Lower die blanking structure with scrap jumping prevention function

A blanking and chip-jumping technology, which is applied in the field of mechanical processing, can solve problems such as knife edge cracking, template cracking, and chipping, and achieve the effects of preventing jumping out of the mold surface, low cost, and avoiding the impact of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

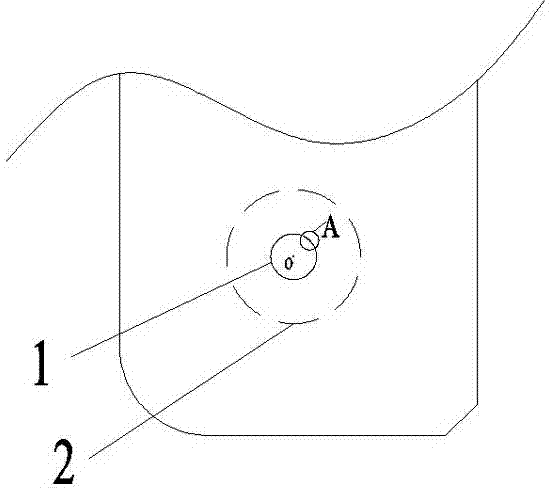

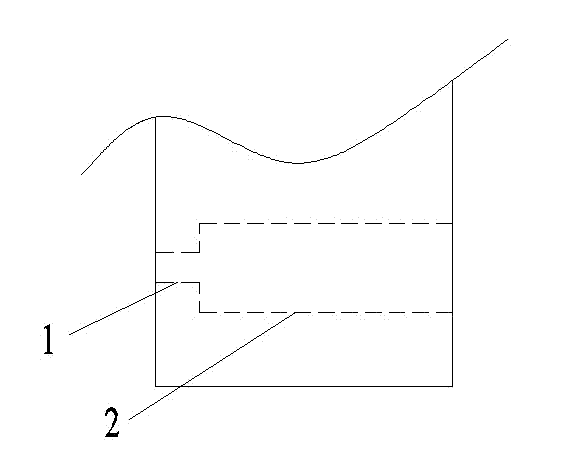

[0015] see figure 1 and figure 2 , the blanking structure of the lower mold for preventing chip skipping of the present invention includes: a blanking area 1 and a chip storage area 2 located below the blanking area 1, the section of the blanking area 1 is a non-true circle, and the section of the chip storage area 2 It is circular, and the cross-section of the blanking area 1 is smaller than the cross-section of the debris storage area 2.

[0016] Among them, the cross section of the blanking area 1 is non-circular, so that the waste chips are deformed, which effectively avoids the traditional shape of waste chips, such as the round waste chips that rotate during the blanking process, resulting in the problem of chip jumping.

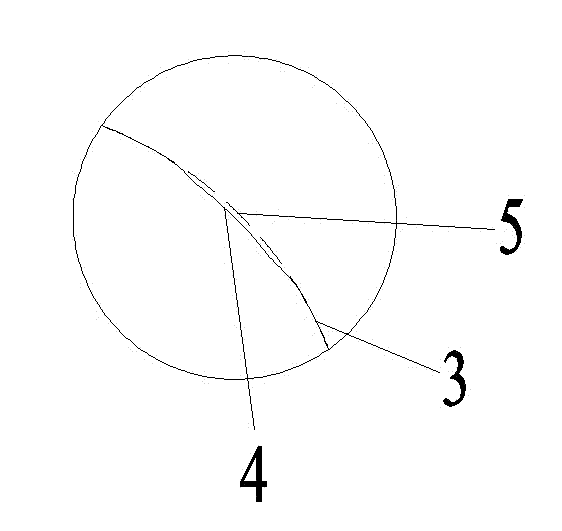

[0017] Specifically, see figure 1 and image 3 , the outline of a non-true circle includes: multiple arcs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com