Method for synthesizing beta-amidocarbonyl compounds

A technology of carbonyl compounds and compounds, which is applied in the field of synthesizing β-amide carbonyl compounds, can solve the problems of expensive catalysts, narrow substrate range, and high temperature, and achieve the effects of cheap and easy-to-obtain catalysts, mild reaction conditions, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

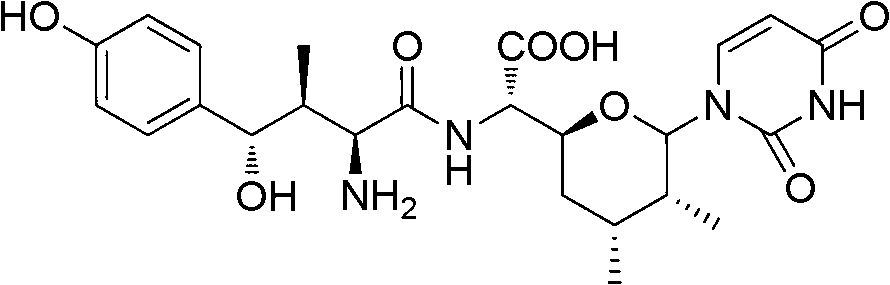

Image

Examples

example example 1

[0032] Add 5ml of dried acetonitrile to a 25ml round bottom flask, add 2mmol of benzaldehyde, 2mmol of acetophenone, and then add 1.5ml of acetyl chloride and 2mmol of TiCl under stirring 4 , the mixed solution was stirred and reacted for 3h. After the reaction was completed, the reaction solution was poured into 25ml of ice-water mixture, a mixture of oil and solid was separated out, and the product was separated by column chromatography, ethyl acetate:petroleum ether (1:1, v :v), N-(3-oxo-1,3-diphenylpropyl)acetamide (1) was obtained with a yield of 90%, Mp103-104°C. Benzaldehyde and acetophenone, the reaction formula of acetonitrile is:

[0033]

[0034] The spectral data of product (1) is: 1 H NMR (400MHz, CDCl 3 )δ:2.00(3H,s,COCH 3 ),3.42(1H,dd,J 6.0,16.8Hz,CH 2 ),3.71(1H,dd,J 4.8,17.2Hz,CH 2),5.49-5.54(1H,m,CH),6.60(1H,d,J 8.4Hz,NH),7.27-7.30(5H,m,Ph),7.44(2H,t,J 8.0Hz,Ph), 7.56(1H,t,J 7.2Hz,Ph),7.88(2H,d,J8.4Hz,Ph);IR(film)ν max 3275,3082,2926,1693,1646,1552,...

Embodiment 2

[0036] Replace benzaldehyde with p-chlorobenzaldehyde, and others are with embodiment 1. The target compound (2) was obtained with a yield of 96%, Mp143-145°C. p-Chlorobenzaldehyde and acetophenone, the reaction formula of acetonitrile is:

[0037]

[0038] The spectral data of product (2) is: 1 H NMR (400MHz, CDCl 3 )δ:2.04(3H,s,COCH 3 ),3.42(1H,dd,J 6.4,17.2Hz,CH 2 ),3.74(1H,dd,J 4.8,17.2Hz,CH 2 ),5.52–5.59(1H,m,CH),6.77(1H,d,J 8.0Hz,NH),7.26–7.27(4H,m,Ph),7.46(2H,t,J 7.6Hz,Ph), 7.59(1H,t,J 7.2Hz,Ph),7.85(2H,d,J7.6Hz,Ph);IR(film)ν max 3289,3084,2926,1686,1651,1551,1372,1199,987,757cm -1 ;MS(ESI):m / z(relative intensity)224.1([M+Na] + ,100).

Embodiment 3

[0040] P-fluorobenzaldehyde was used instead of benzaldehyde, and the others were the same as in Example 1 to obtain the target compound (3), with a yield of 93%, Mp 108-111°C. p-Fluorobenzaldehyde and acetophenone, the reaction formula of acetonitrile is:

[0041]

[0042] The spectral data of product (3) is: 1 H NMR (400MHz, CDCl 3 )δ:2.04(3H,s,COCH 3 ),3.43(1H,dd,J 6.0,16.8Hz,CH 2 ),3.75(1H,dd,J 5.2,17.2Hz,CH 2 ),5.52–5.58(1H,m,CH),6.77(1H,d,J 5.6Hz,NH),6.97-7.01(2H,m,Ph),7.30-7.33(2H,m,Ph),7.47( 2H,t,J 7.6Hz,Ph),7.59(1H,t,J 7.2Hz,Ph),7.91(2H,d,J 8.0Hz,Ph);IR(film)ν max 3286,3082,2956,2844,1687,1648,1550,1508,1371,1226,990,751cm -1 ;MS(ESI):m / z(relative intensity)308.0([M+Na] + ,100).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com