Multiphase flow assembly type closed coagulation settling device

A coagulation-sedimentation and assembly-type technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, grease/oily substance/suspton removal device, liquid separation, etc., can solve the difficulty of increasing the operation and management of sewage stations, equipment separation Problems such as low efficiency of accumulating sewage and affecting sewage treatment efficiency can achieve the effect of improving comprehensive treatment capacity, facilitating oil collection and sludge discharge, and reducing operating workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

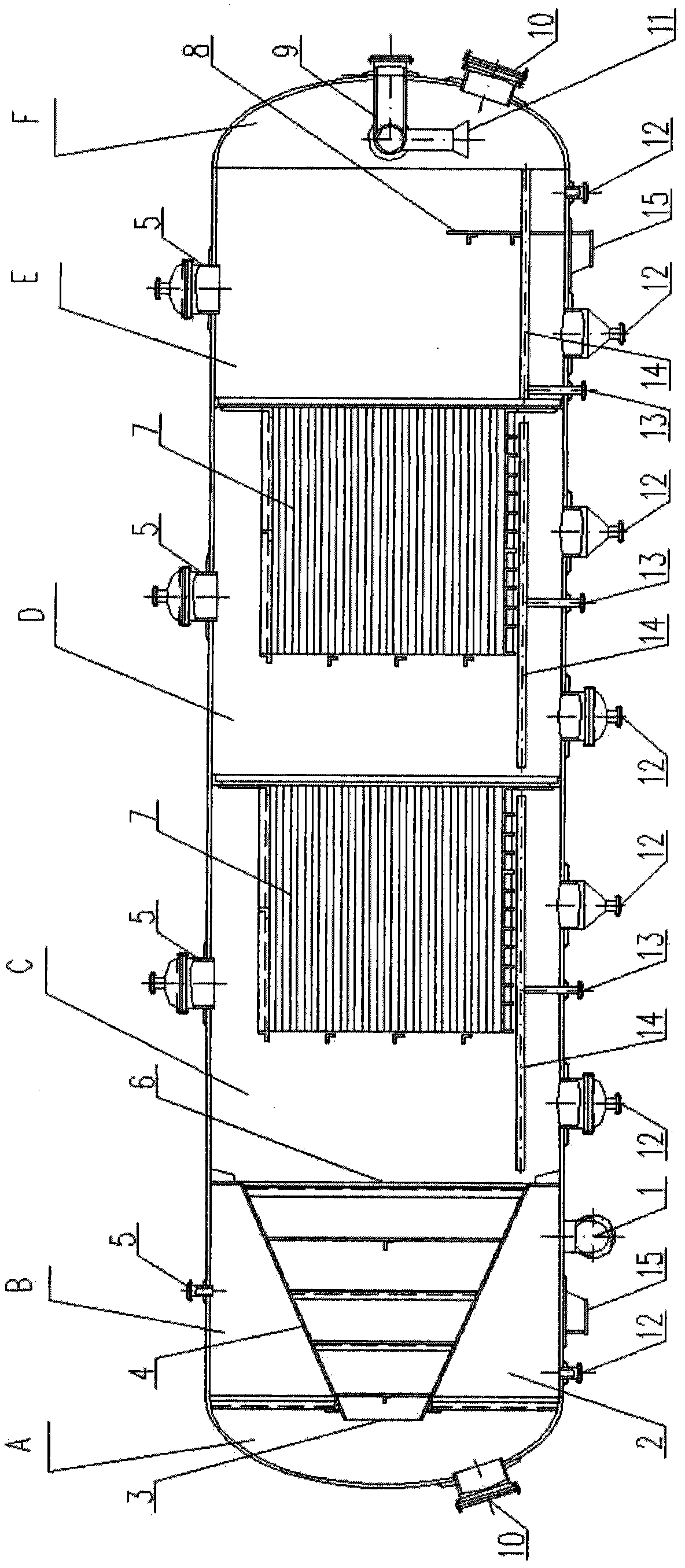

[0017] Such as figure 1 As shown, the present invention includes tank body, water inlet section A, flocculation mixing reaction section B, coalescence separation section C, D, steady flow section E and water outlet section F, water inlet pipe 1, water inlet chamber 2, vortex flocculator inlet Nozzle 3, vortex flocculation reactor 4, oil inlet 5, vortex flocculator outlet 6, corrugated inclined plate group 7, overflow plate 8, water outlet pipe 9, manhole 10, water collection pipe 11, mud discharge port 12, flushing Mouth 13, mud flushing pipe 14, saddle 15. The sewage enters the water inlet chamber 2 from the water inlet pipe 1, and after uniform water distribution, it passes through the water inlet section A and enters the vortex flocculation reactor 4 in the flocculation mixing reaction section B through the water inlet 3 of the vortex flocculator. The size of the front section of the flocculation cylinder is optimized to ensure The vortex effect outside the cylinder, addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com