Soaring sailboat

A technology for sailboats and hulls, applied in the field of sailboats, can solve the problems of unadjustable hydrofoil resistance, no boats, and difficulty in long-distance water navigation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

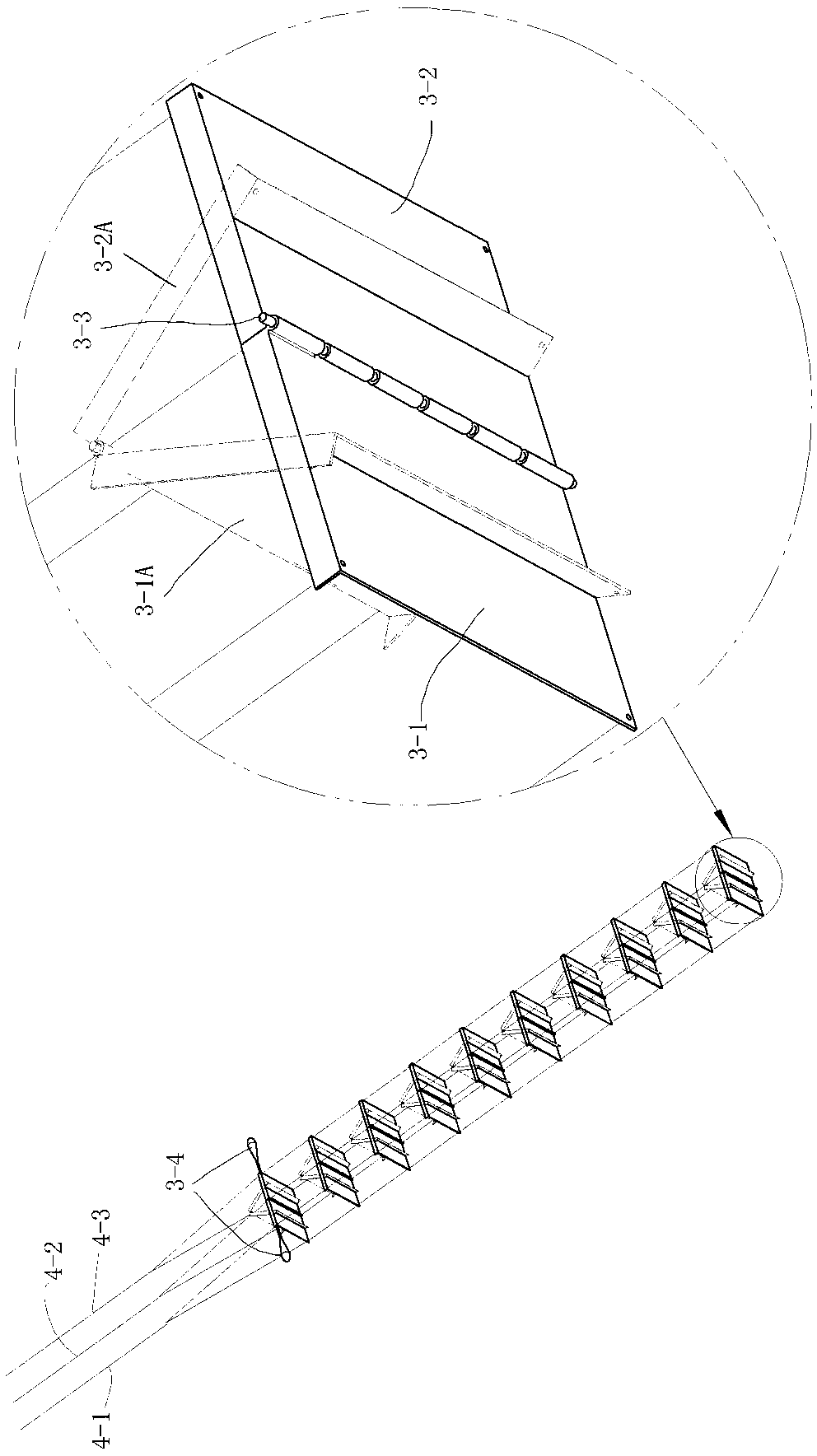

[0016] Embodiment 1: The hull adopts a high-strength flexible structure, and the two sides of the high-elastic closed-cell foam material (2-1) are covered with ultra-high-strength bulletproof fiber cloth (2-2), which is made by pasting and sewing processes, and the sewing thread ( 2-4) Sew the high-elastic closed-cell foam material (2-1) and the ultra-high-strength bulletproof fiber cloth (2-2), and paste or paint the waterproof and anti-seepage material (2-3) on the outside. With spring steel mesh reinforcement (2-5), see figure 2 ; The hull is preferably in the form of a catamaran, and the hull can also be in the form of a monohull or a trimaran. The lifting sail of the soaring sailboat adopts the form of a paraglider (1-1), and its sail control system includes multi-groove wheels (6-2) and direction control cables (6-1), multi-groove wheels (6-3), direction control The winding method of the cable (6-1) on the multi-groove wheel (6-2) and the multi-groove wheel (6-3): fro...

Embodiment approach 2

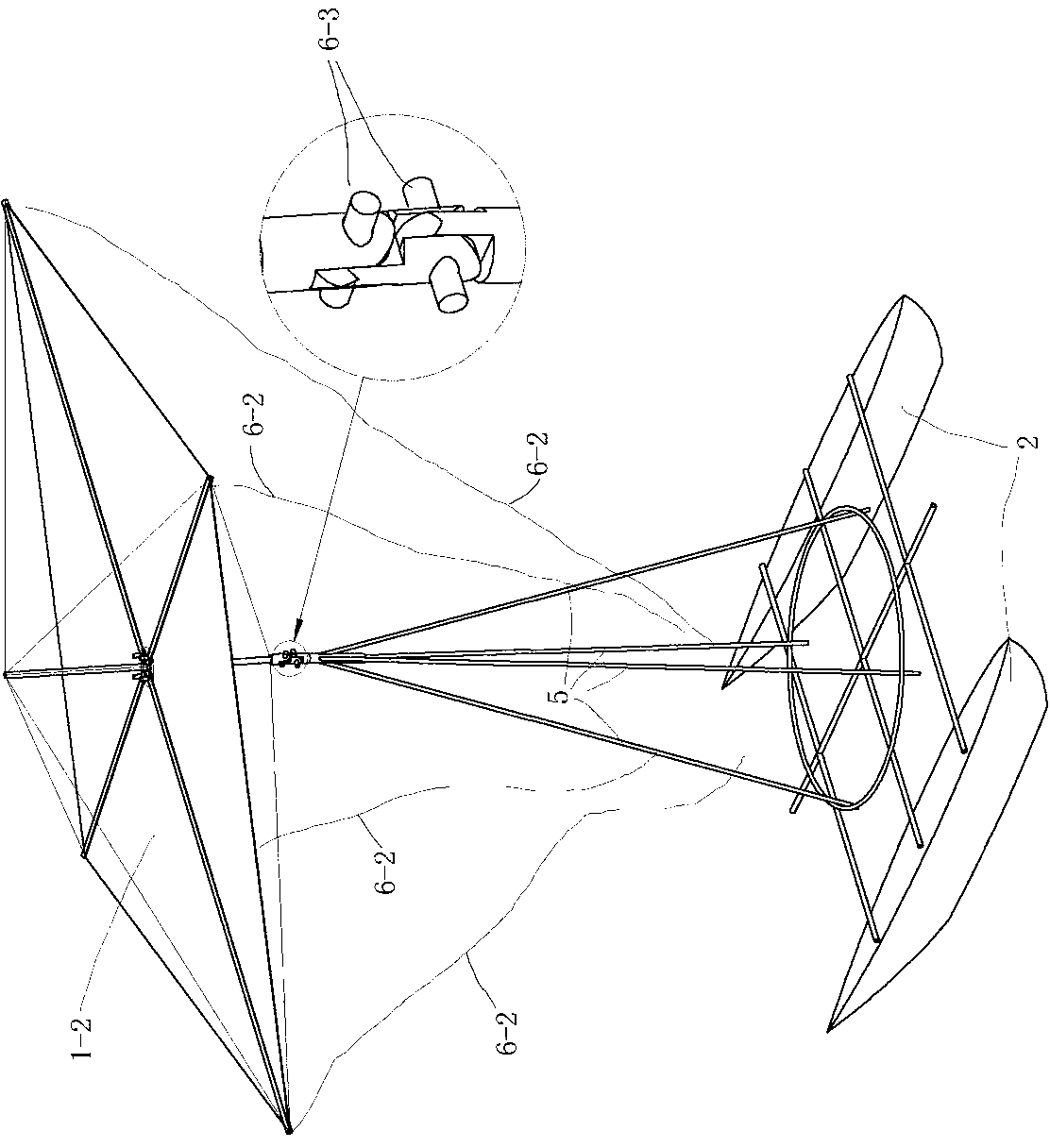

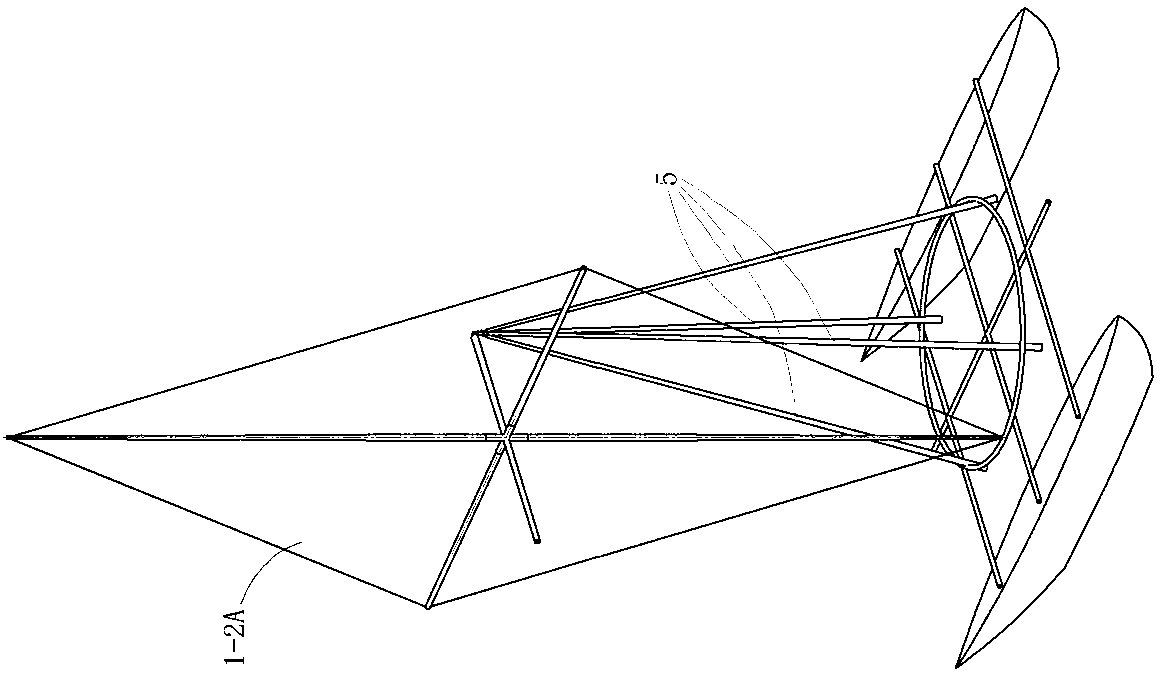

[0017] Embodiment 2: The control cable (6-2) of the rotating form lifting sail (1-2) is connected with the four vertices of the rotating form lifting sail (1-2), and the rotating form lifting sail (1-2) is connected with the mast ( 5) Connected by a universal joint (6-3) or a similar shaft mechanism; when the rotating lift sail is rotated to the vertical position (1-2A), its function is the same as that of a normal sail, see Figure 5 Image 6 The structure of the hull (2) and resistance regulating rudder (3) is the same as embodiment 1.

Embodiment approach 3

[0018] Embodiment 3: The lifting sail of the soaring sailboat adopts the lifting sail in the form of a delta wing (1-3), see Figure 7 , the delta wing is simple in structure and widely used, and the soaring sailboat equipped with the delta wing is stable in flight, and the structure of the hull (2) and the resistance adjusting rudder (3) is the same as that of the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com