Chemical-mechanical polishing method for simultaneously polishing phase-change material and tungsten

A chemical-mechanical and phase-change material technology, which is applied in the manufacture of polishing compositions containing abrasives, electrical components, semiconductors/solid-state devices, etc., can solve the problems of insufficient polishing rate of substrates, achieve low polishing surface damage, and improve polishing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

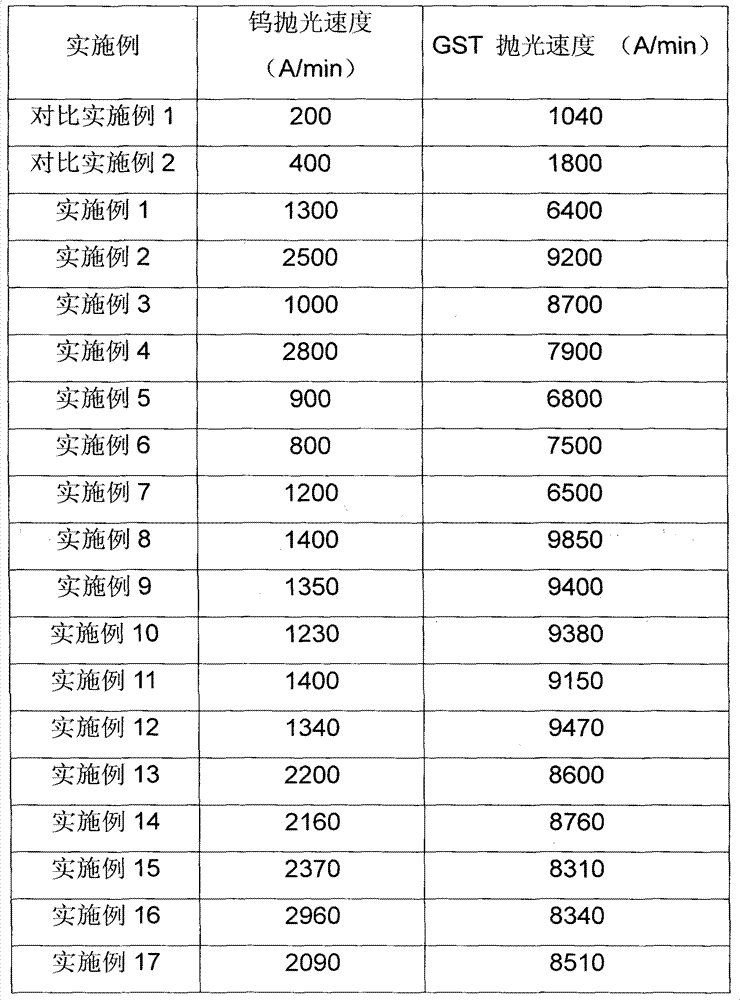

Examples

Embodiment 1

[0027] The abrasive is made of silicon dioxide, the amount of which accounts for 5% of the mass percentage of the entire polishing liquid, and the oxidizing agent is made of 2KHSO 5 ·KHSO 4 ·K 2 SO 4 , its consumption accounts for 1% of the mass percentage of the whole polishing liquid, the concentration of iron nitrate in the polishing liquid is controlled at 1000ppm, and the pH value is adjusted to 1.5 with nitric acid.

[0028] The substrate that needs to be simultaneously polished with phase change materials and tungsten is placed on a polishing pad for chemical mechanical polishing. Polishing conditions: the polishing machine is Logitech (UK) 1PM52 type, polytex polishing pad, 4cm×4cm square wafer (Wafer), The grinding pressure is 4psi, the grinding table speed is 90 rpm, the grinding head rotation speed is 140 rpm, the polishing liquid droplet speed is 140ml / min, and complexing agent, surfactant and other components are added as needed.

Embodiment 2

[0030] The abrasive is made of silicon dioxide, the amount of which accounts for 5% of the mass percentage of the entire polishing liquid, and the oxidizing agent is made of 2KHSO 5 ·KHSO 4 ·K 2 SO 4 , its consumption accounts for 2% of the mass percentage of the whole polishing solution, the concentration of iron nitrate in the polishing solution is controlled at 3000ppm, and the pH value is adjusted to 1.5 with nitric acid.

[0031] Referring to the method described in Example 1, the phase change material and tungsten were simultaneously polished.

Embodiment 3

[0033] The abrasive is made of silicon dioxide, the amount of which accounts for 5% of the mass percentage of the entire polishing liquid, and the oxidizing agent is made of 2KHSO 5 ·KHSO 4 ·K 2 SO 4 , its consumption accounts for 0.1% by mass percentage of the entire polishing liquid, the concentration of iron nitrate in the polishing liquid is controlled at 50 ppm, and the pH value is adjusted to 1.5 with nitric acid.

[0034] Referring to the method described in Example 1, the phase change material and tungsten were simultaneously polished.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com