Method and device for processing sour gas rich in carbon dioxide in a claus process

A technology of acid gas and carbon dioxide, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of high cost, insufficient high sulfur concentration, etc., and achieve the effect of stable operation guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

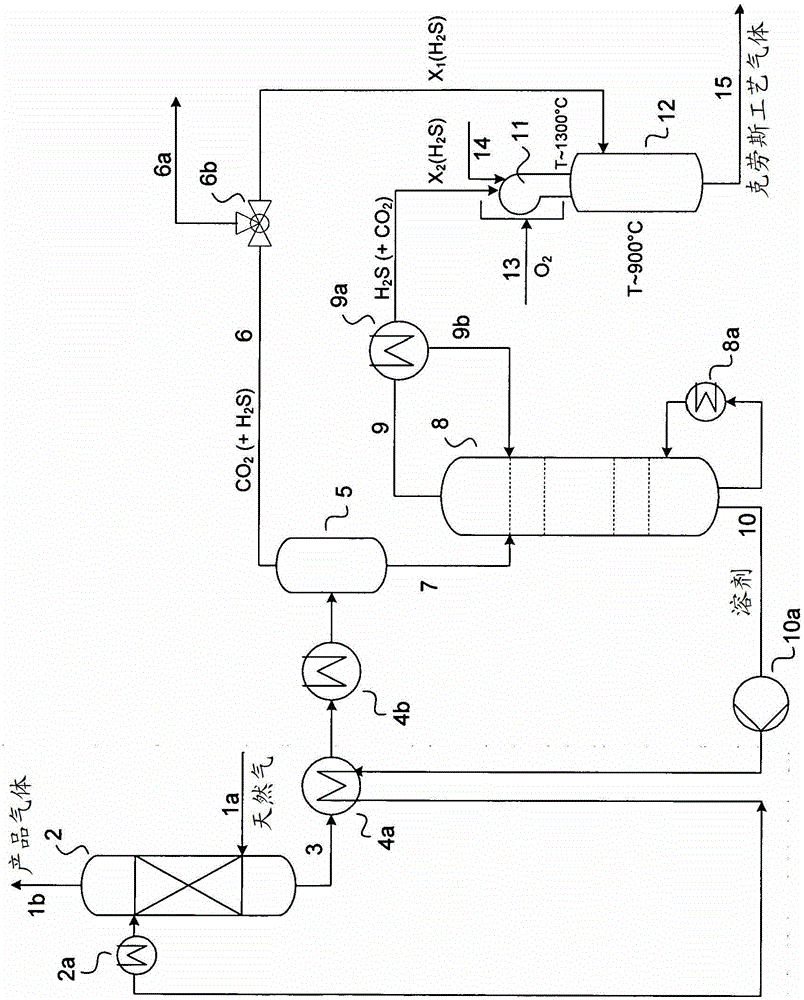

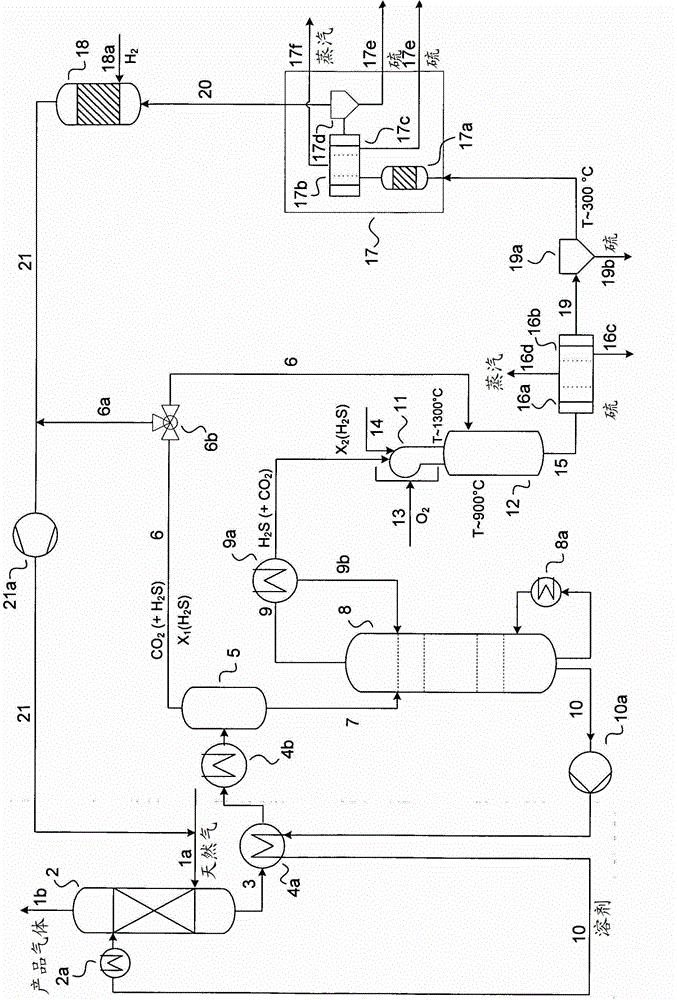

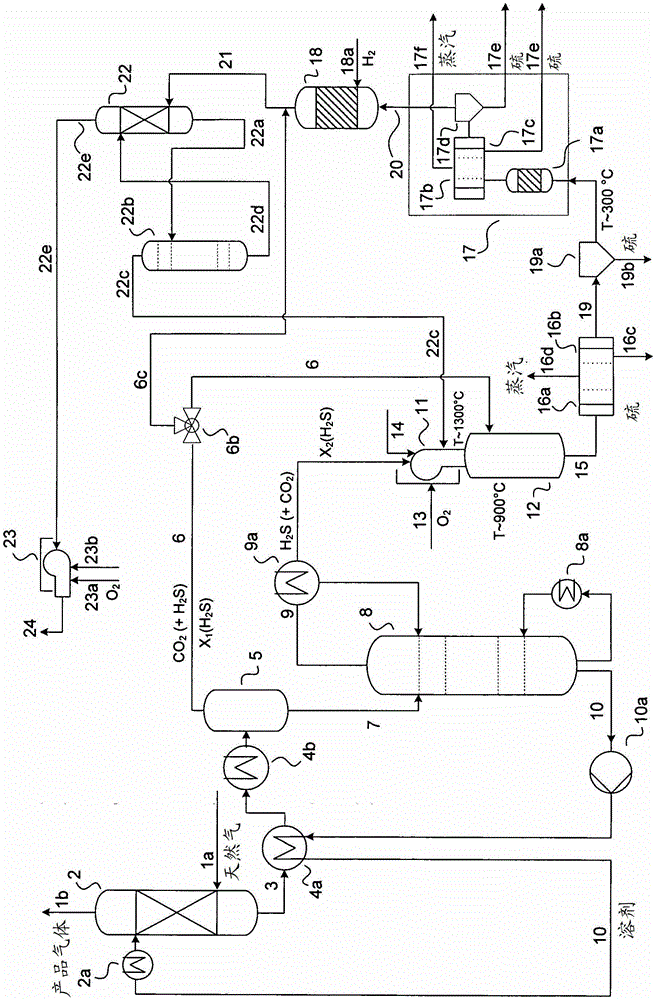

[0053] figure 1A process flow of the present invention is shown. A sulfur-containing process gas 1a to be treated, for example natural gas, is passed through an absorption column 2, where it comes into contact with an absorption solvent cooled by a heat exchanger 2a. This produces a treated product gas 1b that contains little or no sulfur compounds, most of the carbon dioxide contained in the feed gas 1a also remains in the product gas 1b, and the solvent is loaded with Acid gas3. According to the invention, the loaded solvent is preheated by means of heat exchangers 4 a , 4 b and passed to a regeneration unit designed in the form of a flash vessel 5 . Flashing in the flash vessel 5 produces a carbon dioxide-laden, hydrogen sulphide-depleted acid gas fraction 6 depleted in sulfur compounds, and a carbon dioxide-depleted, sulfur-component-rich laden solvent 7 . It is sent to a regeneration column 8, where, in an exemplary mode, heated by a reboiler 8a, the solvent is heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com