One-step fermentation production process for low molecular weight dextran

A technology for dextran and dextranase, which is applied in the directions of fermentation, microorganism-based methods, microorganisms, etc., can solve the problems of high equipment cost, complicated production process, and high technical literacy requirements of production personnel, and achieves simple equipment, simplified technological process, and technical difficulty. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention discloses a method for producing dextran by fermentation of Leuconostoc enterococcus.

[0034] 1) Activation of strains: activation of Leuconostoc enterica 20074 on a slant, cultured in an incubator at 28°C for 2 days;

[0035] 2) Primary seed culture: connect the Leuconostoc enterococcus grown on the slant to a 250mL Erlenmeyer flask with an inoculation loop, in which 100mL contains 0.14g of disodium hydrogen phosphate, 13g of sucrose, 0.2g of peptone, The liquid medium of potassium dihydrogen phosphate 0.03g was cultivated to OD under the conditions of rotation speed 100rpm and temperature 28°C 600 It is about 0.8 as a first-level seed;

[0036] 3) Secondary seed cultivation: put the first-stage seeds into the Erlenmeyer flask containing the above-mentioned liquid medium with 20% inoculum amount, and cultivate to OD at the speed of 100rpm and the temperature of 28°C. 600 0.8 or so is the secondary seed;

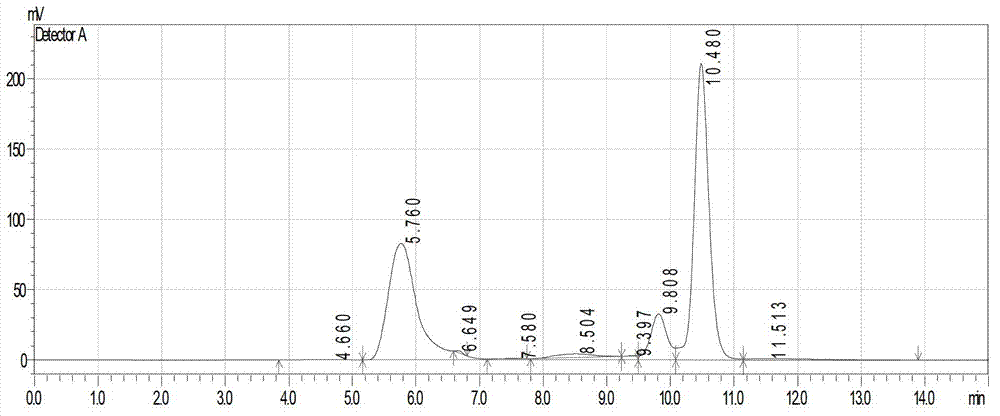

[0037] 4) Put the secondary seeds into a 5L au...

Embodiment 2

[0043] Method 1 for the one-step directed production of micromolecular dextran by enzymatic hydrolysis and cooperative fermentation.

[0044] 1) Strain activation: Leuconostoc enterococcus GSICC 31208 was activated on a slant, and cultured in an incubator at 28°C for 2 days;

[0045]2) Primary seed culture: connect the Leuconostoc enterococcus grown on the slant to a 250mL Erlenmeyer flask with an inoculation loop, in which 100mL contains 0.14g of disodium hydrogen phosphate, 13g of sucrose, 0.2g of peptone, The liquid medium of potassium dihydrogen phosphate 0.03g was cultivated to OD under the conditions of rotation speed 100rpm and temperature 28°C 600 It is about 0.8 as a first-level seed;

[0046] 3) Secondary seed cultivation: put the first-stage seeds into the Erlenmeyer flask containing the above-mentioned liquid medium with 20% inoculum amount, and cultivate to OD at the speed of 100rpm and the temperature of 28°C. 600 0.8 or so is the secondary seed;

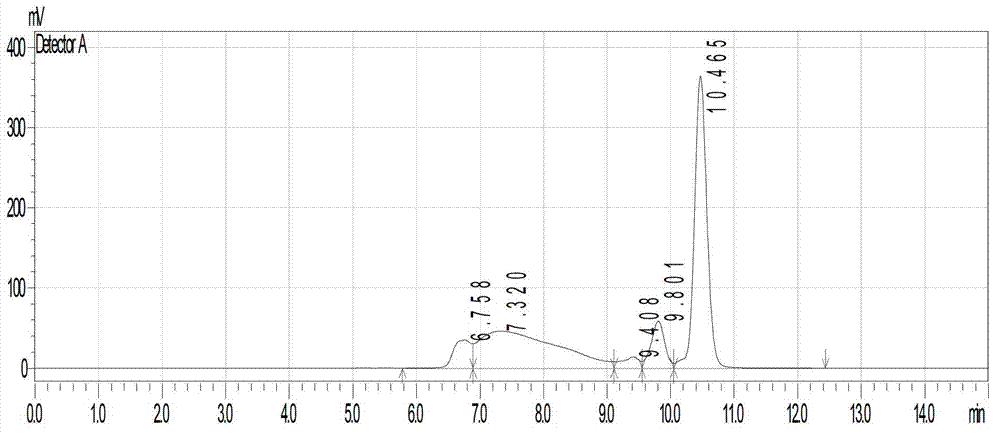

[0047] 4) P...

Embodiment 3

[0051] Method 2 for the directional production of micromolecular dextran by enzymatic hydrolysis and cooperative fermentation one-step method.

[0052] 1) Activation of strains: activation of Leuconostoc enterica 20074 on a slant, cultured in an incubator at 28°C for 2 days;

[0053] 2) Primary seed culture: connect the Leuconostoc enterococcus grown on the slant to a 250mL Erlenmeyer flask with an inoculation loop, in which 100mL contains 0.14g of disodium hydrogen phosphate, 13g of sucrose, 0.2g of peptone, The liquid medium of potassium dihydrogen phosphate 0.03g was cultivated to OD under the conditions of rotation speed 100rpm and temperature 28°C 600 It is about 0.8 as a first-level seed;

[0054] 3) Secondary seed cultivation: put the first-stage seeds into the Erlenmeyer flask containing the above-mentioned liquid medium with 20% inoculum amount, and cultivate to OD at the speed of 100rpm and the temperature of 28°C. 600 0.8 or so is the secondary seed;

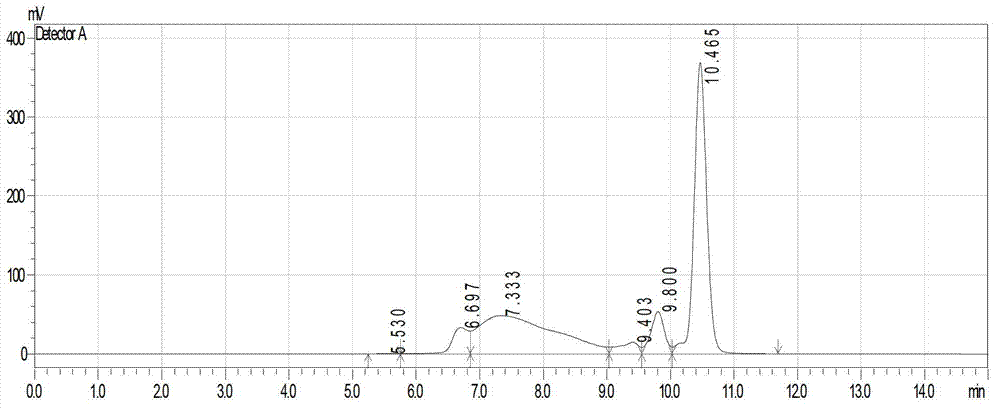

[0055] 4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com