Preparation method of composite hollow silicate

A silicate and hollow technology, which is applied in the field of silicate, can solve the problems of less research on composite hollow silicate materials, and achieve the effects of easy post-processing, mild reaction conditions, and simple synthesis reaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

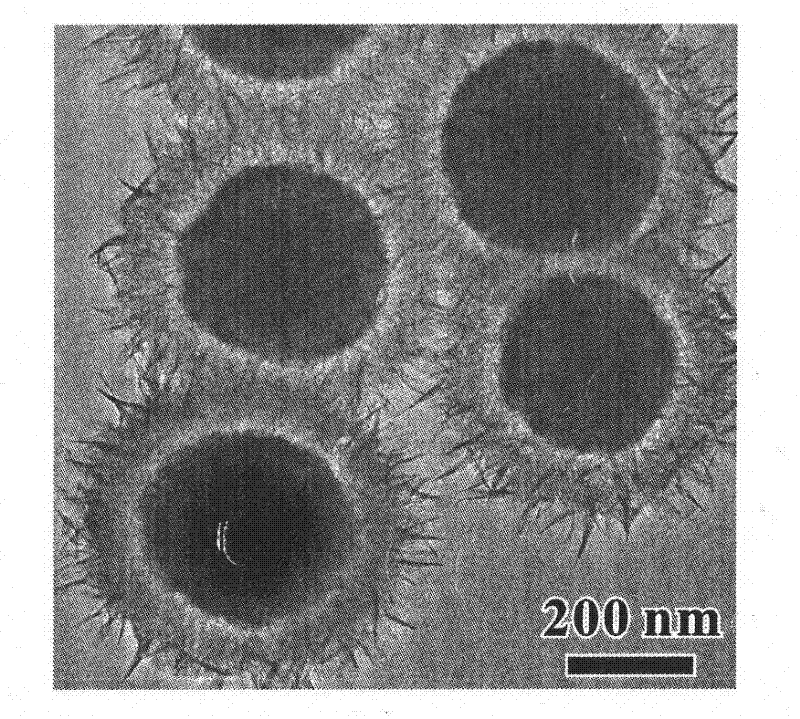

[0020] Embodiment 1: Add 10mL water, 5mL ethanol in 25mL polytetrafluoroethylene liner, then add 25mgFe 3 o 4 SiO 2 , 0.675g urea and 0.064g magnesium nitrate hexahydrate were added. Put the polytetrafluoroethylene liner in the reaction kettle, and keep the temperature at 190°C for 36h. After the reaction was completed and cooled to room temperature, the obtained solid product was washed three times with water and ethanol respectively to obtain the target product. The morphology of the product was systematically studied by transmission electron microscope analysis technology. Such as figure 1 The obtained Fe can be analyzed by transmission electron microscopy characterization as shown 3 o 4 It is a composite hollow product with core and magnesium silicate as shell.

Embodiment 2

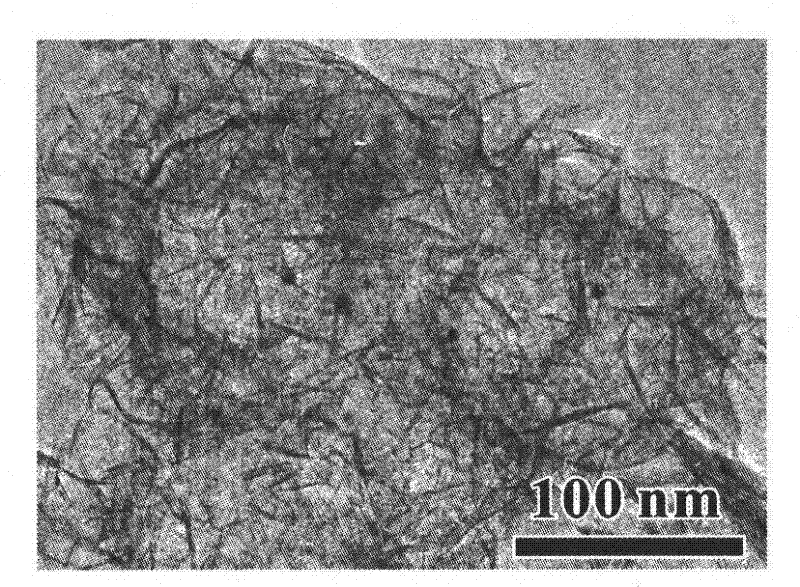

[0021] Example 2: Add 10mL water and 5mL ethanol to 25mL polytetrafluoroethylene lining, and then add 25mgAuSiO 2 , 0.675g urea and 0.073g nickel nitrate hexahydrate were added. Put the polytetrafluoroethylene liner in the reaction kettle, and keep the temperature at 190°C for 36h. After the reaction was completed and cooled to room temperature, the obtained solid product was washed three times with water and ethanol respectively to obtain the target product. The morphology of the product was systematically studied by transmission electron microscope analysis technology. Such as figure 2 The resulting composite hollow product with Au as the core and nickel silicate as the shell can be analyzed by transmission electron microscopy.

Embodiment 3

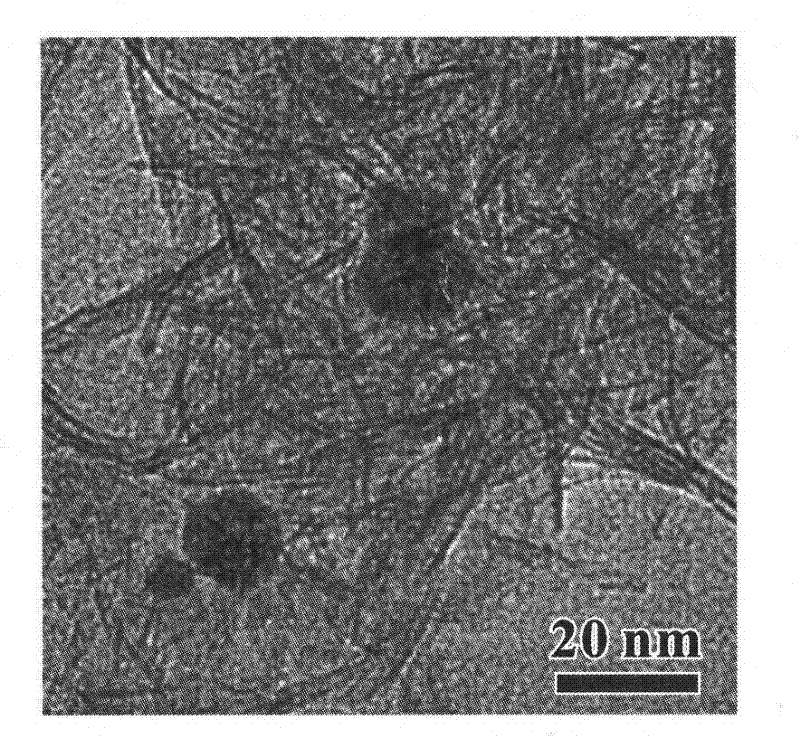

[0022] Embodiment 3: add 10mL water, 5mL ethanol in 25mL polytetrafluoroethylene liner, then add 25mgFe 3 o 4 / Pd, 0.675g urea and 0.064g magnesium nitrate hexahydrate were added. Put the polytetrafluoroethylene liner in the reaction kettle, and keep the temperature at 190°C for 36h. After the reaction was completed and cooled to room temperature, the obtained solid product was washed three times with water and ethanol respectively to obtain the target product. The morphology of the product was systematically studied by transmission electron microscope analysis technology. Such as image 3 The composite hollow product with Fe3O4 / Pd as the core and magnesium silicate as the shell can be analyzed by transmission electron microscopy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com