Coal-burning boiler dichotomous approach smoke discharging dust removing system

A technology for coal-fired boilers and dust removal systems, applied to lighting and heating equipment, etc., can solve the problems of high cost, increased difficulty in exhausting smoke, and difficulty in exhausting and dedusting, and achieves saving operating costs, good dedusting effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

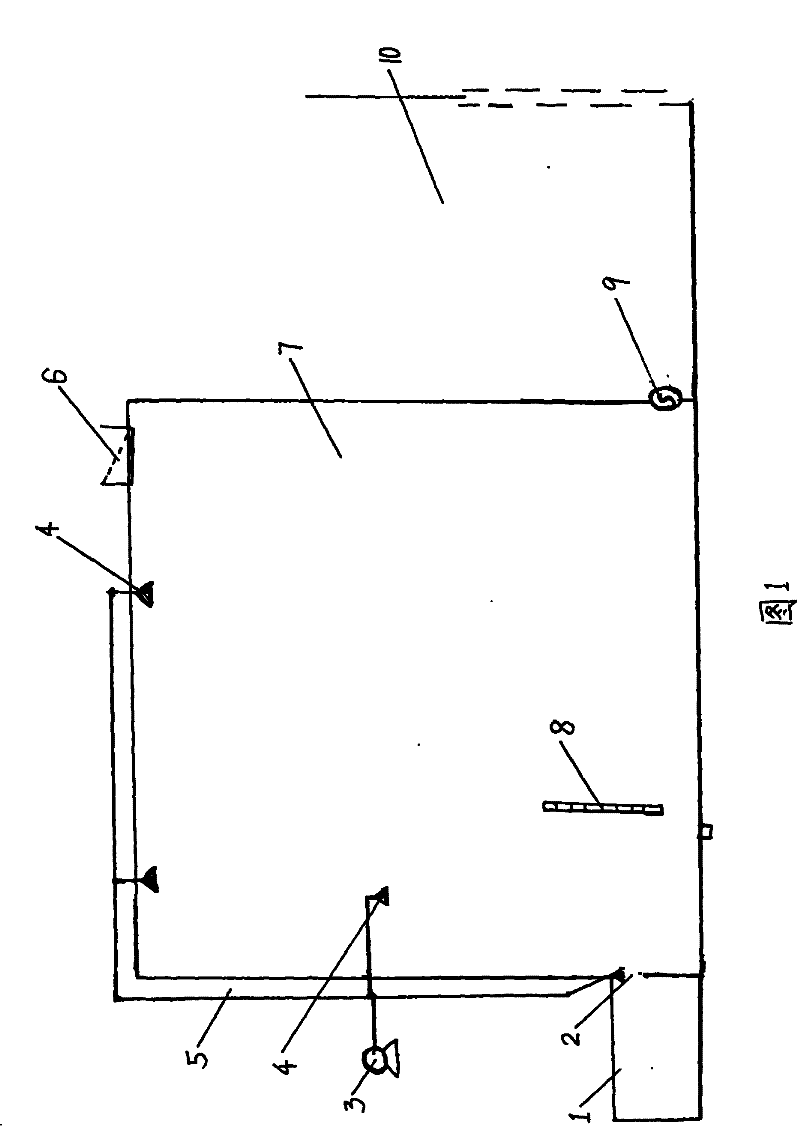

[0013] like figure 1 In the shown coal-fired boiler two-way smoke exhaust and dust removal system, the negative pressure dust removal and desulfurization tower 7 has a flue gas inlet 2 at the front end, and a flue gas outlet at the rear end. The flue gas inlet is directly opposite to the inside of the tower. Four atomizing nozzles 4 are arranged on the wall between the flue gas inlet and the lost wall, on the top of the flue gas inlet and on the top of the tower. The atomizing nozzles are connected to the water pipe 5, and a high-pressure water pump 3 is installed at the water inlet of the water pipe. The high-pressure water pump is connected to the alkali-containing high-pressure water source. An induced draft fan 9 is installed at the outlet of the flue gas. The outlet of the flue gas is connected to the waste gas overflow chamber 10. The smoke outlet has a sealed cover, and the bottom has a sealed ash outlet. The smoke outlet of the coal-fired boiler 1 is connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com