Condensator and heat radiation net of integrated molding fin type aluminium alloy compound material seamless micropore heat radiating fin

A technology of composite materials and fins, applied in evaporators/condensers, indirect heat exchangers, heat exchanger shells, etc., can solve the problem of high processing cost of small-diameter tubes, not widely used, long small-diameter pipelines and other issues, to achieve the effect of light weight, reduced size and weight, heat transfer coefficient and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

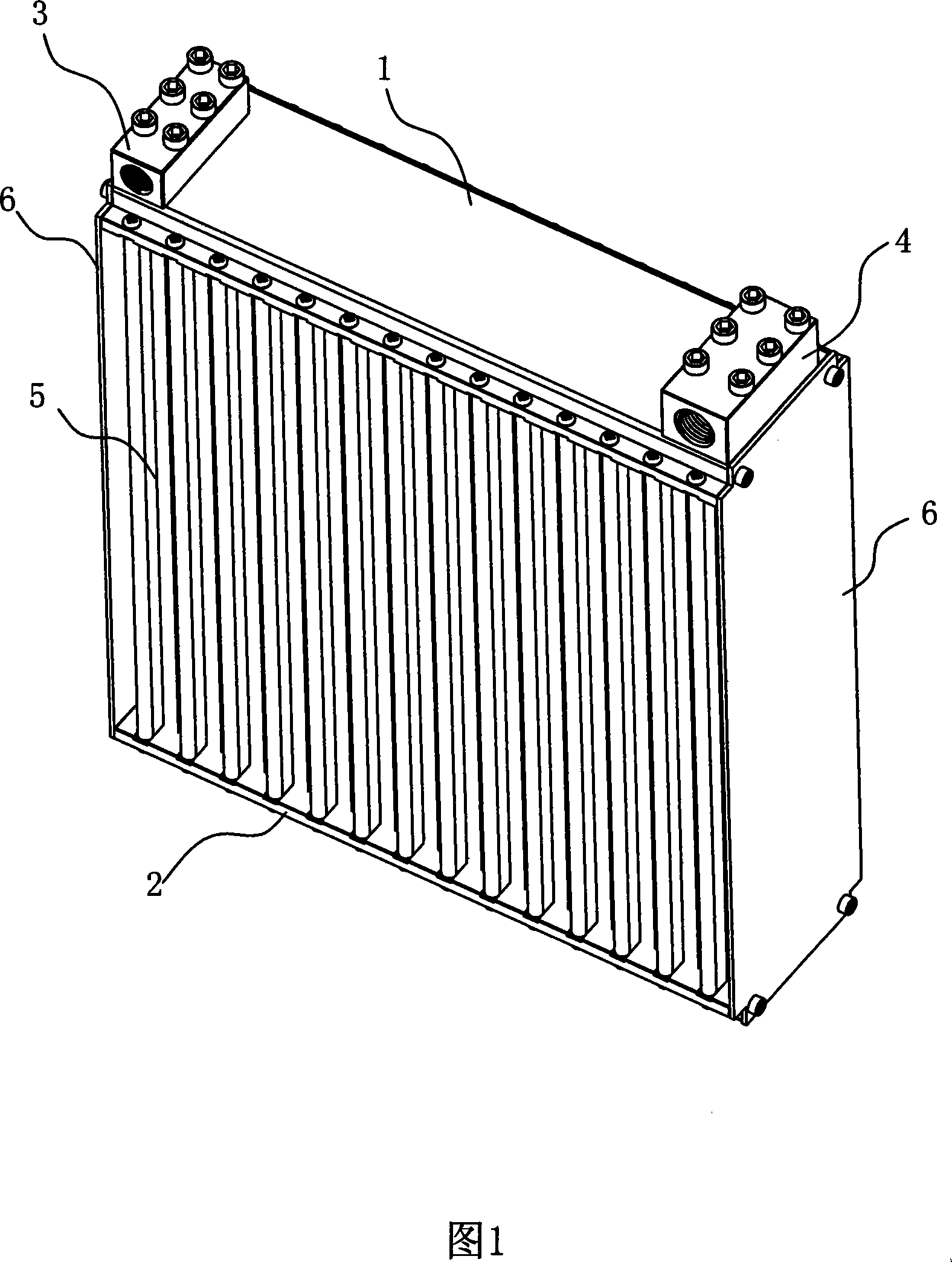

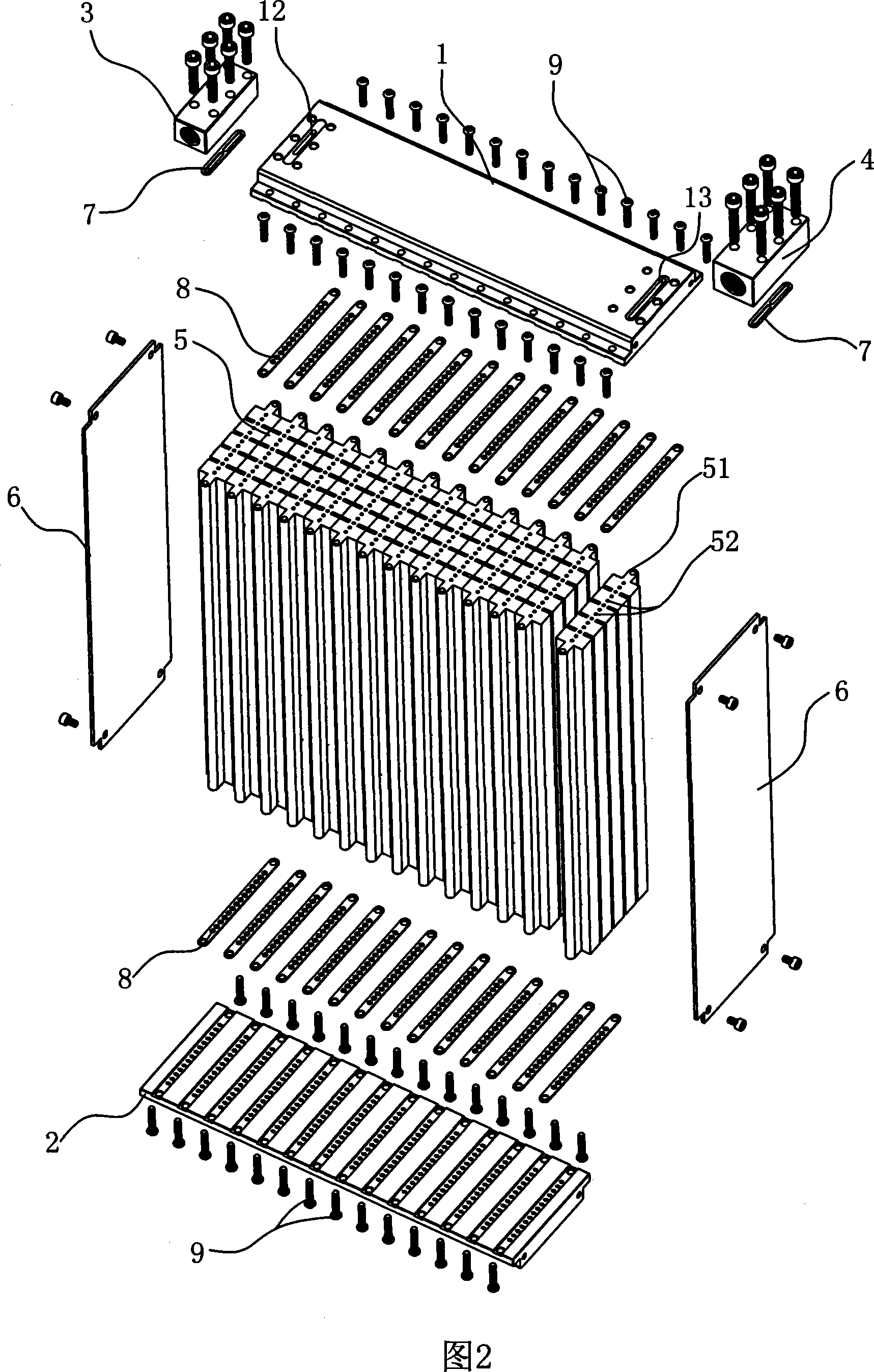

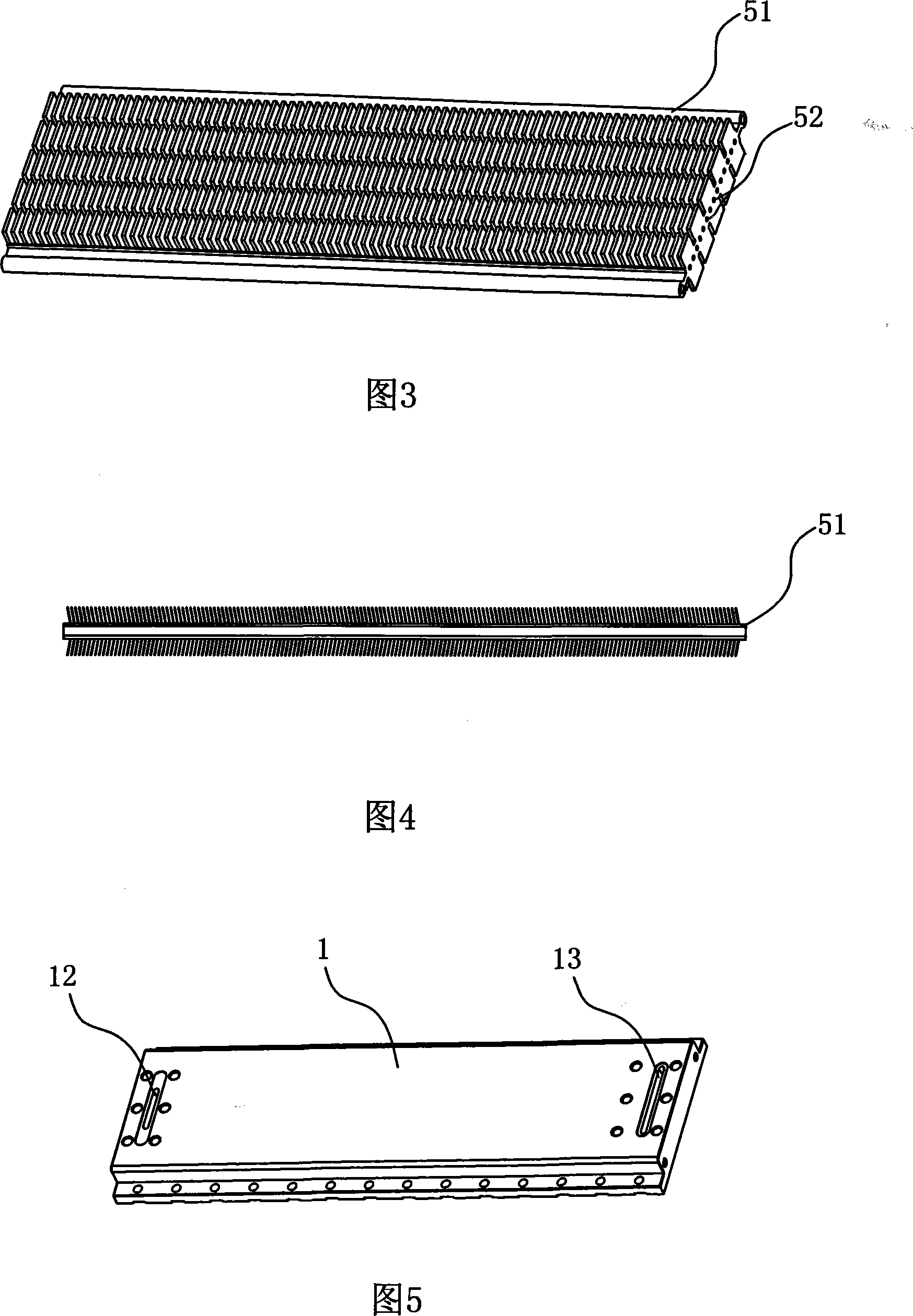

[0031] Below in conjunction with accompanying drawing, the present invention is further described:

[0032] As shown in Figures 1 to 9:

[0033]An integrally formed fin type aluminum alloy composite material seamless microporous heat sink condenser and heat dissipation net, characterized in that it is mainly composed of upper and lower cover plates 1, 2 and a heat sink group 5; the upper and lower cover plates 1.2 Non-welded covers are provided on both ends of the heat sink set 5; the heat sink set 5 is composed of at least two pieces of heat sink 51 side by side, and the heat sink 51 is symmetrical on both sides and evenly distributed with many heat sink fins It is an integrally extruded flat tube aluminum profile with seamless microporous channels, and the upper and lower ends of the heat sink 51 have at least two seamless microholes 52 with uniform distribution through and through, and the diameter of the seamless microholes 52 is 0.9-1MM. The upper and lower cover plates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com