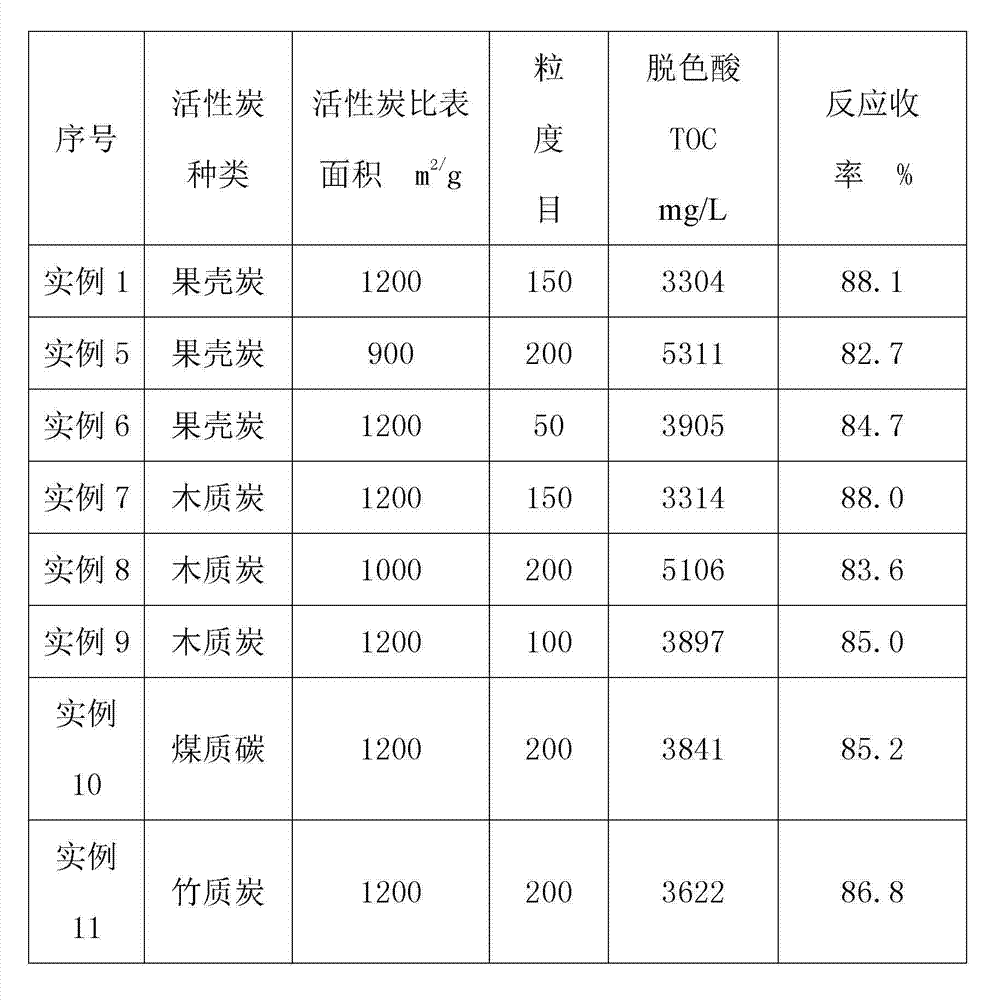

[0036] With the various operation steps and reaction conditions of embodiment 1, just change the specification of activated carbon used in the decoking and decolorization process, the experimental data are shown in Table 2:

[0037] Table 2 Comparison of Experimental Results of Embodiment 1 and 5-11

[0038]

[0039] When the specific surface area of activated carbon is greater than 1200 m 2 / g. When the particle size is greater than 150 mesh, the decoking and decolorization effects of shell charcoal and wood charcoal are better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com