Improved method for high-pressure resistance test process of endoscope

A high-voltage-resistant, endoscopic technology, which is applied in the field of endoscopic high-voltage-resistant test process improvement, can solve problems such as breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

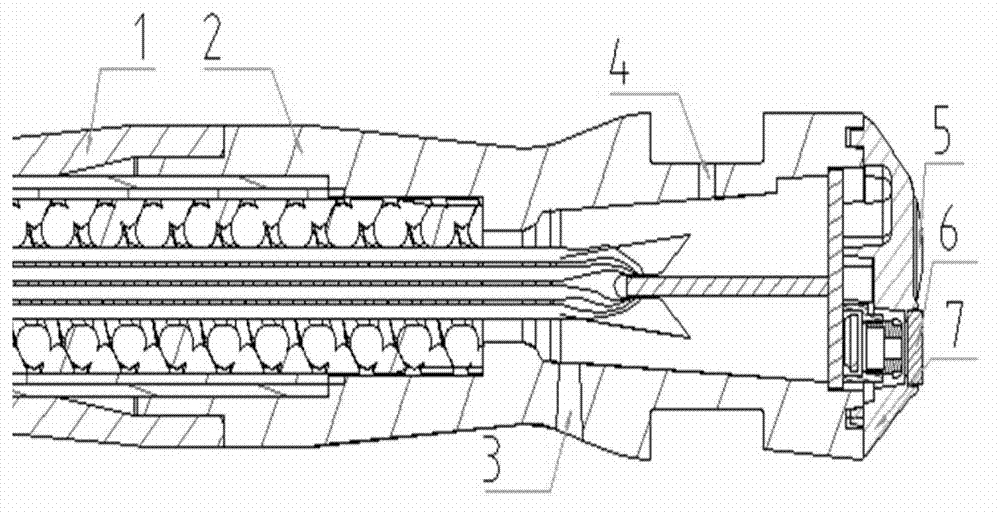

[0025] figure 1 It is a schematic diagram of some components of the lens of the embodiment involved in the present invention, such as figure 1 As shown, the part of the lens assembly to be improved includes an insulating rubber ring 1 , a lens soft stem lower shell 2 , a glue inlet hole 3 , a glue outlet hole 4 , a light guide column 5 , a lens sealing glass 6 and a lens upper shell 7 .

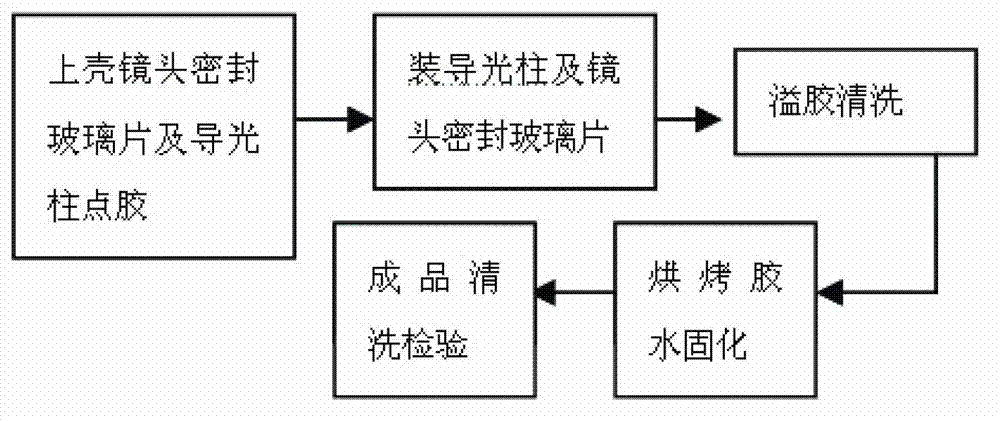

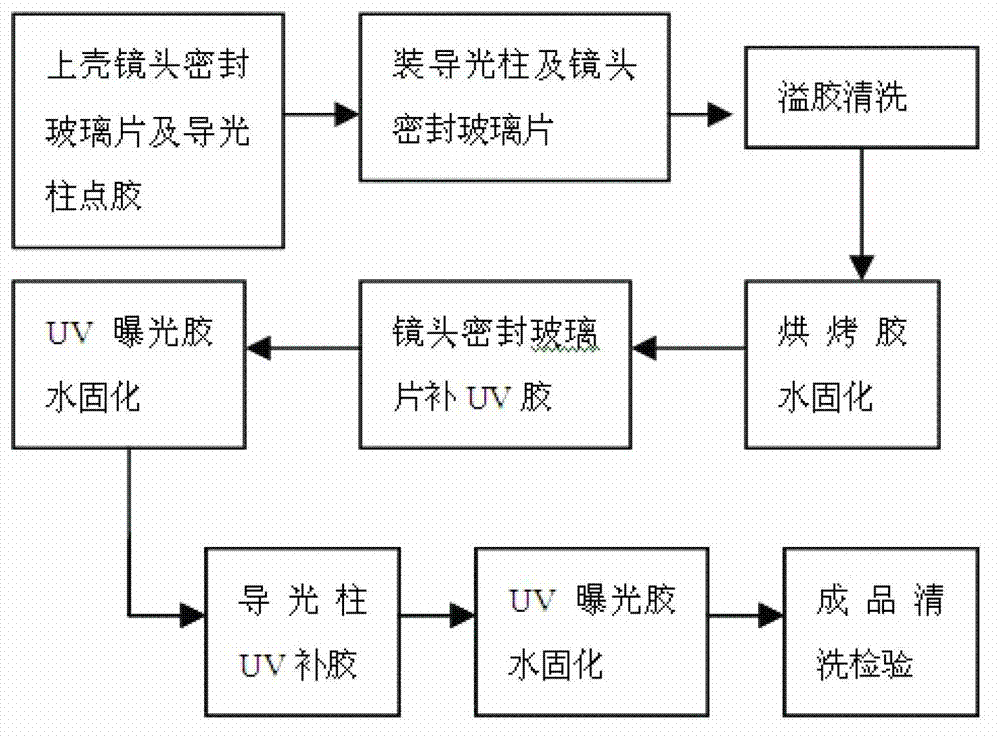

[0026] figure 2 It is the frame diagram of the original installation process of the lens sealing glass 6 and the light guide column 5 at present. After the lens sealing glass 6 and the light guide column 5 are glued, they are installed on the lens upper shell 7, the overflow glue is cleaned, and then the glue is baked and cured. Carry out cleaning inspection of finished products. image 3 It is a frame diagram of the installation process flow of the lens sealing glass 6 and the light guide column 5 in the embodiment of the present invention. After the light guide column 5 and the lens seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com