Vacuum suction casting equipment and method of high-activity, high-purity and high-melting-point alloy

A vacuum suction casting, high-purity technology, applied in the field of metal material casting metallurgy, can solve the problems of metal type suction casting not suitable for high temperature structure, easy pollution success rate, etc., achieve the effect of short melting time, simple equipment structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

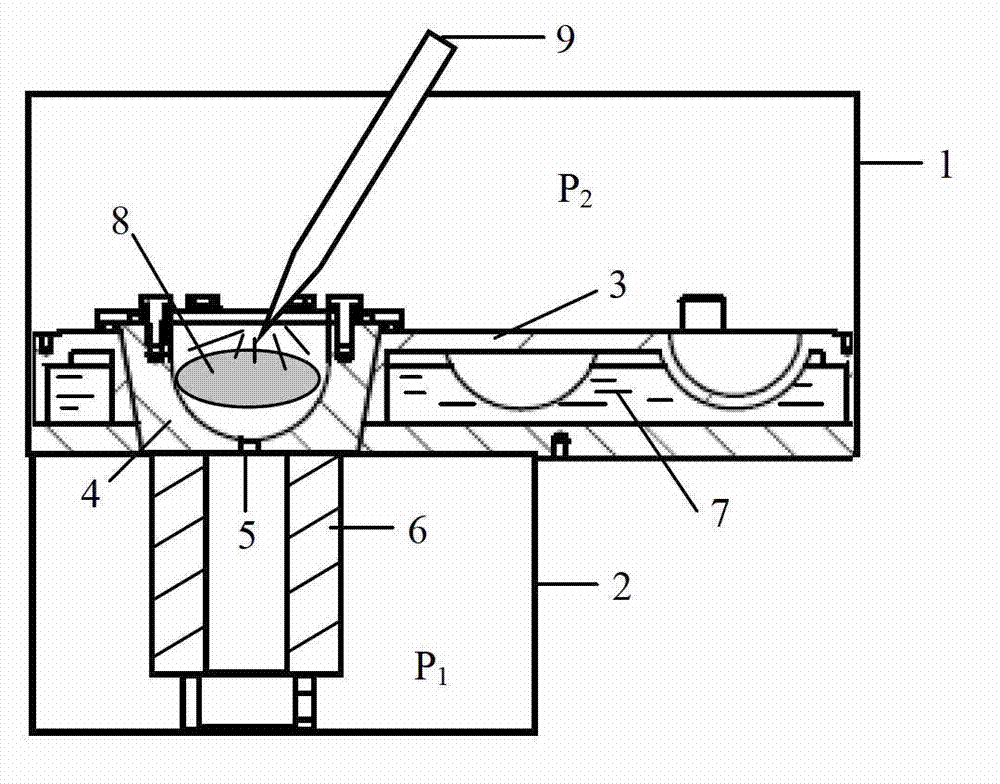

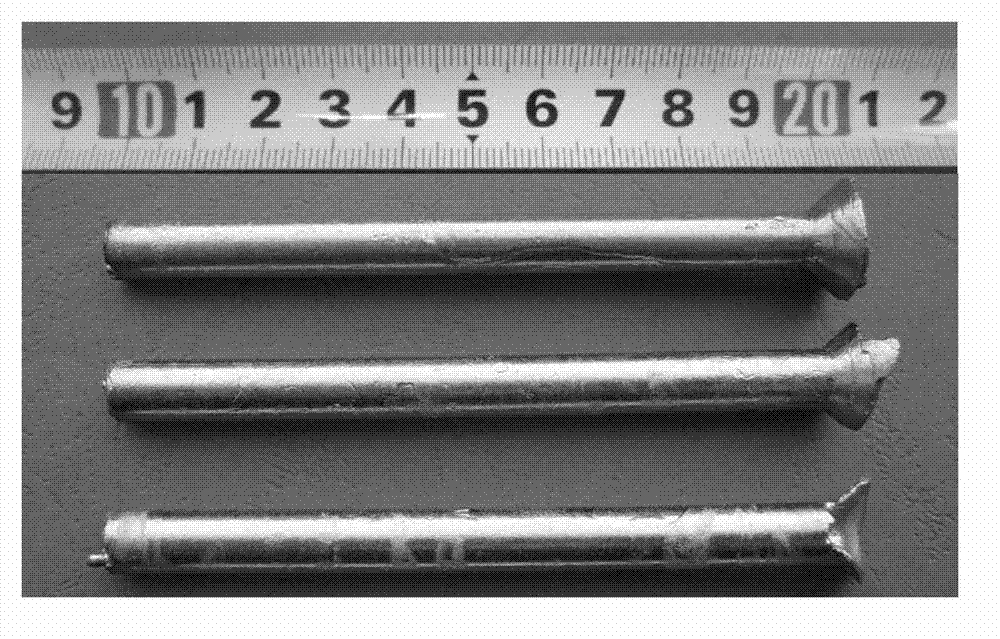

[0038] Put 20-300g of the prepared master alloy ingot 8 into the alloy ingot crucible 4, place the mold 6 in the vacuum chamber 2 directly below it, make the through hole 5 communicate with the upper vacuum chamber and the lower vacuum chamber; close the vacuum chamber 1 and the lower vacuum chamber 2, and simultaneously evacuate to 2×10 -2 Above Pa, then filled with high-purity argon to P 1 Turn on the water circulation 7, turn on the arc torch 9 for argon arc smelting, when the surface layer of the master alloy ingot 8 is completely melted, the through hole 5 will be automatically liquid-sealed to separate the upper vacuum chamber and the lower vacuum chamber; at this time, keep the power of the arc torch unchanged, Continue to fill the vacuum chamber 1 with high-purity argon to P 2 , form the upper and lower pressure difference △P= P 2 -P 1, to ensure that △P is greater than zero; after that, continue to increase the melting power of the arc torch. After a few minutes, t...

Embodiment 2

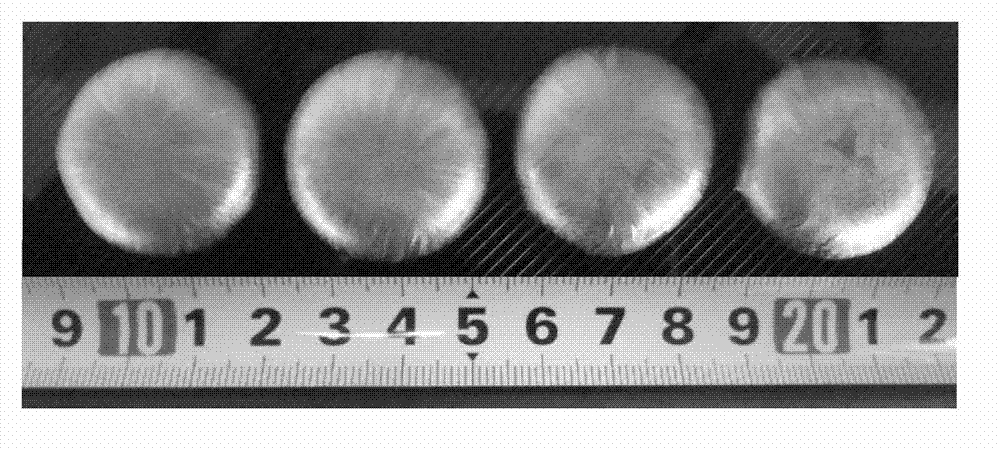

[0040] According to the mass ratio of the alloy components and the law of burning loss compensation, a 10-100g TiAl alloy package is prepared by using high-purity raw materials in a certain proportion, which is placed in a copper crucible 3 and vacuumed to 5×10 -3 Above Pa, then inject high-purity argon gas with a pressure of 0.02-0.06 MPa; perform low-current arcing under visual conditions, and gradually increase the melting current to avoid splashing of raw materials; melt the alloy package evenly and thoroughly with the assistance of electromagnetic stirring , and the arc is closed and solidified into a master alloy ingot; then it is turned over and smelted, and this process is repeated 3-10 times, thereby obtaining a master alloy ingot 8 with high purity, high uniformity and high precision, such as figure 2 As shown, it can be seen from the figure that the prepared master alloy ingot has a smooth surface and good uniformity. After testing, it has high purity and few impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com